Every day, billions of people rely on remote controls to operate their televisions, air conditioners, garage doors, and smart home devices. Behind each button press lies a carefully designed Remote Control PCB that transforms user input into reliable wireless signals. From simple infrared TV remotes to sophisticated RF drone controllers, these compact circuit boards must deliver consistent performance while maintaining cost-effectiveness for mass production.

The modern remote control market spans diverse applications - entertainment systems requiring IR transmission, automotive key fobs using rolling code encryption, industrial equipment demanding long-range RF communication, and smart home devices integrating multiple wireless protocols. Each application presents unique engineering challenges that drive innovation in Remote Control PCB design and manufacturing.

Diverse Remote Control Technologies and Circuit Design

Television and entertainment Remote Control PCBs represent the largest market segment, typically utilizing infrared LED transmission with single-double-layer PCB construction for cost optimization. These designs integrate microcontrollers, IR LEDs, button matrix scanning, and battery management in compact layouts that fit ergonomic housing designs.

Air conditioner and HVAC Remote Control PCBs require more sophisticated functionality, incorporating LCD displays, temperature sensors, and complex control algorithms. These applications often employ multilayer PCB designs to accommodate additional circuitry while maintaining electromagnetic compatibility with sensitive display and sensor components.

Automotive key fobs and security Remote Control PCBs demand the highest reliability and security standards. These devices integrate encryption processors, rolling code generators, and multiple transmission frequencies within miniaturized packages. The critical nature of automotive applications requires rigorous testing and quality validation throughout the manufacturing process.

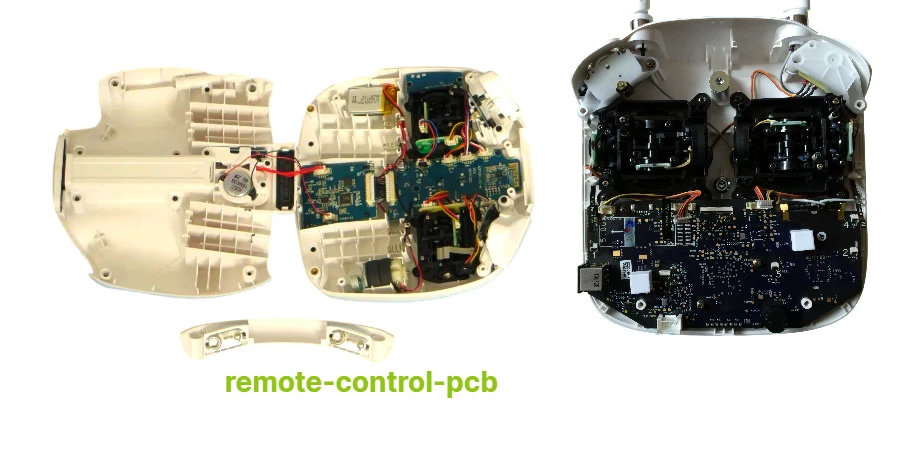

Drone and RC vehicle controllers represent the performance-oriented segment of Remote Control PCB applications. These sophisticated devices feature multiple analog sticks, digital switches, telemetry displays, and long-range RF transceivers. Professional drone remotes often incorporate GPS modules, video transmission capabilities, and programmable function buttons for complex flight operations.

Smart home and IoT Remote Control PCBs increasingly integrate WiFi, Bluetooth, and Zigbee connectivity alongside traditional IR functionality. These "universal" remotes can control multiple device types and often feature touchscreen interfaces, voice recognition, and smartphone app integration for enhanced user experiences.

Remote Control PCB Types and Applications

Consumer Electronics:

- TV and Set-Top Box Remotes: Simple infrared designs using single-double-layer PCB for cost optimization

- Air Conditioner Controllers: LCD-equipped remotes with temperature sensors and timer functions

- Audio System Remotes: Volume control, source selection, and digital audio processing

- Gaming Console Controllers: Wireless connectivity with haptic feedback integration

Automotive and Security:

- Car Key Fobs: Rolling code encryption and multiple frequency support

- Garage Door Openers: Long-range RF transmission with safety features

- Security System Controllers: Panic buttons, zone control, and two-way communication

- Gate and Barrier Controls: Industrial-grade reliability for commercial applications

Smart Home and IoT:

- Universal Smart Remotes: Multi-protocol support including WiFi, Bluetooth, and IR

- Voice-Enabled Controllers: Microphone integration and cloud connectivity

- Home Automation Hubs: Central control for lighting, climate, and security systems

Professional and Industrial:

- Drone and RC Controllers: High-precision analog controls with telemetry displays

- Industrial Machine Remotes: Ruggedized designs for harsh environments

- Medical Equipment Controllers: Sterile operation and regulatory compliance

- Presentation and Conference Remotes: Laser pointers and slide navigation

Power Management: Extending Battery Life

Battery performance directly impacts user satisfaction with Remote Control PCBs. Modern designs must balance functionality with ultra-low power consumption.

Sleep Mode Optimization: Advanced Remote Control PCBs implement multiple power states, consuming microamperes during standby while maintaining instant response to user input. Sophisticated wake-up circuits ensure immediate activation when buttons are pressed.

Efficient Wireless Communication: Different wireless protocols offer varying power consumption profiles. Infrared remains most efficient for line-of-sight applications, while Bluetooth Low Energy provides excellent battery life for smart home remotes requiring two-way communication.

Energy Harvesting Solutions: Premium Remote Control PCBs increasingly incorporate solar panels or kinetic energy harvesting. These designs utilize flex PCB technology for flexible solar cell integration and battery interconnections.

Smart Power Management: Intelligent circuits monitor usage patterns and automatically adjust power consumption. Features include automatic backlight dimming, transmission power adjustment based on distance, and predictive sleep scheduling.

Innovation Powering Today’s Advanced Remote Control Solutions

Modern remote controls are no longer simple transmitters—they have evolved into multifunctional hubs that combine multi-protocol wireless communication, intelligent sensing, and enhanced user interaction. At HILPCB, we don’t just follow these trends—we already design and manufacture Remote Control PCBs that deliver these advanced capabilities today. Our solutions empower clients to launch competitive products equipped with market-proven technologies that meet consumer expectations and stand out in a crowded marketplace.

Our designs support voice recognition and AI-driven interaction, enabling hands-free operation through cloud-based algorithms. Gesture recognition and motion control features—powered by accelerometers, gyroscopes, and sophisticated signal processing—add intuitive pointing, waving, and air-mouse capabilities that appeal to modern, tech-savvy users. To protect connected devices, our high-security PCB designs integrate hardware security modules (HSM), encrypted communication protocols, and secure boot processes, ensuring privacy and reliability for automotive, smart home, and industrial applications.

We also deliver premium user experiences with haptic feedback, achieved by integrating vibration motors and force sensors into Rigid-flex PCB designs. Sustainability is built into our processes, with lead-free soldering, halogen-free laminates, and recyclable components that meet global environmental regulations—helping our customers strengthen their brand image while ensuring compliance. These capabilities are not futuristic concepts—they are fully in production now, manufactured by HILPCB with the precision, quality, and speed that our clients trust.

Beyond Remote Controls – Why HILPCB is Your Complete PCB Manufacturing Partner

Remote Control PCBs are only one part of our broad manufacturing capabilities. HILPCB serves automotive, medical, industrial automation, consumer electronics, and telecommunications markets, providing cross-industry expertise that enhances every project we take on.

Our Key Advantages:

- Flexible Production – From 5-piece prototypes to millions of units annually.

- Proven Expertise – 15+ years of experience across diverse PCB technologies and applications.

- Quality Assurance – IPC-A-610 Class 3 standards and 99.2% first-pass yield rates.

- Global Supply Chain – Reliable sourcing and logistics for consistent component availability.

- Design Support – Engineering collaboration for manufacturability, cost control, and performance optimization.

Whether you need Remote Control PCBs, automotive electronics, medical device boards, or industrial control systems, HILPCB provides the precision manufacturing, quality validation, and on-time delivery that keeps your business competitive.

Frequently Asked Questions

Q: What types of Remote Control PCBs do you manufacture?

A: We manufacture the complete range of Remote Control PCBs including TV and entertainment remotes, air conditioner controllers, automotive key fobs, drone controllers, garage door openers, smart home devices, and industrial wireless controllers. Our capabilities span from simple IR transmitters to complex multi-protocol wireless systems.

Q: How do you optimize Remote Control PCBs for different applications?

A: Each application has unique requirements. TV remotes prioritize cost and simplicity, automotive remotes demand security and reliability, drone controllers need long-range performance, and smart remotes require multi-protocol integration. We optimize design, component selection, and manufacturing processes for each specific application.

Q: Can you handle both small prototypes and large production volumes?

A: Yes, our manufacturing capabilities scale from prototype quantities for product development to millions of units for consumer electronics. We provide design for manufacturability guidance to ensure smooth transition from prototype to high-volume production.

Q: What wireless technologies do you support in Remote Control PCBs?

A: We support all common wireless technologies including infrared (IR), 315MHz/433MHz RF, 2.4GHz proprietary protocols, Bluetooth, WiFi, Zigbee, and emerging technologies like matter/thread. Our designs can integrate multiple protocols within single remote control devices.