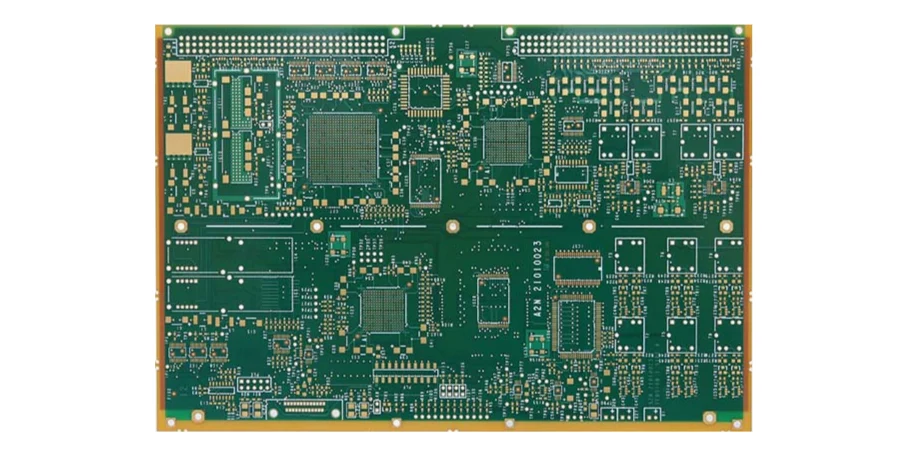

At HILPCB, we specialize in manufacturing high-precision PCBs for a wide range of applications, including medical imaging systems, automotive electronics, telecommunications, and more. Our expertise spans from flexible and rigid-flex PCBs to high-frequency, multilayer, and high-Tg PCBs, ensuring exceptional performance and reliability across all industries. Whether it’s for multi-channel RF coil arrays, gradient control circuits, or complex automotive ECUs, our ISO 13485-certified manufacturing processes guarantee the highest safety and quality standards for all types of PCB applications.

MRI PCB Technology and Signal Processing Fundamentals

Magnetic Resonance Imaging (MRI) systems rely on sophisticated printed circuit board technology to process radiofrequency signals at precise Larmor frequencies. PCBs for Magnetic Resonance Imaging (MRI) equipment have high demands for high-speed signal processing, signal integrity, and controlled stack-ups. The fundamental principle involves managing RF signals that vary with magnetic field strength: 63.9 MHz at 1.5T, 127.8 MHz at 3T, and 297.2 MHz at 7T systems.

Core MRI PCB Components:

- RF Coil Elements: The flexible multi-layer part contains the copper traces forming the coil elements, precisely designed for optimal signal reception and transmission

- Signal Processing Circuits: High-speed analog and digital processing circuits that amplify and condition MR signals

- Gradient Control Systems: Precision current switching circuits that generate magnetic field gradients for spatial encoding

- Patient Safety Circuits: Integrated monitoring and protection systems ensuring patient safety during scanning procedures

The signal processing begins when hydrogen protons in the patient's body are excited by RF pulses generated through transmit coils. The resulting MR signals, typically in the millivolt range, must be captured with maximum efficiency while minimizing noise interference. Our high-frequency PCB expertise ensures optimal signal integrity across the entire RF spectrum used in MRI applications.

Modern MRI systems demand multi-channel arrays that can be applied to various target organs and provide high parallel imaging performance, requiring sophisticated PCB designs that manage complex signal routing while maintaining electromagnetic compatibility.

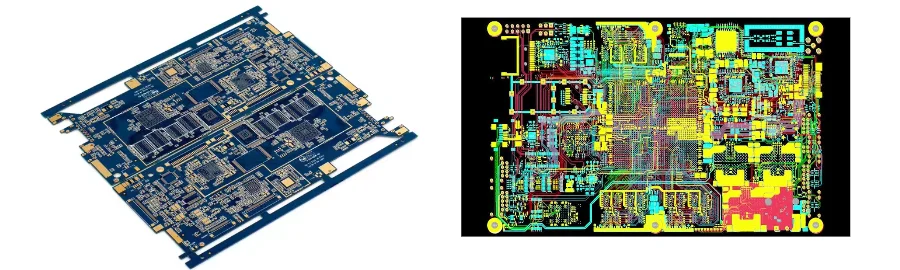

Flexible and Rigid-Flex MRI PCB Solutions

The evolution toward flexible PCB technology has revolutionized MRI coil design, enabling patient-conforming solutions that significantly improve both image quality and patient comfort. A 23-channel array designed based on a rigid-flex printed circuit board (PCB) enables adjusting the array to various anatomical sites individually for each patient.

Advanced Flexible PCB Architectures:

- Pure Flexible Designs: Ultra-thin polyimide-based circuits that conform to complex anatomical contours

- Rigid-Flex Hybrid Systems: The rigid part of the PCB houses the solder joints and lumped elements while the flexible portions contain copper traces

- Multi-Layer Constructions: Complex layer stack-ups supporting high-density interconnects and controlled impedance routing

- Stretchable Technologies: Advanced conductor materials enabling dynamic conformance to patient movement

Performance Benefits of Flexible MRI PCBs: Research demonstrates that when the coil is conformed to the phantom surface, a SNR gain up to 2 is achieved as compared to identical but planar RF coil. This significant improvement results from:

- Enhanced tissue coupling through closer proximity

- Reduced motion artifacts due to improved patient comfort

- Optimized field uniformity across imaging volumes

- Minimized electromagnetic interference from external sources

Our flexible PCB manufacturing capabilities support the most demanding MRI applications, from research-grade 7T systems to clinical 1.5T and 3T installations. The rigid-flex PCB is specified for >10,000 bending cycles with bending radii larger than 250 times the thickness of the flexible substrate, ensuring long-term reliability in clinical environments.

Multi-Channel RF Coil Array Design and Implementation

Modern MRI systems increasingly rely on sophisticated multi-channel RF coil arrays to achieve the parallel imaging capabilities required for fast, high-resolution scanning. This study presents the development and evaluation of a 16-channel general-purpose MRI coil array constructed using 50-micron copper foil sheets, demonstrating superior signal-to-noise ratio (SNR), lower noise correlation, and better parallel imaging performance.

Critical Design Parameters for Multi-Channel Arrays:

- Element Spacing and Geometry: Optimized coil element positioning to maximize SNR while minimizing inter-element coupling

- Decoupling Networks: Efficient mutual decoupling between receive elements and detuning between receive array and body coil was achieved

- Impedance Matching: Precise 50-ohm impedance matching across all channels for optimal power transfer

- Parallel Imaging Performance: Parallel imaging acceleration factors up to six through advanced array geometries

Manufacturing Excellence in Multi-Channel Systems: Phantom testing showed a 17-20% improvement in SNR with the copper foil coil, while noise correlation matrices indicated reduced interference between coil elements. This performance improvement is achieved through:

- Advanced conductor materials and geometries using 50-micron copper foil for optimal conductivity

- Precision manufacturing tolerances ensuring consistent performance across all channels

- Sophisticated grounding and shielding strategies minimizing electromagnetic interference

- Integrated component placement optimization for maximum signal integrity

Our SMT assembly capabilities enable the precise placement of miniature components required for multi-channel RF coil electronics, ensuring optimal performance across all frequency ranges. Three key parameters in designing high-performance RF coils are field efficiency, impedance mismatch, and interchannel coupling.

Advanced Manufacturing and Medical Device Compliance

MRI PCB manufacturing demands specialized processes that meet the unique requirements of medical device applications. ISO 13485 maintains the effectiveness of the medical device quality management system, thereby ensuring the safety and effectiveness of medical devices. Our comprehensive approach combines advanced materials with rigorous quality control protocols.

Specialized Manufacturing Processes:

- Medical-Grade Materials: Polyimide PCB materials feature excellent tensile strength, flexibility, high durability, thermal stability, and chemical resistance, making them perfect for medical devices

- Advanced Conductor Technologies: Screen-printed flexible MRI receive coils enable highly flexible, extremely lightweight conforming devices that exhibit similar to higher signal-to-noise ratio than conventional coils

- Precision Assembly: Our multilayer PCB expertise ensures complex layer stack-ups meet demanding signal integrity requirements

- Biocompatible Coatings: Adhesive PTFE sheets cover all flexible parts providing chemical resistance and patient safety

Comprehensive Quality Management:

- Process Validation: The process used to manufacture medical PCBs must be validated for accuracy and safety, including validating temperature, humidity, and pressure of the manufacturing environment

- Testing Protocols: MRI RF coil fabrication requires testing for impedance matching, radiation, and interchannel coupling using advanced network analyzers

- Regulatory Compliance: All medical PCBs must meet UL certification standards, involving testing of various electrical and mechanical parameters

- Documentation Standards: Complete traceability and documentation supporting FDA 510(k) submissions and international regulatory requirements

Our turnkey assembly services integrate comprehensive testing protocols ensuring every MRI PCB meets the highest medical device standards from prototype through volume production.

Why Choose HILPCB for MRI PCB Manufacturing

Choosing HILPCB for MRI PCB manufacturing means partnering with a leader in medical electronics who understands the critical importance of signal integrity, patient safety, and regulatory compliance. Our facility integrates Automated Optical Inspection (AOI), X-ray inspection, and visual inspection to ensure complete solder joint integrity, component alignment, and solder paste deposition consistency across all production runs.

We apply inline and offline inspection during surface-mount and through-hole assembly to verify hidden solder connections, especially under BGA, QFN, and CSP components commonly used in MRI electronics. These non-destructive tests identify solder voids, bridging, and cold joints before final integration, providing confidence for high-reliability medical applications.

Our Competitive Advantages:

- Medical Device Expertise: ISO 13485-certified quality management systems with deep understanding of FDA and international medical device regulations

- Advanced Capabilities: State-of-the-art manufacturing equipment supporting both large-volume assembly and precision prototyping

- Material Innovation: Access to cutting-edge medical-grade substrates including polyimide, PTFE composites, and specialized conductor technologies

- Comprehensive Testing: In-house testing capabilities covering electrical performance, biocompatibility, and mechanical reliability requirements

In addition to manufacturing excellence, our inspection ecosystem includes ICT (in-circuit test), functional test, and high-voltage testing, ensuring that every assembled MRI PCB leaves our facility with complete electrical validation. From single prototypes to volume production, our processes guarantee traceable quality across all PCB types and complexity levels.

MRI PCB Design and Manufacturing FAQ

What makes MRI PCBs different from standard electronic PCBs?

MRI PCBs must operate in extremely strong magnetic fields while processing weak RF signals with exceptional precision. They require specialized materials, precise impedance control, and compliance with medical device regulations including ISO 13485 and FDA requirements.

How do flexible MRI PCBs improve image quality?

Flexible PCBs enable closer tissue coupling, with research showing SNR gains up to 2x compared to rigid coils. This improvement results from better anatomical conformance, reduced motion artifacts, and optimized electromagnetic coupling.

What are the key design considerations for multi-channel MRI arrays?

Critical factors include inter-element decoupling, impedance matching across all channels, parallel imaging capability, and electromagnetic compatibility. Three key parameters in designing high-performance RF coils are field efficiency, impedance mismatch, and interchannel coupling.

Which materials are best suited for MRI PCB applications?

Medical-grade polyimide offers optimal flexibility and biocompatibility, while PTFE provides excellent dielectric properties. These materials feature excellent tensile strength, flexibility, thermal stability, and chemical resistance required for medical devices.

How does HILPCB ensure regulatory compliance for medical applications?

We maintain ISO 13485 certification and implement comprehensive quality management systems covering design controls, risk management, process validation, and complete traceability throughout manufacturing.

What testing capabilities does HILPCB provide for MRI PCBs?

Our testing includes network analysis for S-parameter measurements, specialized MRI phantom testing, biocompatibility validation, and electrical safety testing using advanced inspection systems including AOI and X-ray inspection.

Can HILPCB support both prototype and production volumes?

Yes, our capabilities span from quick-turn prototypes for R&D applications through high-volume production supporting global MRI manufacturers. Our scalable manufacturing processes ensure consistent quality across all volume levels.