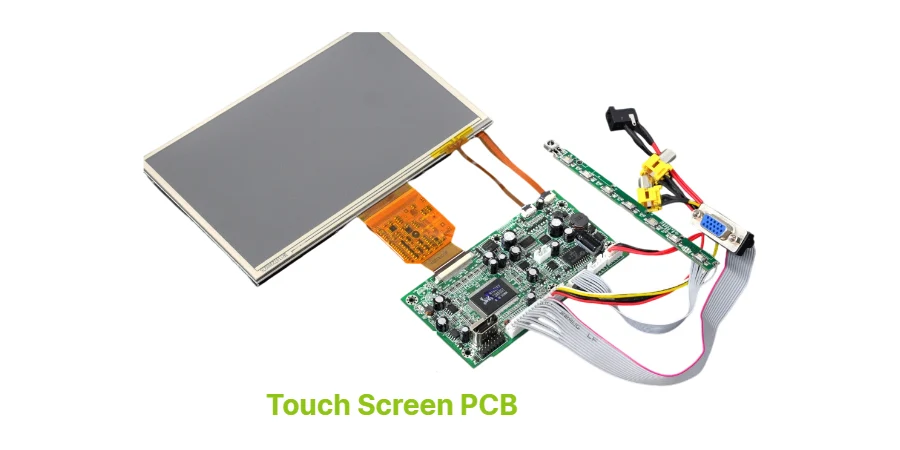

Highleap PCB Factory (HILPCB) is a comprehensive PCB manufacturing and assembly partner in China, delivering high-quality solutions for a diverse range of industries and products—including Touch Screen PCB and related technologies. Our factory supports both capacitive and resistive touch requirements, but our core capability is the ability to produce nearly any PCB type and provide tailored turnkey assembly, from prototypes to high-volume production.

Core Principles of Touch Screen PCB Technology

Touch Screen PCBs are the foundation of modern interactive devices, responsible for sensing, processing, and communicating touch inputs. The most popular approaches are capacitive and resistive touch PCBs:

- Capacitive Touch Screen PCB: Utilizes transparent conductive layers (such as ITO) and dedicated controller ICs to detect finger proximity and movement. Ideal for smartphones, tablets, and automotive displays due to multi-touch capability, high sensitivity, and long lifespan.

- Resistive Touch Screen PCB: Employs layered structures with flexible substrates and spacer dots to register pressure-based input. Common in industrial equipment and ATM interfaces for their durability and operation with gloves or styluses.

Key design factors include sensor pattern layout, signal routing, EMI shielding, grounding, and controller integration. Touch screen PCB controller boards often require high-speed multilayer PCB designs, impedance control, and low-noise analog front ends to ensure reliable touch detection.

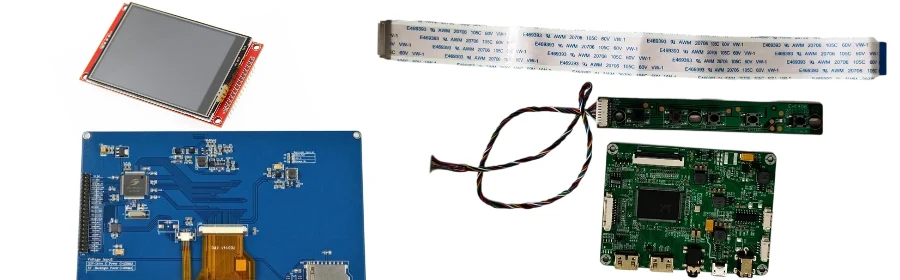

Peripheral products such as touch screen flex PCBs, touch IC substrate PCBs, and touch screen controller PCB modules are frequently customized to match specific display sizes, form factors, and connector arrangements.

Advanced Materials and Manufacturing for Touch Screen PCBs

High-performance Touch Screen PCBs depend on specialized materials and precise process control:

- Transparent Conductors: Indium tin oxide (ITO), silver nanowire, and graphene films are used for the touch sensor layers, enabling invisible circuits over displays.

- Substrates: FR-4 PCB is standard for controller boards; flex PCB and rigid-flex PCB are preferred for compact/mobile touch screen PCB designs.

- Surface Finishes: ENIG, OSP, or immersion silver finishes provide robust solderability for fine-pitch ICs and connectors.

- EMI Shielding and Grounding: Essential to minimize interference from display driver circuits and achieve stable touch response.

Our touch screen PCB manufacturing supports advanced patterning via laser direct imaging, precision etching, and cleanroom assembly for defect-free sensor circuits. We offer custom stackups for slim devices, high-Tg materials for automotive, and robust environmental protection for medical/industrial panels.

Assembly and Integration of Touch Screen PCB Solutions

Touch Screen PCB assembly begins with precise mounting of touch controller ICs, passive components, and connectors, followed by integration with glass or plastic sensor panels. High-speed SMT assembly ensures accurate placement of controller boards, while advanced reflow soldering guarantees reliable electrical connections. For ultra-thin, bezel-less displays, COF (Chip-on-Flex) and IC substrate PCB technologies are employed to achieve minimal thickness without compromising performance.

The assembly process also includes bonding and lamination steps, where touch sensor layers are optically bonded to glass or plastic substrates. This not only enhances durability but also improves visual clarity by reducing light reflection and air gaps. The bonding methods are carefully selected to meet the mechanical and optical requirements of each application, ensuring long-lasting and consistent touch performance.

To guarantee optimal functionality, all assemblies undergo rigorous testing procedures. These include AOI inspection for solder quality, functional testing to verify performance, and precise touchscreen calibration for responsiveness and accuracy. Our turnkey assembly service covers the complete process—from sourcing peripheral modules like flex tails, controller boards, and custom connectors to final assembly and testing—delivering ready-to-use solutions tailored to your specifications.

Design Strategies for Reliable Touch Screen PCB Performance

Optimizing Touch Screen PCB design is critical for touch accuracy, EMC compliance, and manufacturability:

- Sensor Pattern Optimization: Custom electrode shapes and spacing, tailored to display resolution and input requirements.

- Impedance Control: Essential for signal integrity in high-speed touch controller boards; use high-speed PCB stackups and matched trace pairs.

- EMC/EMI Mitigation: Strategic placement of ground shields, ferrite beads, and guard traces to reduce noise from display drivers, power circuits, or wireless modules.

- Mechanical Integration: Design for robust mounting, drop resistance, and proper alignment with display panels, especially in automotive and outdoor applications.

- Firmware and Calibration: Custom firmware for touch controller ICs, supporting gesture recognition, palm rejection, and multi-touch; factory calibration for consistent user experience.

We support design-for-manufacturing (DFM) reviews, simulation, and prototyping to ensure your touch screen PCB moves smoothly from concept to mass production.

Why partner with HILPCB for your Touch Screen PCB needs?

- Expertise in PCB for Touch Applications: Specialist in boards for capacitive, resistive, and hybrid touch systems, tailored for controller and sensor integration.

- Material Flexibility: Wide choice of substrates, including FR-4, high-Tg, and flex for unique layouts and reliability.

- Precision Assembly: Fine-pitch SMT, impedance control, and DFM engineering to avoid common touch PCB pitfalls.

- Quality Assurance: IPC-A-600 and ISO 9001 compliance, rigorous electrical and functional testing, full traceability.

- Scalable Production: From prototypes to mass production, quick turnaround and flexible batch sizes.

- Transparent Communication: Engineering feedback, online Gerber viewer, and responsive support throughout your project.

We do not manufacture complete touch screen modules or displays; our expertise is in delivering the reliable, high-performance PCBs that form the backbone of these systems, enabling successful integration by your design and module teams.

Frequently Asked Questions

1. What’s the difference between capacitive and resistive touch screen PCBs?

Capacitive touch screen PCBs detect changes in electrical charge and support multi-touch, ideal for smartphones and tablets. Resistive types respond to pressure and work with gloves or styluses, common in industrial and ATM applications.

2. How do I choose the right Touch Screen PCB material?

For controller boards, FR-4 is standard; for sensor layers, transparent conductors like ITO or silver nanowire are used. Flex and rigid-flex PCBs are preferred for space-saving designs and curved panels.

3. What quality standards apply to Touch Screen PCB manufacturing?

We comply with IPC-A-600, ISO 9001, and automotive/medical standards on request. All boards undergo AOI and functional testing for sensitivity, accuracy, and durability.

4. Can you supply Touch Screen PCB peripheral products?

Yes, we offer controller boards, flex tails, custom connectors, bonding frames, and complete touch screen PCB modules for various display sizes and technologies.

5. What’s the typical lead time for Touch Screen PCB prototypes and volume orders?

Prototypes are usually delivered in 7-10 days. Volume orders depend on complexity, ranging from 2-4 weeks. Expedited service is available for urgent projects.

6. How do you ensure EMC/EMI compliance in Touch Screen PCB designs?

We use shield layers, optimized ground planes, and layout simulation to minimize interference. DFM and EMC testing are part of our engineering support.

7. What assembly options are available for Touch Screen PCB solutions?

Options include SMT, COF, and turnkey assembly with full functional and calibration testing. We handle integration of touch screen PCB peripherals for ready-to-use modules.

If you’re looking for a reliable partner in Touch Screen PCB manufacturing and assembly, contact Highleap PCB Factory for expert engineering, rapid prototyping, and high-quality production tailored to your specific needs.