Every high-performance graphics processor relies on a solid foundation - the PCB video card. While the GPU chip often grabs attention, it’s the printed circuit board (PCB) that determines how power, data, and heat are managed across the system. Without an optimized PCB, even the most advanced silicon will fail to achieve its potential.

In this article, we’ll dive into how modern PCB design, material selection, and precision manufacturing elevate GPU architecture to a reliable, high-speed video card - the heart of gaming, rendering, and AI computing.

1. The Role of a PCB in Video Card Design

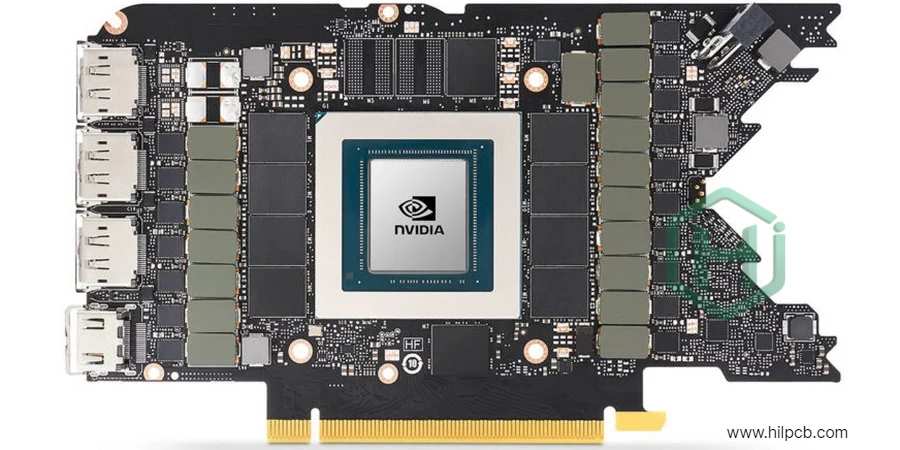

The PCB in a video card is not just a passive base but serves as both the structural frame and the electrical backbone of the GPU assembly. Its primary functions include:

Component Integration

A PCB video card integrates and connects all critical components:

- GPU core (die + package)

- GDDR memory modules

- Voltage Regulator Modules (VRMs)

- PCIe and display connectors

- Fan controllers and monitoring ICs

Every trace and via on the PCB is engineered to ensure signal integrity, maintain proper timing, and prevent electromagnetic interference, enabling smooth communication between the GPU and memory modules.

Signal & Power Distribution

The PCB channels multiple high-speed signals across micro-thin copper layers, ensuring reliable, gigahertz-range data transmission. At the same time, power is delivered through dedicated copper planes, specifically designed for low impedance and high current density, minimizing ripple and noise that could destabilize the GPU.

For efficient power integrity, engineers use carefully routed copper planes to optimize the power distribution system, ensuring consistent performance even under heavy loads.

Structural and Thermal Integrity

Beyond electrical functions, the PCB provides physical rigidity to support large heatsinks and backplates. Materials such as high-Tg FR4, polyimide, and BT epoxy composites are carefully selected for their thermal stability and mechanical endurance under prolonged load cycles.

The high-TG PCB material ensures that the video card can withstand the heat generated by the GPU, ensuring stable operation even under extended usage.

2. Engineering Principles Behind PCB Video Cards

Designing a high-performance video card PCB is about balancing speed, efficiency, thermal management, and cost. Each design aspect requires precise control and engineering.

Signal Integrity (SI)

At data rates exceeding 10 Gbps, even tiny imperfections in the PCB design can cause reflection, timing errors, and degraded signal quality. To prevent this, engineers implement:

- Controlled impedance traces (e.g., 85 Ω differential impedance)

- Length matching (within ±5% tolerance)

- Ground shielding and differential pair routing

- Backdrilling to remove via stubs that reflect signals

These methods are crucial to maintaining clean data transmission between the GPU, VRAM, and output interfaces, ensuring high-speed communication for gaming and rendering tasks.

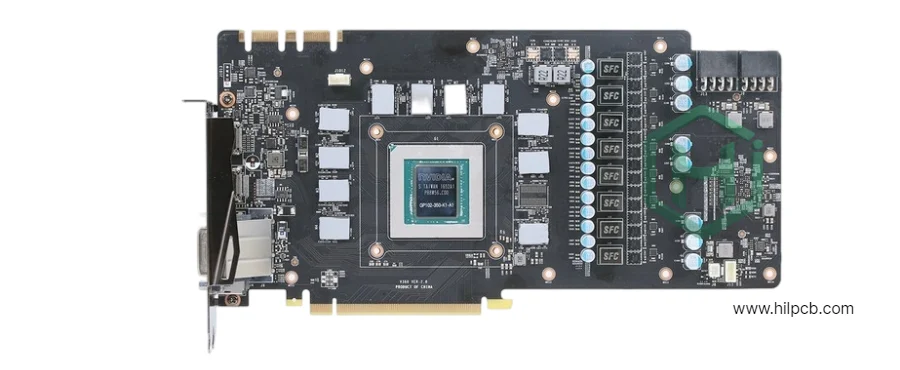

Power Integrity (PI)

Modern GPUs draw 200-400 W or more under full load. Consequently, the PCB video card must manage transient currents while maintaining stable voltage. Key features for power integrity include:

- Multi-phase VRM architecture (10-20 phases)

- Low-ESR polymer capacitors for ripple absorption

- Wide copper pours and thermal vias for current handling

- Optimized plane stacking for low inductance return paths

For optimal power distribution, multilayer PCBs are used, ensuring stable power delivery across the card, even under maximum load.

Thermal Management

A high-performance PCB also acts as a thermal conduit. Engineers integrate:

- Thick copper layers (2-4 oz) for efficient heat spreading

- Thermal vias beneath VRMs and the GPU die

- Metal backplates or secondary PCBs for heat dissipation

These elements prevent thermal hotspots and help maintain the board’s efficiency, especially during long gaming sessions or demanding tasks. For efficient thermal management, using high-thermal PCBs is critical to handle the heat generated by the high-speed components.

EMI and Crosstalk Reduction

Electromagnetic interference (EMI) is a significant concern for high-speed systems. To mitigate this:

- Layered stack-ups are designed to suppress EMI

- Alternating ground and signal layers create natural shielding

- Ferrite beads, decoupling networks, and guard traces contain switching noise from VRMs and memory interfaces

Optimizing these layers ensures signal integrity and EMI suppression, crucial for maintaining smooth video output.

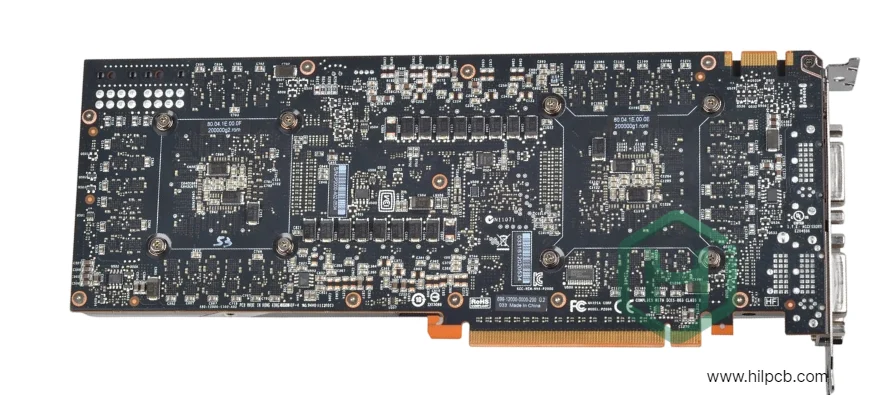

3. Inside the PCB Stack-Up of a Video Card

A modern PCB video card typically uses 8 to 12 layers, each serving a distinct function:

| Layer | Function | Description |

|---|---|---|

| 1 | Component / Top Signal | Mounts key components such as the GPU and memory |

| 2 | Ground Plane | Provides EMI shielding and signal return path |

| 3-5 | High-Speed Routing | Routes signals between the GPU and VRAM |

| 6 | Power Plane | Distributes core and memory voltage |

| 7-8 | Additional Routing | Routes VRM feedback, sensors, and fan control |

| 9 | Secondary Power Layer | Distributes PCIe + auxiliary 12V and 5V paths |

| 10 | Backplane / Support | Adds structural rigidity and optional backplate attachment |

Each layer’s dielectric thickness, copper weight, and resin system are modeled using advanced 3D field solvers to ensure consistent impedance and minimal crosstalk.

For high-frequency PCB designs, this complex stack-up helps maintain consistent signal quality across all high-speed data channels.

4. PCB Materials and Manufacturing Optimization

Choosing the right materials is crucial for determining the electrical and thermal performance of the PCB video card.

High-Performance Laminates

High-performance laminates are essential to achieving the required signal integrity at high speeds and reliable heat management:

- Panasonic Megtron 6/7 - Ideal for 56-112 Gbps GPU interfaces with low-loss (Df ≤ 0.003).

- Isola Tachyon 100G - Ultra-low Df for high-speed PAM4 signaling.

- Rogers RO4350B - Hybrid dielectric suitable for RF and mixed-signal GPU applications.

- FR-4 High Tg (170°C+) - Cost-effective for mid-range GPUs, suitable for standard PCB manufacturing.

Copper and Surface Finishes

Copper weights of 1 oz-3 oz balance current capacity with heat conduction. Surface finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) improve solderability and oxidation resistance in mass production.

For heavy copper PCBs, especially where high current paths are required, thicker copper layers (up to 6 oz) are used to optimize both current handling and thermal dissipation.

PCB Fabrication Process

- Lamination & Drilling - Layers of copper and prepreg are pressed, and vias are drilled.

- Plating & Etching - Circuits are patterned through photolithography.

- Solder Mask & Silkscreen - Protection and component labeling.

- Surface Finish Application - ENIG or OSP is applied.

- Electrical Testing (E-test) - Verifies continuity and absence of shorts.

After fabrication, SMT assembly mounts the GPU, VRMs, capacitors, and interface modules with micron-level precision.

5. Impact of PCB Design on GPU Performance

The PCB video card is not just a passive carrier - it is a performance enabler.

A well-designed PCB has a direct impact on:

Clock Stability and Overclocking

Superior signal integrity allows GPUs to reach and sustain higher boost clocks without timing errors or instability, benefiting gaming and AI computations.

Power Efficiency and Noise

Optimized power plane design ensures efficient energy delivery, reducing heat generation and minimizing coil whine during high-performance tasks.

Thermal Balance

Thick copper PCB layers and thermal vias spread heat more evenly, keeping GPU temperatures stable even under prolonged usage.

Mechanical Reliability

Thicker PCBs (1.6-2.2 mm) with reinforced mounting zones reduce flexing under heavy coolers, enhancing the lifespan of the video card.

Request a PCB Manufacturing Quote

Looking to design or manufacture advanced multilayer PCB video cards for high-performance GPU systems? Partner with an experienced high-speed PCB manufacturer who understands impedance control, VRM thermal balance, and material science.

👉 Request a PCB manufacturing quote and get engineering-backed support from prototype to mass production.

Conclusion

A GPU’s true power doesn’t just come from its silicon - it comes from the PCB video card that connects, powers, and stabilizes it. From controlled impedance traces and copper-heavy planes to advanced laminates like Megtron 7 and Tachyon 100G, the PCB defines every aspect of the GPU's performance.

Well-designed PCBs ensure:

- Higher, more stable GPU clock speeds

- Efficient power delivery with minimal ripple

- Effective heat dissipation and long-term durability

In short, the PCB video card is the backbone of modern GPU innovation - an invisible yet essential component that turns theoretical processing power into real-world performance.