Modern missile systems demand unprecedented precision and reliability from their electronic components. As an experienced aerospace PCB manufacturer, HILPCB delivers cutting-edge missile guidance circuit board solutions that meet the most stringent military specifications. Our ITAR-compliant PCB manufacturing processes ensure superior performance in extreme environments, supporting frequencies up to 40 GHz while maintaining MIL-PRF-31032 compliance for mission-critical defense applications.

Missile PCB Technology and High-Frequency Signal Processing

Missile guidance systems rely on real-time data processing and signal transmission to hit targets with pinpoint accuracy. PCBs in missile guidance systems handle high-frequency signals, often above 1 GHz, to communicate with sensors, control units, and navigation systems.

Core Missile PCB Components:

- Guidance Electronics: Advanced inertial navigation systems (INS) and GPS receivers requiring ultra-precise signal processing

- RF Communication Systems: High-frequency transceivers operating at frequencies up to 40 GHz for telemetry and command links

- Sensor Interface Circuits: Multi-channel analog-to-digital converters processing data from accelerometers, gyroscopes, and magnetometers

- Power Management Systems: Efficient DC-DC converters optimized for space-constrained environments

These missile guidance circuit boards must support high-frequency signals up to 40 GHz and handle complex data from multiple sources simultaneously. The fundamental challenge involves maintaining signal integrity while operating in harsh environmental conditions including extreme temperatures from -55°C to 125°C and intense vibrations up to 20G acceleration.

Our RF circuit board for missile applications expertise ensures optimal signal transmission with specialized materials featuring low dissipation factors (Df < 0.005) and controlled impedance tolerances within ±5%. These high-frequency PCB solutions are essential for maintaining communication integrity in mission-critical scenarios.

Military Standards and MIL-Spec Compliance

Military circuit boards must adhere to specific standards to ensure reliability in missile applications. MIL-PRF-31032 serves as the primary standard for defense electronics manufacturing, specifying design rules for military-grade PCB solutions.

Essential Military Standards:

- MIL-PRF-31032: Primary standard covering all PCB types with comprehensive performance requirements and ongoing audit requirements

- IPC-6012 Class 3/3A: High-reliability specifications with stricter defect criteria than commercial standards

- AS9100: Aerospace quality management system ensuring consistent manufacturing processes

- MIL-STD-461: Electromagnetic compatibility requirements for defense systems

Critical Compliance Requirements:

- Electrical testing with continuity less than 10Ω and isolation greater than 10mΩ

- Monthly thermal stress testing on cross-sections

- Ionic contamination limits of 1.56 micrograms/square centimeter

- Copper plating standards meeting minimum elongation and tensile strength requirements

Our multilayer PCB manufacturing follows MIL-PRF-31032 guidelines with ongoing audits, technical review boards, and DLA-certified laboratory testing to maintain approved supplier status.

Advanced Materials for Extreme Environments

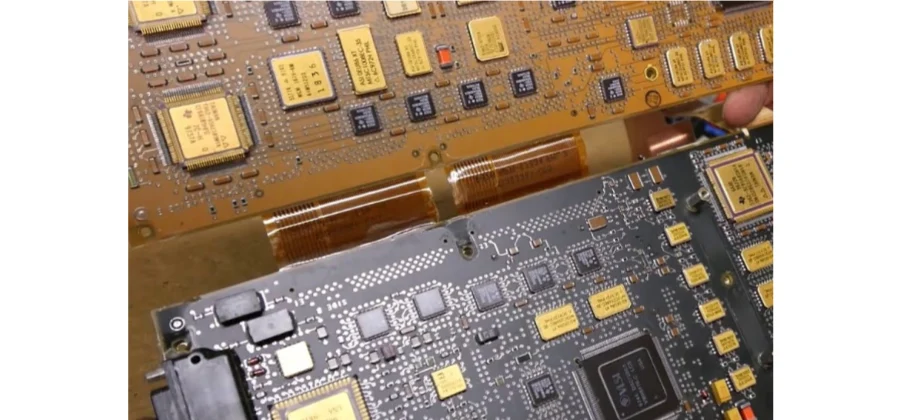

Missile PCBs must operate reliably in extreme conditions that would destroy conventional electronics. Materials must account for thermal expansion, which can shift traces by up to 10 micrometers per degree Celsius.

High-Performance Material Solutions:

- Rogers High-Frequency Laminates: Stable dielectric properties with Df values below 0.001 for frequencies up to 40 GHz

- Polyimide Flexible Substrates: Temperature range from -269°C to +400°C with exceptional chemical resistance

- Ceramic Substrates: Ultra-low expansion materials for precision oscillator circuits with thermal conductivity up to 170 W/mK

- PTFE-Based Composites: Low-loss dielectric materials essential for microwave applications

Environmental Resistance Requirements:

- Temperature cycling from -55°C to +125°C with minimal performance degradation

- Shock and vibration resistance up to 20G acceleration per MIL-STD-810

- Humidity and salt spray corrosion resistance meeting MIL-STD-202

- Chemical resistance against fuel vapors, hydraulic fluids, and cleaning solvents

Our ceramic PCB technology provides exceptional thermal conductivity and dimensional stability for high-power missile guidance applications.

Precision Manufacturing and Quality Control

Manufacturing missile guidance circuit boards requires exceptional precision and quality control. Military-grade PCBs must be designed from scratch following IPC 6012 class 3/A specifications with stringent fabrication processes.

Advanced Manufacturing Capabilities:

- HDI Technology: Microvias as small as 0.004 inches for maximum miniaturization

- Controlled Impedance: Precision matching within ±5% tolerance for critical RF paths

- Sequential Lamination: Multi-stage processes for complex layer stack-ups with mixed materials

- Via-in-Pad Technology: Maximum component density in space-constrained environments

Comprehensive Testing Protocol:

- 100% electrical testing with flying probe and bed-of-nails systems

- Cross-sectional analysis for via quality and layer registration

- Thermal stress testing validating long-term reliability

- RF performance verification using network analyzers

Our SMT assembly services include specialized placement for miniature BGAs and CSPs commonly used in missile electronics.

Why Choose HILPCB for Missile PCB Manufacturing

As a leading aerospace PCB manufacturer, HILPCB understands the critical importance of mission success, regulatory compliance, and operational security. Our comprehensive capabilities support the most demanding military applications with full ITAR compliance.

Our Defense Industry Advantages:

- Military Certifications: MIL-PRF-31032, AS9100, and IPC-6012 Class 3/3A certified processes

- ITAR-Compliant PCB Manufacturing: Registered defense contractor with secure facilities and vetted personnel

- Advanced Testing: Complete RF characterization, thermal cycling, and accelerated life testing

- Supply Chain Security: Qualified vendor networks with component authentication and traceability

We integrate Automated Optical Inspection (AOI), X-ray inspection, and environmental stress screening to ensure complete reliability. Our facility applies rigorous quality control throughout manufacturing, from prototype development to large-volume assembly production.

Specialized Support Services:

- Design engineering assistance for electromagnetic compatibility and thermal management

- Obsolescence management for extended program lifecycles

- Configuration control meeting DoD documentation requirements

- Turnkey assembly supporting complete system integration

Emerging Trends in Missile PCB Technology

The future of missile guidance systems is being shaped by revolutionary advances in AI, quantum technologies, and advanced materials. These emerging trends require continuous evolution in PCB design and manufacturing.

AI-Driven Sensor Fusion: Modern systems incorporate AI processing units requiring high-bandwidth memory interfaces, specialized cooling solutions, and ultra-low latency interconnects between sensors and processors.

Quantum-Enhanced Navigation: Quantum inertial measurement units promise unprecedented accuracy, requiring ultra-stable power supplies, cryogenic electronics, and precision timing distribution with femtosecond accuracy.

Advanced Security: Next-generation systems demand post-quantum cryptography hardware, true random number generators, and side-channel attack resistant designs for secure communications.

Emerging Materials: Graphene-enhanced conductors, metamaterial antennas, self-healing polymers, and 3D printed electronics enable new capabilities while improving reliability and performance.

Need a defense-grade PCB for your next missile guidance project? Our ITAR-compliant PCB manufacturing team is ready to support your mission-critical requirements.

Missile PCB Design and Manufacturing FAQ

What frequency ranges do missile PCBs typically operate at?

Missile PCBs handle frequencies from DC to 40 GHz, with most guidance systems operating between 1-20 GHz. Critical applications include L-band GPS (1.5 GHz), S-band telemetry (2-4 GHz), and X-band radar (8-12 GHz).

How do environmental conditions affect missile PCB design?

Missile environments present extreme challenges including temperatures from -55°C to +125°C, shock loads up to 20G, and intense electromagnetic fields. Designs must use materials with matched thermal expansion coefficients and robust EMI shielding.

What are the key differences between MIL-PRF-31032 and IPC-6012 Class 3?

MIL-PRF-31032 requires more stringent qualification including ongoing audits, technical review boards, and DLA-certified testing. It has stricter defect criteria and material approval processes compared to IPC-6012 Class 3.

What testing is required for missile PCB qualification?

Comprehensive testing includes electrical verification, thermal cycling, vibration testing, EMC compliance, and accelerated life testing. Military standards require statistical sampling and periodic re-qualification.

How does HILPCB ensure supply chain security?

We maintain ITAR compliance with vetted suppliers, component authentication programs, and secure facilities. Our quality system includes supplier audits, material traceability, and anti-counterfeiting measures meeting DoD requirements.

Can HILPCB support both development and production phases?

Yes, our capabilities span rapid prototyping for R&D programs through high-volume production with design support, qualification testing, and scalable manufacturing including configuration control and obsolescence management.