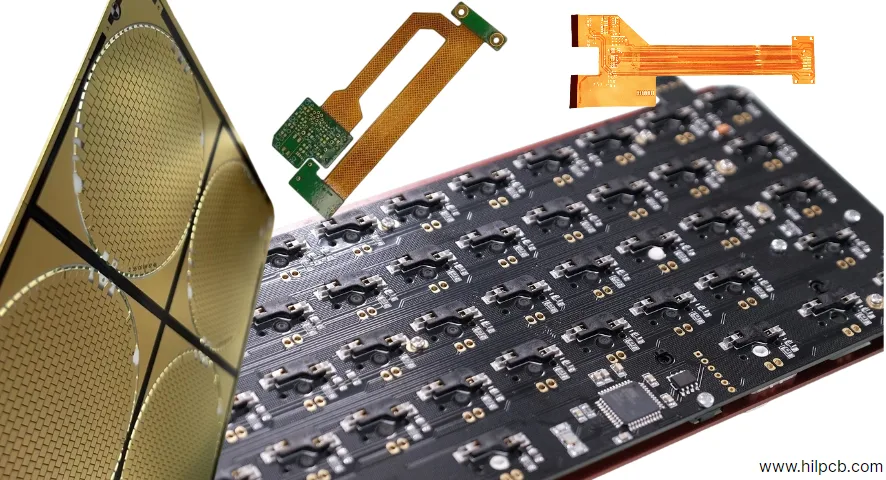

Speed-to-market demands rapid PCB prototyping without compromising quality or capability. While many advertise "quick turn PCB prototype services," few deliver genuine value: 24-hour PCB prototyping for design validation, low-volume PCB prototyping (1-50 boards) with production processes, HDI PCB prototyping with microvias and fine-pitch assembly, rigid-flex PCB prototyping for 3D packaging, or Rogers PCB prototyping for RF circuit verification.

The challenge extends beyond fast delivery. Prototype PCB manufacturing must match production processes for valid testing. Rapid PCB prototyping requires flexible iteration support for design changes. Engineering PCB prototyping needs DFM analysis to prevent production issues. Turnkey PCB prototyping includes component sourcing and assembly. Medical/automotive prototyping demands certified processes.

HILPCB provides comprehensive China PCB prototyping from same-day PCB Fabrication to complete turnkey PCB Assembly. Our capabilities include fast PCB prototype manufacturing (24-48 hour delivery), low MOQ prototyping (1-50 boards), all technologies (HDI, rigid-flex, Rogers, metal core), assembly services with component sourcing, and seamless transition to PCB Production.

Complete PCB Prototyping Capabilities

Our China PCB prototyping facility as a professional PCB Manufacturer handles all circuit board technologies with quick turnaround and production-quality processes.

Quick Turn Timelines:

- 24-hour PCB prototyping: 2-4 layer FR4, standard specifications

- 48-hour rapid prototyping: up to 8 layers, basic HDI available

- 72-hour express service: complex multilayer, specialty materials

- 5-7 day advanced prototyping: rigid-flex, high layer count, Rogers materials

Prototype Quantity Flexibility:

- Ultra-low volume: 1-5 boards for initial design validation

- Low-volume prototyping: 5-20 boards for team distribution and testing

- Pre-production: 20-50 boards for manufacturing validation

- Pilot run: 50-200 boards for production process verification

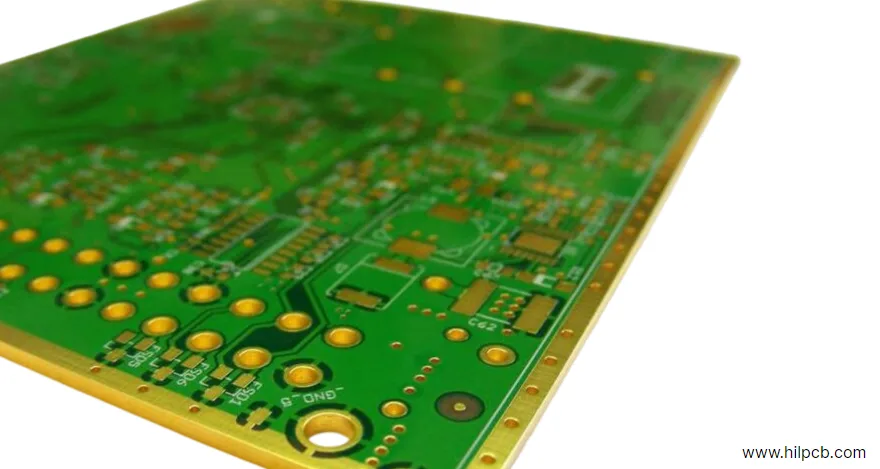

Technology Capabilities:

- Standard rigid PCB prototyping: 2-32 layers, FR4 materials

- HDI PCB prototyping: laser-drilled microvias, 2/2mil traces

- Flexible PCB prototyping: 1-8 layer flex circuits

- Rigid-flex prototyping: complex hybrid constructions

- Metal core prototyping: aluminum/copper base for thermal testing

- RF prototyping: Rogers, Taconic, Arlon materials with impedance control

Precision Specifications:

- Layer count: 2-64 layers with sequential lamination

- Line width/spacing: 2/2mil minimum (HDI), 3/3mil standard

- Via technology: through-hole, blind, buried, microvias

- Materials: complete range from FR4 to Rogers to ceramics

Fast PCB Prototype Manufacturing Process

Speed requires optimized workflows without quality compromise supported by our modern PCB Factory infrastructure. Our quick turn processes maintain production standards.

Expedited Design Processing:

- Instant DFM analysis: automated checking within hours of file upload

- Engineering review: identifies potential issues before fabrication

- Material availability check: confirms stock or fast-track procurement

- Production scheduling: priority slots for quick turn orders

Accelerated Fabrication:

- Panel optimization: maximizes prototype efficiency

- Priority processing: moves through production stages ahead of standard orders

- Continuous monitoring: tracks progress, prevents delays

- Quality verification: full AOI, electrical testing, inspection included

Rush Assembly Services:

- Component sourcing: expedited procurement from authorized distributors

- SMT assembly: handles 01005 to large connectors, fine-pitch BGAs

- Quick turn assembly: 24-48 hour turnaround with components in stock

- Testing included: AOI, X-ray (for BGAs), functional testing available

Flexible Iteration Support:

- Easy design changes: accommodate revisions between prototype builds

- Version control: tracks design iterations and changes

- Parallel builds: can run multiple design variants simultaneously

- Engineering consultation: technical support for optimization

Our integrated PCB Services approach streamlines the entire prototyping workflow from initial design review through final testing and delivery.

Advanced Prototype Technologies

Complex designs require advanced prototyping capabilities beyond standard quick turn services through our comprehensive PCB Manufacturing expertise.

HDI PCB Prototyping:

- Laser drilling: creates microvias 50-150µm diameter

- Any-layer structures: stacked/staggered microvias

- Fine-line imaging: 2/2mil traces with laser direct imaging

- Applications: smartphone, wearable, miniaturized medical devices

Rigid-Flex PCB Prototyping:

- Sequential lamination: bonds rigid and flex sections

- Multiple flex zones: supports complex 3D packaging

- Stiffener placement: validates mechanical design

- Dynamic flex testing: verifies bend reliability

- Applications: aerospace, medical implants, compact consumer blog

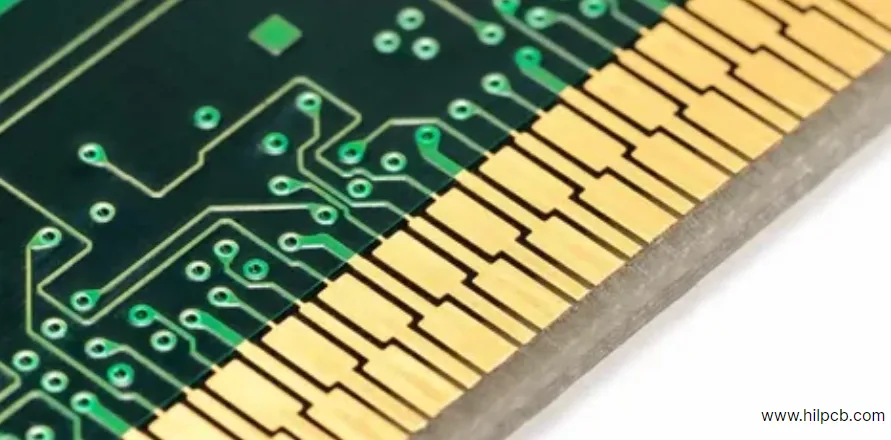

Rogers & RF PCB Prototyping:

- Material options: RO4003C, RO4350B, RT/duroid, Taconic, Arlon

- Impedance control: ±3Ω tolerance with TDR verification

- Mixed dielectrics: combines Rogers and FR4 for cost optimization

- RF testing: S-parameter measurement available

- Applications: 5G, radar, satellite, automotive RF systems

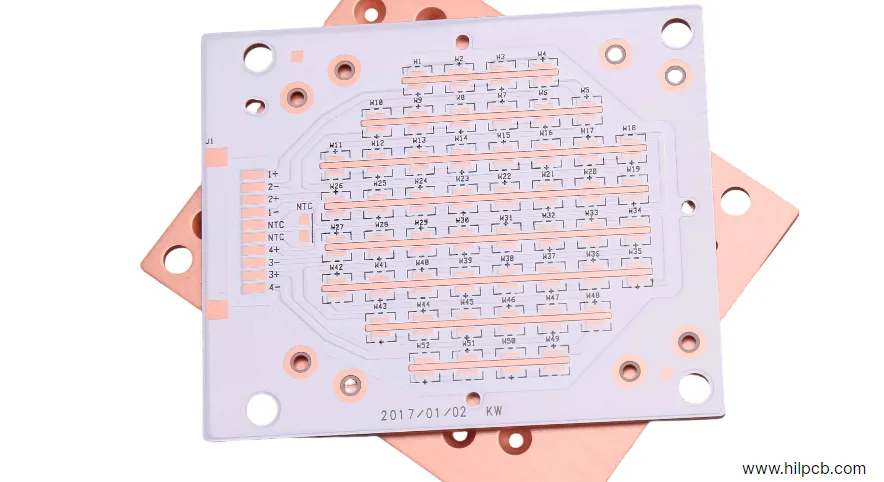

Metal Core Prototyping:

- Aluminum core: 1-10 W/mK thermal conductivity

- Copper core: 200-400 W/mK for maximum heat dissipation

- Thermal via processing: validates heat transfer design

- Applications: LED prototypes, power electronics validation

Turnkey PCB Prototyping Services

Complete solution from design files to tested assemblies accelerates development cycles through our full-service PCB Company capabilities.

Full Turnkey Prototyping:

- PCB fabrication: all technologies and materials

- Component sourcing: procurement from authorized distributors

- SMT/through-hole assembly: complete component placement

- Testing and programming: functional validation, firmware loading

- Single point of contact: simplifies coordination

Component Sourcing for Prototypes:

- Authorized distributor network: Arrow, Avnet, Digi-Key, Mouser, TTI

- Fast procurement: leverages stock availability for quick delivery

- Small quantity handling: sources low-MOQ components for prototypes

- Alternative recommendations: suggests substitutes for unavailable parts

- Counterfeit prevention: verified supply chain ensures authentic components

Assembly & Testing Services:

- SMT assembly: 01005 components to large connectors, 0.3mm pitch BGAs

- Through-hole: selective soldering for mixed technology boards

- BGA rework: X-ray inspection and rework capability

- Functional testing: power-on validation, programming, calibration

- Debug support: engineering assistance for non-functioning prototypes

Consignment Prototyping:

- Customer-provided components: you supply parts, we assemble

- Inventory management: tracks customer-supplied materials

- Kitting verification: ensures complete component sets

- Best for: proprietary components, existing inventory, cost visibility

Prototype-to-Production Transition

Prototyping with production processes ensures smooth scaling and prevents surprises through collaboration with our PCB Design engineering team.

Production-Intent Prototyping:

- Same equipment: prototypes use production tooling and processes

- Same materials: validates actual production material performance

- Same testing: full electrical and functional verification

- Valid data: prototype results predict production behavior

Design Validation Support:

- DFM analysis: identifies manufacturing issues early

- Design optimization: recommends improvements for yield and cost

- Material selection: consultation on optimal substrates

- Testability review: ensures adequate access for production testing

Pre-Production Builds:

- Pilot runs: 50-200 boards validate production processes

- Process documentation: develops manufacturing work instructions

- Tooling development: creates test fixtures and assembly aids

- Yield analysis: identifies and resolves systematic issues

Scalability Planning:

- Volume pricing: provides production cost estimates

- Lead time projections: forecasts production schedules

- Capacity planning: reserves production slots for launch

- Supply chain: establishes component sourcing for volume

HILPCB Prototyping Excellence

Fast Turnaround Options:

- 24-hour prototyping: 2-4 layer FR4

- 48-hour quick turn: up to 8 layers, basic HDI

- 72-hour express: complex multilayer, specialty materials

- 5-7 day advanced: rigid-flex, high layer count

Complete Technology Range:

- 2-64 layers, 2/2mil traces, microvias

- HDI, rigid-flex, Rogers, metal core, ceramics

- All surface finishes: ENIG, immersion silver, OSP, HASL

- Production-quality processes for valid testing

Low MOQ Flexibility:

- 1-50 boards for prototyping

- No setup fees for standard processes

- Easy design iterations

- Parallel variant builds available

Integrated Services:

- Turnkey prototyping: fabrication + sourcing + assembly

- Component procurement from authorized distributors

- Testing: AOI, X-ray, electrical, functional

- Engineering support: DFM, design optimization, debug assistance

Seamless Production Transition:

- Same processes as production

- Volume pricing estimates

- Capacity planning and scheduling

- Supply chain establishment

From concept validation to pre-production, HILPCB delivers fast PCB prototyping with production-quality processes, enabling confident design decisions and smooth scaling to volume manufacturing. Our comprehensive PCB Solutions ensure that prototype boards accurately represent production performance.

Frequently Asked Questions

Q1: What's the fastest PCB prototyping turnaround available? 24-hour service for 2-4 layer FR4 boards with standard specs. 48-hour for up to 8 layers or basic HDI. 72-hour for complex multilayer. Quick turn costs 50-150% premium over standard 5-7 day service.

Q2: What's the minimum order quantity for PCB prototyping? 1 board minimum for most technologies. Typical prototyping quantities: 5-10 boards for testing and team distribution, 20-50 boards for pre-production validation. No setup fees for standard processes.

Q3: Can prototypes use the same processes and materials as production? Yes, prototypes use production equipment and processes for valid testing results. Same materials, same quality standards, same testing. This ensures prototype performance predicts production behavior and enables smooth scaling.