Chemical safety regulations determine market access, supply chain partnerships, and operational viability across global electronics manufacturing. When chemical substances trigger REACH authorization requirements, consequences include production disruptions and potential market exclusion. REACH compliance PCB manufacturing addresses these challenges through systematic chemical management, safety assessment, and supply chain transparency ensuring European market access.

HILPCB maintains comprehensive REACH compliance programs covering chemical registration, substance evaluation, and authorization procedures ensuring full regulatory compliance for European market access.

Advanced Chemical Safety Management for REACH Compliance PCB Manufacturing

REACH compliance PCB manufacturing requires sophisticated chemical management systems addressing registration, evaluation, authorization, and restriction requirements through comprehensive safety assessment and supply chain transparency.

1. Comprehensive Chemical Inventory and Registration Management

REACH compliance demands complete identification and assessment of all chemical substances used in PCB manufacturing, requiring systematic evaluation of safety profiles, exposure scenarios, and risk management measures. Our chemical management systems maintain comprehensive databases supporting customer REACH obligations and regulatory compliance.

2. Advanced Substance Evaluation and Risk Assessment

Chemical safety assessment requires sophisticated evaluation of substance properties, exposure pathways, and risk characterization ensuring safe use throughout PCB manufacturing and downstream applications. Multi-level risk management approaches implement engineering controls and procedures minimizing exposure risks while maintaining production efficiency.

3. Supply Chain Transparency and Communication Systems

REACH requires comprehensive communication throughout supply chains regarding chemical safety, use restrictions, and risk management measures. Our communication systems provide detailed substance information and regulatory status updates supporting customer compliance obligations.

4. Continuous Regulatory Monitoring and Adaptation

REACH represents evolving regulatory framework requiring continuous monitoring of candidate lists, authorization procedures, and restriction proposals. Our regulatory intelligence systems track developments with proactive assessment of potential impacts and adaptation strategies.

5. Documentation and Audit Support Systems

REACH compliance requires comprehensive documentation supporting regulatory submissions, customer declarations, and enforcement agency inspections. Our documentation systems maintain complete records with secure access controls and retention procedures supporting long-term compliance obligations.

Managing Complex Chemical Formulations in Advanced PCB Applications

Advanced PCB applications often require specialized chemical formulations presenting unique REACH compliance challenges requiring sophisticated safety assessment and risk management approaches.

Key chemical management considerations include:

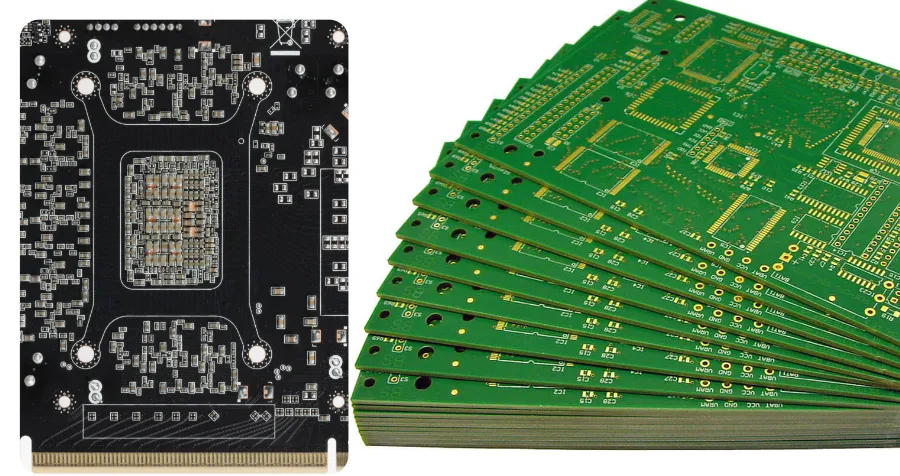

- High-frequency PCB material compliance ensuring specialized dielectric materials meet REACH requirements while maintaining electrical performance

- IC substrate PCB chemical safety addressing complex material systems for semiconductor packaging applications

- Advanced adhesive and encapsulant systems providing environmental protection while meeting chemical safety requirements for high-speed PCB applications

- Specialized surface treatment chemicals ensuring long-term reliability while maintaining REACH compliance

- Rigid-flex PCB material integration addressing diverse chemical systems for mechanical flexibility and electrical performance

- Thermal management material safety ensuring metal core PCB applications maintain chemical safety throughout high-temperature operations

Accelerating European Market Entry Through Proactive Compliance

Strategic Market Access Through Chemical Safety Excellence

European markets represent critical revenue opportunities that demand proactive REACH compliance rather than reactive regulatory response. Early compliance preparation enables rapid market entry while avoiding regulatory delays and supply chain disruptions that can postpone product launches and market opportunities.

Integrated Compliance and Product Development Workflow

Our REACH compliance process integrates seamlessly with product development:

- Early Chemical Assessment — identifying potential regulatory issues during design phases before they affect production schedules

- Alternative Substance Qualification — proactive evaluation of backup materials addressing potential restrictions or authorization requirements

- Regulatory Impact Analysis — comprehensive assessment of compliance requirements and business impact for informed decision-making

Risk Mitigation Through Systematic Planning

By implementing comprehensive chemical safety management early in product development cycles, we prevent regulatory surprises that could disrupt launch schedules or require costly design changes. This proactive approach reduces overall development risk while ensuring complete regulatory compliance.

Market Responsiveness and Competitive Advantage

Proactive REACH compliance enables organizations to:

- Enter European markets without regulatory delays or restrictions

- Respond rapidly to customer requirements for chemical safety documentation

- Maintain competitive advantage through reliable supply chain management and regulatory compliance

- Support customer sustainability goals and corporate responsibility commitments

Customization for Specialized European Market Applications

REACH compliance requirements vary significantly across different PCB applications and end-use sectors, requiring customized compliance approaches that address specific regulatory requirements, customer specifications, and technical performance needs within European market frameworks.

We support specialized REACH compliance requirements including HDI PCB applications with complex chemical systems, medical device applications requiring enhanced safety documentation, and automotive applications addressing sector-specific chemical safety requirements.

Advanced packaging applications often require specialized chemical formulations that demand individual REACH assessment and risk management approaches. Our chemical safety expertise addresses these unique requirements while maintaining optimal technical performance and manufacturing efficiency.

Comprehensive box build assembly services extend REACH compliance throughout complete system manufacturing, ensuring chemical safety consistency across all components and assembly processes while providing unified compliance documentation supporting customer European market access requirements.

Comprehensive Chemical Safety and Regulatory Support

Delivering REACH compliance requires integrated chemical safety management that addresses all aspects of European chemical regulations from substance registration through ongoing safety monitoring and regulatory adaptation. We provide end-to-end chemical safety support that encompasses regulatory intelligence, technical assessment, documentation management, and customer communication systems.

Our chemical safety expertise includes advanced toxicology assessment, environmental fate evaluation, and exposure modeling that supports comprehensive safety assessment for complex chemical formulations used in advanced PCB manufacturing. Regulatory intelligence systems provide early warning of potential restrictions or authorization requirements enabling proactive supply chain management and technical adaptation.

Quality management systems incorporate chemical safety considerations throughout manufacturing operations with systematic monitoring and continuous improvement programs that ensure ongoing compliance while optimizing technical performance and operational efficiency.

From initial chemical assessment through ongoing regulatory monitoring and customer support, our integrated approach ensures complete REACH compliance while maintaining superior PCB performance and reliability. Whether developing new products for European markets or adapting existing designs for REACH compliance, our chemical safety expertise provides the foundation for successful European market access and long-term regulatory compliance throughout evolving chemical safety requirements.