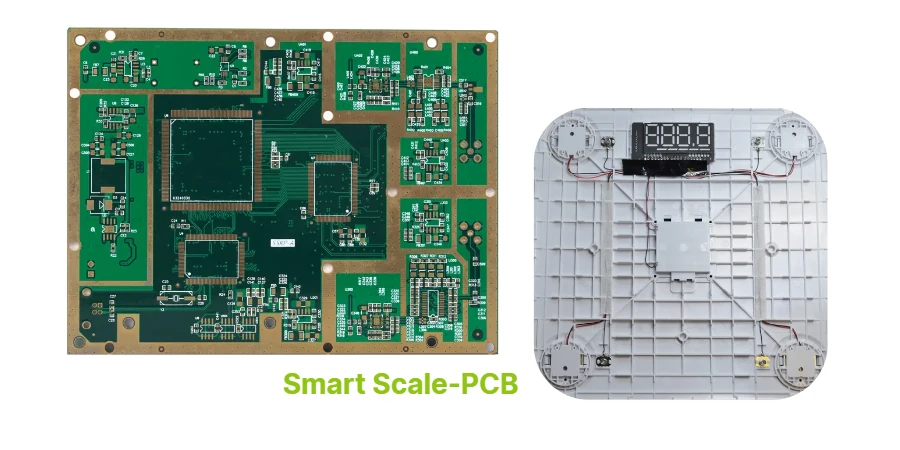

At HILPCB, we specialize in manufacturing and assembling high-precision Smart Scale PCBs for health monitoring devices. Our solutions cover everything from bioimpedance measurement circuits and load cell amplification boards to wireless modules and complete turnkey assembly. Designed for accuracy, stability, and user safety, our PCBs meet both consumer fitness and medical-grade requirements, ensuring reliable performance in weight measurement, body composition analysis, and connected wellness platforms.

Smart Scale PCB Architecture and Biomedical Sensing Integration

A modern Smart Scale PCB must integrate high-precision load cells, bioelectrical impedance analysis circuits, microcontroller systems, and wireless communication modules while maintaining medical-grade accuracy and user safety standards. The core architecture for Body Composition PCB applications includes:

- Ultra-precise load cell amplification circuits for Health Monitoring PCB weight measurement with 0.1lb/50g accuracy

- Multi-frequency bioelectrical impedance analysis (BIA) systems for BIA Scale PCB body fat, muscle mass, and water percentage detection

- Advanced analog-to-digital converters for Fitness Scale PCB high-resolution sensor data acquisition

- Connected Health PCB specific: Bluetooth Low Energy, WiFi modules, and secure data encryption protocols

- Microcontroller units with dedicated DSP capabilities for real-time body composition calculations

- Temperature compensation circuits for consistent measurements across environmental conditions

- User recognition algorithms and multi-profile memory storage systems

- FDA-compliant safety circuits for bioelectrical current limitation and user protection

Professional Connected Health PCB designs typically employ 2-8 layer multilayer PCB structures to accommodate complex analog signal paths, digital processing systems, and wireless communication circuits while maintaining strict electromagnetic compatibility for medical device applications. The challenge of Health Monitoring PCB design lies in achieving medical-grade measurement precision while supporting advanced connectivity features, requiring specialized FR4 PCB materials with enhanced dielectric stability and long-term reliability for bathroom environments.

Fitness Scale PCB systems increasingly integrate AI-powered health analytics and personalized wellness recommendations, enabling comprehensive body composition trends analysis and health goal tracking in sleek, user-friendly designs utilizing HDI PCB technology for maximum component integration density while maintaining measurement accuracy.

Advanced Manufacturing for Health Technology Devices

Our production capabilities are specifically optimized for the demanding requirements of Smart Scale PCB and Body Composition PCB manufacturing:

- Health Monitoring PCB: Medical-grade precision with controlled impedance design for bioelectrical safety and measurement accuracy

- BIA Scale PCB: Multi-frequency signal generation circuits with precise amplitude and phase control using single-double-layer PCB configurations for cost-effective basic fitness tracking models

- Fitness Scale PCB: Advanced sensor fusion algorithms integrating weight, impedance, and environmental compensation

- Connected Health PCB: Secure wireless protocols with end-to-end encryption for health data protection

- Smart Scale PCB: Power management systems optimized for battery life with ultra-low standby consumption

- Body Composition PCB: Clinical-grade calibration circuits ensuring consistent measurements across user demographics

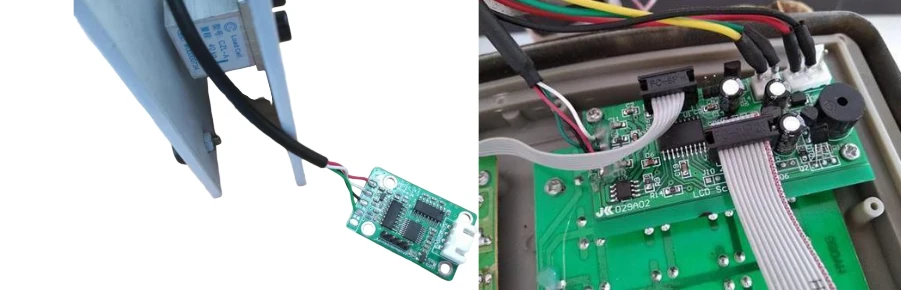

SMT assembly lines are configured for precision placement of sensitive analog components, integrating load cell amplifiers, bioimpedance generators, wireless modules, and safety circuits. Our turnkey assembly services for Smart Scale PCB include firmware programming, sensor calibration, medical device testing, and comprehensive validation including accuracy verification, safety compliance testing, and electromagnetic compatibility validation across temperature and humidity ranges.

Precision Sensing and Measurement Technology

Smart Scale PCB and Body Composition PCB designs require sophisticated analog front-end circuits to achieve medical-grade measurement accuracy while supporting advanced health monitoring features:

- Health Monitoring PCB: Ultra-low noise amplification for load cell signals with temperature drift compensation

- BIA Scale PCB: Multi-frequency excitation generators providing precise current control for bioelectrical impedance measurement using high-Tg PCB materials for enhanced thermal stability during continuous operation

- Fitness Scale PCB: Advanced signal processing algorithms for body composition calculation and user pattern recognition

- Connected Health PCB: Secure data logging with encrypted storage and HIPAA-compliant transmission protocols

- Smart Scale PCB: Adaptive measurement systems adjusting for user characteristics and environmental factors

- Machine learning integration for personalized health insights and predictive analytics

- Rigid-flex PCB interconnect solutions for load cell integration and platform assembly optimization

Body Composition PCB designs require precise frequency synthesis and harmonic control to achieve accurate bioelectrical measurements across diverse user populations while maintaining safety compliance with medical device regulations for electrical current exposure limits.

Comprehensive Health Technology Ecosystem

Beyond core Smart Scale PCB manufacturing, we provide integrated health monitoring technology solutions:

Advanced Sensing Integration:

- High-precision load cell modules for Health Monitoring PCB applications with temperature compensation and drift correction

- Multi-electrode bioimpedance measurement systems for comprehensive body composition analysis

- Environmental sensors for humidity, temperature, and barometric pressure compensation

- Heart rate detection through electrodermal sensing for advanced health metrics

Connectivity and Data Management:

- Bluetooth Low Energy modules for BIA Scale PCB smartphone app integration with low power consumption

- WiFi connectivity with cloud synchronization for family health tracking and medical provider access

- Secure data encryption modules ensuring HIPAA compliance and user privacy protection

- Integration with popular health platforms including Apple Health, Google Fit, and Fitbit ecosystems

User Experience Enhancement:

- High-resolution LCD displays with customizable health metric presentation

- Voice feedback systems for guided measurement and health coaching

- Multi-user recognition algorithms supporting family health tracking

- Pregnancy and athlete modes for specialized measurement accuracy

Why Choose HILPCB for Smart Scale PCB Manufacturing

Choosing HILPCB means partnering with a manufacturer who understands that smart scale performance depends on measurement accuracy, long-term reliability, and regulatory compliance. We offer ISO 13485-certified production, IPC-A-610 Class 3 quality standards, and specialized experience in biomedical electronics. From prototype to mass production, we handle component sourcing, precision assembly, and full functional testing—including accuracy calibration and safety verification—so your devices are ready for market launch with confidence.

Frequently Asked Questions

Q: What makes Smart Scale PCB design challenging?

A: Smart Scale PCB design requires balancing ultra-precise analog signal processing for bioelectrical measurements with medical-grade safety compliance. Key challenges include maintaining accurate bioimpedance measurement across diverse users while ensuring FDA-compliant current safety limits and wireless connectivity integration.

Q: How do you ensure measurement accuracy?

A: Our Smart Scale PCBs use advanced temperature compensation, humidity correction, and environmental sensor integration. Multi-point calibration systems and drift compensation algorithms ensure consistent accuracy across varying bathroom conditions.

Q: What certifications do your Smart Scale PCBs meet?

A: Our Smart Scale PCBs meet FDA Class II medical device standards, IEC 60601 electrical safety requirements, and ISO 13485 quality management. We provide full regulatory support for medical device certification.

Q: Can you handle both consumer and medical applications?

A: Yes. We produce Smart Scale PCBs from cost-effective consumer fitness scales to clinical-grade body composition analyzers, including telemedicine integration and remote patient monitoring capabilities.