The gap between product concept and shipping hardware kills more projects than technical challenges. Design completes on schedule but prototypes arrive three weeks late. Prototypes work but production boards fail at 30% rate. Each transition point between vendors creates delays, miscommunication, and expensive rework cycles.

Integrated development and manufacturing eliminates these transition failures. When the same organization handles design support, prototyping, testing, and production, knowledge transfers seamlessly between phases without the friction of multiple vendors.

The NPI Process That Actually Works

New product introduction fails most often at transition points. Understanding where problems occur helps you structure development to avoid common pitfalls that extend schedules and inflate budgets.

Phase 1: Feasibility and Planning (Week 1-2)

Many product ideas contain hidden impossibilities discovered only after significant investment. Processing requirements exceed available microcontroller capabilities. Physical size constraints prevent adequate battery capacity. Component costs make target pricing impossible. Early feasibility assessment identifies showstoppers before committing full development resources.

Technical feasibility review examines:

- Power budget analysis matching battery size to operating time requirements

- Thermal assessment verifying adequate cooling for power dissipation levels

- RF link budget calculations for wireless communication range

- Component availability evaluation preventing designs around unobtainable parts

- Manufacturing capability assessment ensuring proposed design can actually be built

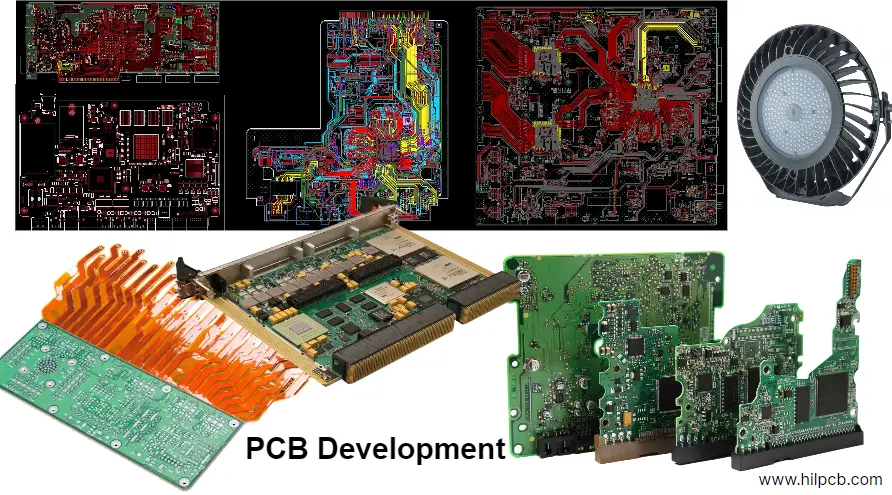

Our PCB engineering team conducts feasibility analysis during concept phase, identifying potential issues when alternative approaches remain viable and cost-effective to explore.

Phase 2: Design and Prototype Iteration (Week 3-8)

First prototypes rarely work perfectly. Debugging identifies design errors, component issues, and specification shortcomings. Quick iteration cycles separate successful products from expensive failures. Fast prototyping accelerates this critical learning phase.

Our 48-72 hour PCB prototyping turnaround enables weekly iteration cycles:

- Week 3: Initial design and first prototype order

- Week 4: First boards arrive, bring-up and testing begins

- Week 5: Rev B design addressing issues, second prototype order

- Week 6: Rev B testing and validation

- Week 7: Rev C optimization and cost reduction

- Week 8: Final prototype validation before production transition

Traditional prototyping with 2-3 week lead times would extend this phase to 15-20 weeks for the same number of iterations.

Phase 3: Production Transition (Week 9-12)

Pre-production builds validate manufacturing processes before volume commitments. Assembly yields reveal design-for-manufacturing issues missed during prototype builds with hand-selected components. Test procedures finalize and documentation completes. This phase prevents expensive problems during volume production.

Pre-production quantities of 25-100 units serve multiple purposes:

- Process validation for PCB assembly optimization

- Test procedure debug and timing verification

- Documentation completeness verification

- Component supply chain qualification

- Quality assurance procedure validation

Manufacturing process optimization includes reflow profile development, inspection strategy selection, and test fixture design. Our assembly team develops optimized processes specifically for your design requirements during this phase.

Parallel Development Strategies

Traditional sequential development wastes 40-60% of calendar time waiting for handoffs between phases. Design completes, then prototypes order. Prototypes arrive, then testing begins. Testing completes, then manufacturing planning starts. Each handoff creates delays while next team establishes context.

Overlapping Activities Compresses Timelines

Parallel development proceeds activities wherever dependencies permit:

- Mechanical design continues during electrical schematic development, with teams coordinating on connector locations and mounting requirements

- Test procedure development begins during prototype phase rather than waiting for production readiness

- Manufacturing process development uses early prototypes to optimize reflow profiles rather than waiting for design freeze

- Component qualification proceeds alongside design validation

- Documentation development parallels hardware development

This parallelism typically reduces total development time by 35-50% compared to sequential approaches.

The Coordination Challenge

Parallel activities require tight coordination and disciplined change control. Regular cross-functional meetings ensure all teams stay synchronized on current status and upcoming changes. Version control systems track design evolution and prevent confusion when rapid iteration creates multiple concurrent versions.

Clear communication protocols establish:

- Who needs notification of which changes and when

- How to handle conflicts between parallel activities

- Escalation procedures for blocking issues

- Decision-making authority at each development stage

Our integrated team structure facilitates natural coordination through proximity and shared objectives, avoiding the miscommunication common when design and manufacturing occur at separate organizations.

Risk Management Throughout Development

Every development project faces technical, schedule, and cost risks. Proactive risk identification and mitigation prevents surprises that derail projects and destroy budgets.

Technical Risk Mitigation Strategies

Unproven technologies carry implementation risk that can block entire projects. Proof-of-concept prototypes demonstrate feasibility before committing full development resources. Critical functions undergo early testing to validate assumptions before detailed design lock-in. Alternative approaches develop in parallel when primary approach success remains uncertain.

Component availability represents increasing risk:

- Semiconductor shortages create 26+ week lead times for formerly common parts

- Manufacturers discontinue product lines with little warning

- Price volatility affects product economics and margin assumptions

- Single-source components create supply chain vulnerability

Our procurement team monitors supply conditions and provides advance warning of potential issues. We work with clients to identify alternative components and design flexibility that accommodates multiple part options when primary choices present supply risk.

Schedule Buffer Strategy

Realistic scheduling accounts for iteration cycles and unexpected challenges. Schedule buffers at critical milestones accommodate problem resolution without impacting delivery commitments:

- Prototype testing buffer allows extra iteration if first build reveals major issues (2-3 weeks)

- Pre-production buffer permits process optimization before volume commitments (1-2 weeks)

- Production ramp buffer accommodates yield improvement and process stabilization (2-4 weeks)

Milestone-based development with clear deliverables provides accountability and visibility. Regular progress reviews identify problems early when corrective action costs less and options remain more flexible.

Component Sourcing and Supply Chain Management

Supply chain disruptions threaten more projects than technical challenges. Component availability determines whether products ship on schedule or sit waiting for parts. Proactive supply chain management prevents these delays.

The Turnkey vs Consignment Decision

Turnkey assembly means we source all components. Consignment means you provide components. Neither approach is universally better - it depends on your situation and priorities.

Turnkey Assembly Advantages:

- Single point of responsibility for complete product

- Leverage our supplier relationships and volume pricing

- Faster procurement through established channels

- We absorb component lead time risk

- Simplified logistics and inventory management

Consignment Assembly Advantages:

- You control component sourcing and maintain supplier relationships

- Transparent component costs without procurement margin

- Better for existing inventory or long-lead items you already ordered

- Preferred when you have proprietary or programmed components

Many customers use hybrid approach - we source commodity components (resistors, capacitors, standard ICs) while you provide critical components like ASICs, programmed microcontrollers, or long-lead items in your existing inventory.

Supply Chain Risk Management

Component obsolescence threatens product lifecycle. Parts get discontinued, leaving existing designs unsupportable. Proactive obsolescence management identifies at-risk components before they become unavailable:

- Monitoring component lifecycle status

- Advance notification of pending obsolescence

- Research and qualification of suitable replacements

- Design modifications needed for alternative components

This maintains product supportability throughout intended lifecycle, preventing expensive redesigns or end-of-life situations caused by component unavailability.

Testing and Validation Strategy

Appropriate test strategy balances thoroughness with efficiency. Insufficient testing misses defects that appear in field. Excessive testing wastes time and money. Strategy depends on circuit complexity, production volume, and quality requirements.

Prototype Validation Testing

Early prototypes undergo comprehensive testing to validate design before production:

- Initial power-on verification confirms proper voltage regulation and current consumption

- Functional testing validates each subsystem operation

- Performance characterization measures actual behavior against specifications

- Environmental testing confirms operation across temperature range

- Compliance testing verifies regulatory requirements (FCC, CE, safety standards)

Issues discovered during prototype testing get fixed before production, when corrections cost 10-100× less than field failures.

Production Testing Strategy

Volume production requires efficient testing that catches defects without creating bottlenecks:

- Flying probe testing for low volume (5-500 boards) - no fixture cost, flexible for design changes

- In-circuit testing (ICT) for volume production (1000+ boards/year) - faster test times, comprehensive coverage

- Functional testing verifies end-to-end system operation under real conditions

- Automated optical inspection (AOI) catches assembly defects during production

Our PCB testing capabilities include all methods, with recommendations based on your specific volume and quality requirements.

From initial concept through volume production, HILPCB development services accelerate your path to market while reducing risk. Visit www.hilpcb.com/en/ to discuss your development needs.