A purple PCB is a printed circuit board whose solder mask is tinted purple instead of the more traditional green. At first glance this looks like a purely cosmetic choice, but in professional hardware design the mask color can influence inspection quality, branding, process control, and even signal performance when the stack-up and materials are chosen correctly.

This article explains what purple solder masks are made of, how they behave electrically and optically, where they are used, and what engineers should consider when specifying a purple PCB in a professional design.

1. Solder Mask Basics and Color Options

On any modern PCB, the solder mask is a thin polymer layer laminated over the copper circuitry. Regardless of color, it has several critical functions:

- Electrical insulation between closely spaced tracks, pads, and planes

- Protection of copper from oxidation, chemical attack, and mechanical abrasion

- Solder definition, ensuring solder only wets exposed pads during reflow or wave soldering

- Support for fine-pitch assembly, preventing solder bridges on dense IC footprints

- Improved cleanliness, reducing ionic contamination and moisture absorption

Historically, green solder mask became the de-facto standard because early epoxy formulations offered high contrast, good process latitude, and low cost. Over time, other standard colors emerged-red, blue, black, white, and yellow-primarily for product differentiation or readability on specific assemblies.

Purple belongs to a newer generation of custom and brand-oriented colors. With digital imaging, improved pigments, and tighter process control, manufacturers can offer purple while still meeting IPC requirements for insulation resistance, thickness, and adhesion.

At HILPCB, solder mask color is treated as part of the overall stack-up strategy rather than a simple cosmetic option. Beyond purple, engineers can choose classic green boards such as Green FR4 PCB, high-reflectivity White FR4 PCB for LED products, branding-oriented Blue FR4 PCB, or optical-control Black FR4 PCB, as well as other custom solder mask colors tuned to each project’s visual and technical requirements.

In other words, HILPCB can customize PCB solder mask colors, not only purple, and help you select the most suitable color-material combination for your application.

2. Why Engineers Specify a Purple Solder Mask

Choosing purple is not just about looking different. When properly qualified, purple solder mask can offer a mix of visual, process, and technical advantages.

2.1 Branding, UX, and Product Identity

- Distinctive board color helps differentiate your hardware from competitors.

- Startups and consumer brands often use purple PCBs as a visual signature in teardowns and marketing material.

- Consistent color across multiple product generations reinforces brand recognition.

2.2 Optical Contrast and Inspectability

- Purple provides strong contrast against bare copper, ENIG, or immersion tin finishes and the pale FR-4 substrate.

- Silkscreen and laser marking in white or black stand out sharply on purple, aiding manual debug and rework.

- Many AOI (automated optical inspection) systems can achieve higher defect-detection sensitivity once lighting and thresholds are tuned for the purple hue.

2.3 Process Monitoring and Mask Uniformity

- Subtle shade variation is easier to see on purple than on darker green or black masks.

- Coating defects-such as under-cured areas, thin regions over sharp corners, or overspray-are easier to spot during visual inspection.

- This visual feedback encourages tighter process control on mask application, exposure, and curing.

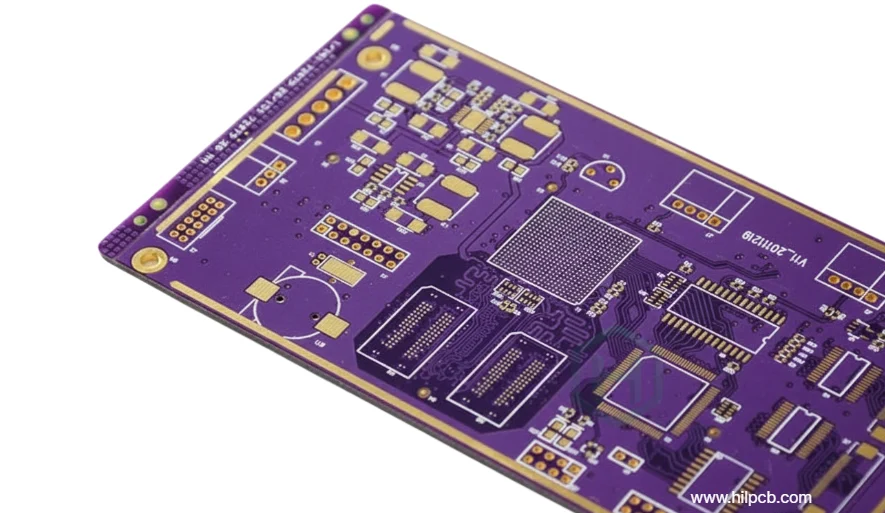

2.4 Support for High-Speed and RF Designs

The color itself does not change the dielectric constant, but the mask formulation and thickness do matter:

- Many purple masks are available as high-resolution, low-loss LPI (liquid photo-imageable) formulations.

- With correct thickness control, they contribute minimal additional loss in high-speed or RF structures such as microstrip and coplanar waveguides.

- For designs in the GHz range, specifying the mask family and target thickness in the fabrication notes is more important than the color name alone.

2.5 Lead-Free and High-Temperature Assembly

Modern purple masks are formulated to handle:

- Lead-free reflow profiles up to 260-270 °C peak

- Multiple reflow cycles for double-sided assembly

- Reduced yellowing and discoloration compared with older green formulations when exposed to repeated thermal cycling

3. Where Purple PCBs Are Used

Purple PCBs appear across a wide range of sectors where appearance and performance both matter.

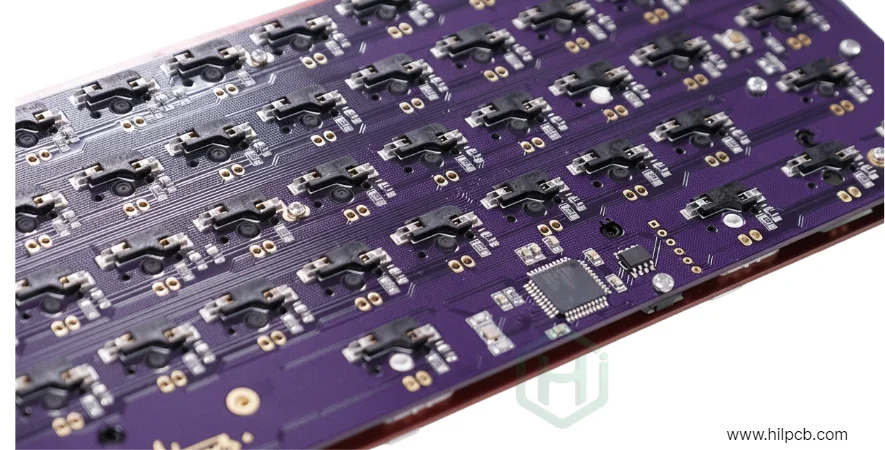

3.1 Consumer and Prosumer Electronics

- High-end keyboards, audio gear, synthesizers, and gaming peripherals

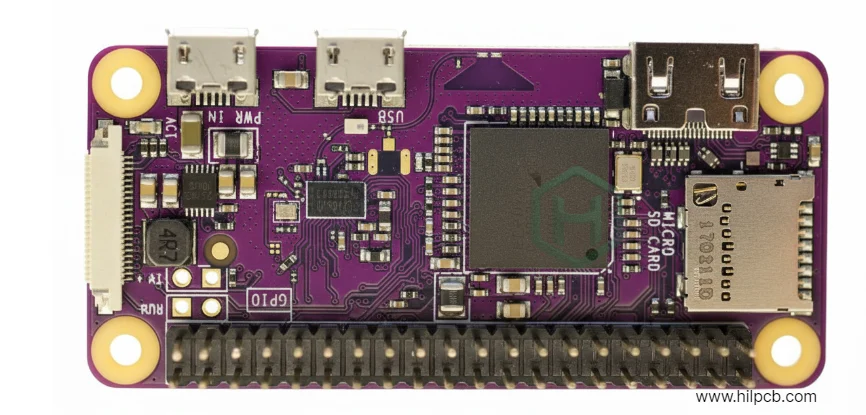

- Maker-focused development boards and open-hardware projects

- Smart home products where PCB visibility is part of the industrial design

(For a concrete example in consumer hardware, see HILPCB’s guide on Gaming Keyboard PCB.)

3.2 Automotive and Mobility Electronics

- Infotainment and instrument cluster modules

- Interior lighting controllers and ambient-light PCBs

- Specialty aftermarket ECUs and racing electronics where branding is important

3.3 Medical and Laboratory Equipment

- Compact patient monitoring devices

- Wearable medical sensors and patch-type electronics

- Diagnostic instrumentation where board contrast and trace visibility help during servicing

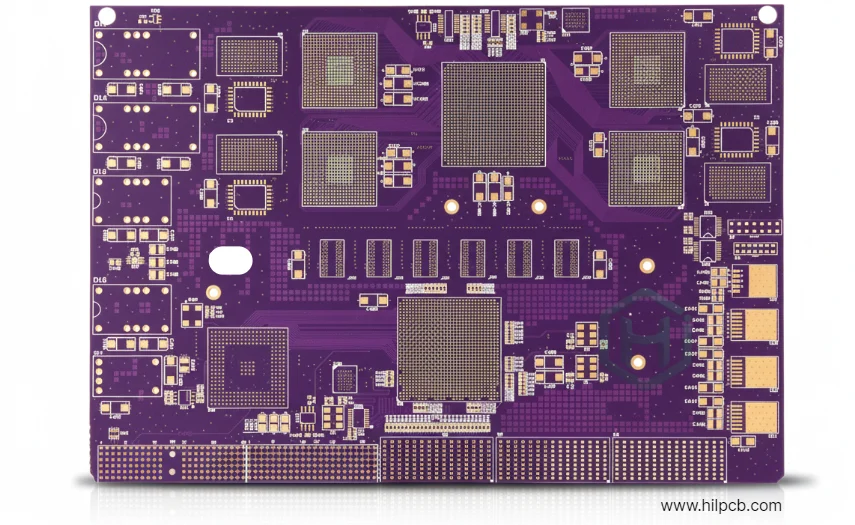

3.4 Aerospace, Industrial, and Test Systems

- Compact avionics, drones, and robotics controllers

- Industrial sensors, condition-monitoring modules, and edge controllers

- Test and measurement instruments that require excellent AOI performance and clear labeling

For mission-critical sectors such as aerospace and defense, HILPCB also offers dedicated outgassing-control and high-reliability PCB solutions, as detailed in its aerospace outgassing control PCB guide.

3.5 IoT Nodes and Networking

- Smart building controllers, access points, and small gateway devices

- Sensor nodes where compact multi-layer PCBs must remain inspectable after conformal coating

4. How Purple Solder Masks Are Manufactured

There are several practical routes to achieving a purple appearance on a PCB. Each has different implications for thickness, registration, and cost.

4.1 Pigmented Photo-Imageable Solder Mask

This is the most common method for professional fabrication:

- A standard LPI solder mask resin is blended with purple pigments at a controlled concentration.

- The mask is coated (spray, curtain-coat, or screen), dried, and photo-imaged through a film or direct-imaging system.

- Unexposed areas are developed away, leaving openings on pads and test points.

- The mask is thermally or UV-cured to reach final hardness and electrical performance.

Key points:

- Adding pigment can increase the optical density, sometimes requiring a slightly greater nominal thickness to achieve full coverage.

- When properly formulated, electrical insulation and surface insulation resistance remain fully compliant with IPC-SM-840.

4.2 Digital / Inkjet Solder Mask

Some advanced manufacturers use inkjet-applied solder mask:

- A clear or lightly tinted base mask is first applied.

- Purple mask is then deposited digitally in fine patterns.

- This method supports highly localized thickness control and is well-suited for prototypes and low-volume runs.

4.3 Base Mask with Purple Legend or Overprint

For cosmetic builds where only certain zones must appear purple:

- A neutral mask (for example, white) is applied and cured.

- A purple overprint or legend ink is printed in selected regions.

This does not replace the solder mask electrically; it mainly enhances visuals. Engineers should ensure only qualified materials are used where solderability or insulation are still required.

For LED and lighting projects that rely heavily on solder mask color and reflectivity, you can also refer to HILPCB’s article on LED PCB manufacturing, which explains how white and colored masks are tuned for optical performance.

5. Design Guidelines for Purple PCBs

Specifying a purple mask does not radically change PCB design rules, but there are important details to capture in fabrication notes and DFM checks.

5.1 Solder Mask Thickness and Clearances

- Verify the manufacturer’s nominal and minimum mask thickness for the chosen purple formulation.

- Adjust design rules if necessary for:

- Minimum solder mask dam width between fine-pitch pads

- Clearance around BGA pads and via-in-pad structures

- For high-speed work, include mask thickness assumptions in impedance calculations.

When you are dealing with complex multilayer and HDI stack-ups, HILPCB’s multilayer PCB manufacturing and high-speed PCB pages outline how stack-up modeling and coupon verification are handled in production.

5.2 Silkscreen and Component Marking Contrast

- On purple, white silkscreen offers excellent visibility for reference designators and polarity marks.

- Very dark components with black epoxy or dark laser marks may require enlarged text or additional polarity indicators.

- When using laser marking, verify that the mark contrast remains readable on the purple background.

5.3 AOI and Test Optimization

- Inform the fabrication partner that AOI will be used and that the mask color is purple.

- AOI cameras may need different illumination angles or thresholds versus standard green.

- Ensure bare-board test pads remain fully exposed, without residual pigment encroachment.

5.4 Stack-Up and Signal-Integrity Considerations

- For multi-gigabit links, coordinate mask data with the fabricator:

- Dielectric constant (Dk) and dissipation factor (Df) of the core/prepreg

- Target mask thickness and coverage over controlled-impedance traces

- Keep high-speed differential pairs free from unnecessary mask openings that might disturb impedance, unless intentional (for example, exposed RF launch regions).

For a broader view of specifying stack-ups and finishes in China PCB production, see the HILPCB guide on PCB manufacturing.

5.5 Reliability and Environmental Requirements

- Confirm that the purple mask is RoHS and REACH compliant, with documented insulation resistance and ionic cleanliness.

- For harsh environments, verify compatibility with conformal coatings and cleaning agents.

- For flex and rigid-flex boards, ensure the mask used on flex sections maintains adhesion during repeated bending.

For applications with demanding thermal or environmental conditions, HILPCB also provides dedicated high thermal conductivity PCB and outgassing control PCB solutions that can be combined with custom solder mask colors.

6. Advantages and Limitations of Purple Solder Masks

6.1 Potential Advantages

- Distinctive appearance that supports strong product branding

- Excellent copper and silkscreen contrast for both manual and automated inspection

- Good compatibility with high-temperature, lead-free assembly processes

- Availability in advanced, low-loss LPI families suitable for RF and high-speed designs

- Color variations make it easier to spot coating defects and process drifts

6.2 Possible Limitations

- Slightly higher cost than mass-production green masks due to lower volume and tighter control

- Minor color variation between manufacturing batches or different suppliers

- If pigment loading is high, mask thickness may increase and require updated design rules for tight-pitch components

- For overprint-based approaches, registration between mask, legend, and copper must be tightly controlled

The net result is that purple solder mask is best used when both appearance and engineering performance matter, and when your PCB supplier has a well-documented process for the specific mask system.

7. Selecting a Manufacturer for Purple PCBs

When you plan to deploy purple boards in production, evaluation of fabrication partners should include color-specific questions:

- Ask for sample panels or cross-sections showing their purple mask thickness, coverage, and adhesion.

- Review documentation for compliance with IPC-SM-840 (or equivalent) and any internal qualification testing.

- Confirm their minimum design rules for solder mask dams, registration, and silkscreen on the purple process.

- Discuss stack-up control for high-speed projects, including how mask thickness is modeled in impedance calculations.

- For applications with strict visual requirements, define an acceptable color range using printed samples or color codes.

- Start with a pilot build or prototype batch to validate assembly yield, AOI performance, and long-term reliability.

If you are still comparing suppliers, HILPCB’s overviews of PCB circuit board manufacturing and full PCB services explain how in-house fabrication, assembly, and engineering support are integrated from prototype to mass production.

FAQ

Q1: Does a purple solder mask change the electrical performance of a PCB?

A: Color alone does not determine electrical behavior. What matters is the mask formulation and thickness. When the purple mask is a qualified LPI system that meets IPC-SM-840, insulation resistance, leakage current, and breakdown voltage are comparable to those of green masks.

Q2: Will pigmented purple masks always be thicker than green masks?

A: In many processes, pigment loading does increase the nominal thickness by a few micrometers, but this is usually within IPC limits. Ask your fabricator for the actual thickness range and adjust design rules for fine-pitch areas if necessary.

Q3: How consistent is the purple shade between different fabrication houses?

A: Some variation is inevitable because each manufacturer may use a different resin and pigment system. For brand-critical products, qualify a primary supplier and agree on sample boards that define the acceptable color window.

Q4: Can different solder mask colors be used on the same PCB?

A: Yes, but it depends on the process. Using overprint or digital mask techniques, specific regions can be tinted differently. This requires very accurate registration and is generally more expensive, so it is used mainly for special edition or showcase boards.

Q5: Does a purple mask significantly increase fabrication cost?

A: Expect a modest premium compared with standard green-often on the order of 10-15% for production volumes-due to specialized materials, extra setup, and lower overall demand. For small prototype batches, the cost increase may be slightly higher.

Q6: Are purple solder masks suitable for flexible or rigid-flex PCBs?

A: Yes, provided that the fabricator uses a flex-rated solder mask system or coverlay ink with purple pigmentation. Color rendition can differ slightly on polyimide compared with FR-4, so it is wise to request flex samples if visual consistency is important.

Q7: Is there any impact on rework or repair when using a purple mask?

A: In practice, rework is similar to other colors. Many technicians find that the high contrast between purple mask, copper pads, and silkscreen actually improves visibility when performing manual soldering, hot-air rework, or microscope inspection.