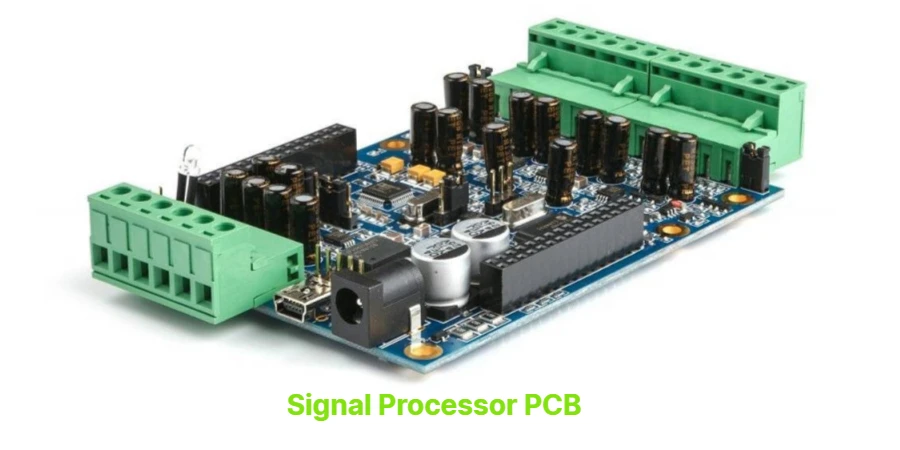

HILPCB delivers comprehensive PCB manufacturing and assembly solutions for advanced signal processing applications in telecommunications, data communications, and broadcast systems. Our expertise encompasses digital signal processor PCBs for baseband processing, FPGA-based accelerators for network functions, and mixed-signal boards that bridge analog RF interfaces with digital processing cores. We support the full spectrum of signal processing requirements from prototype development through high-volume production for global telecommunications infrastructure.

Signal processing technology drives modern communications networks, enabling everything from 5G wireless systems to high-speed optical transport networks. These sophisticated PCBs must handle multi-gigabit data streams while maintaining exceptional signal integrity and meeting stringent telecommunications standards. HILPCB combines advanced manufacturing capabilities with deep technical expertise to produce signal processor boards that deliver reliable performance in mission-critical communications applications.

Signal Processor PCB Design Requirements

Signal processor PCB design for telecommunications applications demands meticulous attention to high-speed digital interfaces, memory subsystems, and power delivery networks. Modern communications equipment integrates multiple processing elements including DSPs for baseband operations, FPGAs for protocol acceleration, and network processors for packet handling, all operating in concert to deliver seamless connectivity.

Core Design Considerations:

• High-Speed Memory Interfaces: DDR4 and DDR5 memory subsystems operating at speeds exceeding 3200 MT/s require precise length matching and impedance control to maintain signal integrity across parallel data buses

• Multi-Gigabit Serial Links: SerDes interfaces running at 25 Gbps and beyond demand careful differential pair routing with minimal via transitions and optimized return paths to prevent signal degradation

• Clock Distribution Networks: Low-jitter clock trees distributing reference signals to multiple processing elements while maintaining phase coherence critical for synchronous telecommunications systems

• Power Delivery Architecture: Multi-phase voltage regulators providing stable power to processors with dynamic loads ranging from milliwatts in idle states to hundreds of watts during peak processing

Communications infrastructure equipment operates in diverse environments from climate-controlled data centers to outdoor cellular sites experiencing temperature extremes. High-speed PCB designs must accommodate these environmental variations while maintaining consistent electrical performance across the operating range.

Signal Integrity Management:

Digital signal processor boards handle complex modulation schemes and error correction algorithms that require pristine signal quality throughout the processing chain. Crosstalk mitigation through proper stackup design and trace spacing prevents inter-symbol interference that could degrade bit error rates. Ground plane partitioning isolates sensitive analog-to-digital converters from noisy digital switching circuits while maintaining a continuous return path for high-speed signals.

Manufacturing Processes for High-Performance Signal Processing PCBs

Professional signal processor PCB manufacturing leverages advanced fabrication technologies to achieve the fine geometries and tight tolerances demanded by modern telecommunications applications. Sequential build-up processes enable complex via structures that optimize signal routing while minimizing parasitic effects that could compromise high-frequency performance.

Advanced Manufacturing Technologies:

HDI PCB construction techniques facilitate the integration of high-pin-count BGA packages with thousands of connections in compact form factors. Microvias with diameters approaching 75 micrometers connect dense routing layers while maintaining the impedance control essential for multi-gigabit interfaces.

Rigid-flex PCB solutions enable innovative packaging approaches for signal processing modules that must fit within space-constrained telecommunications equipment while providing reliable interconnections between processing boards and I/O interfaces.

Material Selection and Stackup Design:

• Low-Loss Dielectrics: Materials with controlled dielectric constants and minimal dissipation factors preserve signal quality across long transmission lines in backplane applications

• Thermally Enhanced Substrates: Metal core and ceramic-filled laminates provide superior thermal conductivity for boards dissipating significant power from high-performance processors

• Impedance Control Structures: Precision etching and plating processes maintain impedance tolerances within ±5% for critical high-speed differential pairs

• Surface Finish Options: ENEPIG and other advanced finishes ensure reliable solder joints for fine-pitch components while maintaining excellent shelf life

Manufacturing quality control incorporates automated optical inspection at multiple stages to detect defects before they impact downstream processes. Electrical testing validates continuity, isolation, and impedance characteristics ensuring boards meet design specifications before proceeding to assembly.

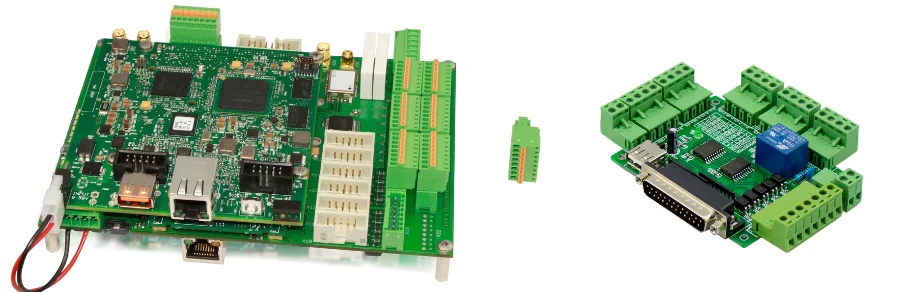

Assembly Solutions for Communications Signal Processing Equipment

Signal processor PCB assembly for telecommunications applications requires sophisticated processes capable of handling diverse component technologies from ultra-fine-pitch digital processors to high-power RF amplifiers. Modern assembly lines must accommodate the increasing complexity of communications boards that integrate thousands of components in dense configurations.

Precision Assembly Technologies:

SMT assembly equipment with advanced vision systems ensures accurate placement of 01005 passive components and micro-BGA packages with pitches below 0.4mm. Nitrogen reflow atmospheres prevent oxidation during soldering while multi-zone thermal profiles accommodate components with varying thermal masses.

Critical Component Integration:

• High-Performance Processors: DSPs and FPGAs with thousands of connections requiring precise coplanarity control and void-free solder joints for reliable operation

• Memory Modules: High-speed DDR4/DDR5 memory devices demanding careful handling to prevent electrostatic damage and maintain signal timing requirements

• Optical Transceivers: Pluggable modules for fiber optic interfaces requiring precise mechanical alignment and thermal management for stable operation

• RF Components: Filters, amplifiers, and mixers for wireless interfaces necessitating controlled impedance transitions and proper grounding techniques

Assembly validation extends beyond electrical testing to include environmental stress screening that identifies early failures through temperature cycling and vibration testing. These processes prove particularly valuable for boards destined for deployment in harsh telecommunications environments where field failures carry significant operational and financial consequences.

Applications in Telecommunications Infrastructure

Signal processor PCBs form the computational foundation of modern telecommunications networks, enabling the complex signal manipulation and protocol processing required for reliable communications services. From wireless base stations to optical transport systems, these boards deliver the processing power necessary to handle exponentially growing data traffic.

5G and Wireless Infrastructure:

Next-generation wireless networks rely on sophisticated signal processing to implement massive MIMO antenna arrays, beamforming algorithms, and advanced modulation schemes. Base station equipment incorporates multiple signal processor boards working in parallel to handle dozens of antenna elements while maintaining precise phase and amplitude control. Backplane PCB designs provide high-bandwidth interconnections between processing modules, radio units, and network interfaces in modular telecommunications platforms.

Optical Network Equipment:

Coherent optical systems employ digital signal processors to compensate for transmission impairments including chromatic dispersion, polarization mode dispersion, and nonlinear effects. Forward error correction algorithms running on specialized processors enable error-free transmission over thousands of kilometers of optical fiber.

Professional Manufacturing Services and Quality Assurance

HILPCB delivers end-to-end signal processor PCB manufacturing and assembly solutions that help telecom and networking equipment manufacturers reduce time-to-market, ensure reliability, and simplify supply chain management. From early design consultation to high-volume production, our team ensures every board meets the stringent requirements of high-speed and carrier-grade applications.

Our engineering support services are designed to reduce design risks and accelerate project success. We provide signal integrity and thermal simulations to validate designs before fabrication, rapid prototyping within 24–72 hours to verify concepts quickly, and design-for-manufacturing recommendations to improve yields, lower production costs, and enhance long-term reliability. These services allow customers to move from concept to production with confidence and speed.

Manufacturing excellence is at the core of HILPCB. Our turnkey assembly services manage everything from component sourcing to final testing, ensuring genuine parts and eliminating the risks of counterfeits. Certified to ISO 9001:2015, IPC-A-610 Class 3, and IPC J-STD-001, we support NEBS Level 3 and Telcordia standards for carrier-grade telecom equipment. By partnering with us, customers gain a reliable manufacturing partner that can scale from prototypes to mass production, guaranteeing performance, compliance, and global market readiness.

Frequently Asked Questions About Signal Processor PCB

Q: What makes signal processor PCB design different from general digital PCBs?

A: Signal processor PCBs require exceptional attention to high-speed interfaces, memory timing, and power delivery networks. These boards typically feature controlled impedance routing for multi-gigabit signals, sophisticated power management for dynamic processor loads, and thermal solutions for components dissipating tens to hundreds of watts.

Q: Which PCB materials are optimal for high-speed signal processing applications?

A: Material selection depends on specific application requirements. Standard FR-4 materials suffice for many digital processing applications up to 10 Gbps. Higher-speed interfaces benefit from low-loss materials like Megtron or Tachyon that maintain signal integrity at frequencies exceeding 20 GHz.

Q: How do you ensure reliability for telecommunications-grade signal processor PCBs?

A: Reliability assurance begins with robust design practices including proper derating, redundancy, and thermal management. Manufacturing processes maintain tight control over critical parameters while comprehensive testing validates performance across environmental extremes.

Q: Can you support both prototype development and volume production?

A: Yes, HILPCB provides seamless scaling from initial prototypes through full production volumes. Our quick-turn prototype services accelerate development cycles while our volume manufacturing capabilities support large-scale telecommunications deployments.