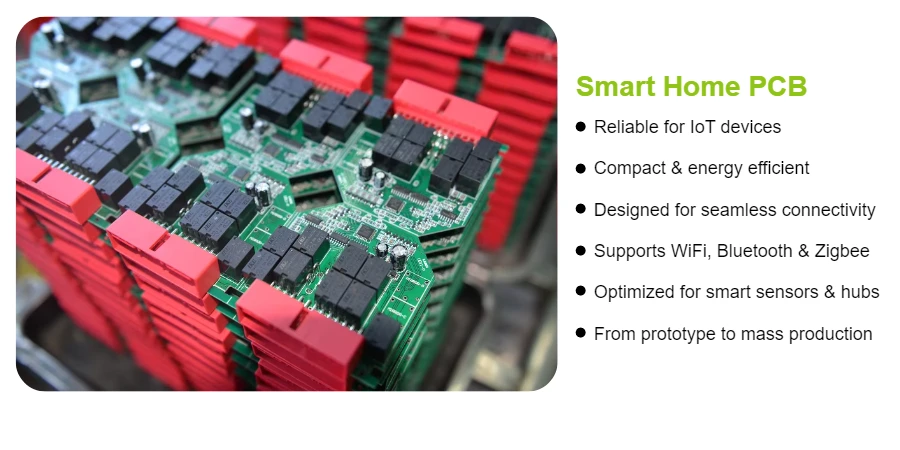

At Highleap PCB Factory, we manufacture circuit boards for every smart home application imaginable—and far beyond. While this guide focuses on smart home and IoT PCB solutions, our comprehensive manufacturing capabilities extend to automotive electronics, medical devices, industrial automation, and consumer electronics. From basic single-double layer PCB designs to complex high-frequency PCB for 5G applications, we deliver complete PCB manufacturing and SMT assembly services. Whether you're developing smart speakers, security cameras, or next-generation autonomous vehicles, our advanced facility produces reliable circuit boards from prototype through millions of units.

Comprehensive Smart Home PCB Applications

The smart home market encompasses hundreds of device categories, each requiring specialized PCB designs optimized for connectivity, power efficiency, and environmental durability.

Voice-Controlled Devices: Smart speaker PCB designs integrate powerful processors, multiple microphone arrays, and high-quality audio amplifiers. Our multilayer PCB solutions provide excellent signal isolation between digital and analog sections while maintaining compact form factors. Voice control PCB assemblies require specialized microphone placement and acoustic design considerations that our engineering team optimizes during development.

Security and Surveillance: Security camera PCB manufacturing demands high-speed processing capabilities for 4K video and AI analytics. Smart doorbell PCB designs must handle battery operation, wireless charging, and weatherproof sealing. Our experience with outdoor electronics ensures robust designs surviving extreme temperature variations and moisture exposure.

Climate and Energy Management: Smart thermostat PCB solutions integrate temperature sensors, display controllers, and HVAC interface circuits. Energy management PCB for smart outlets and meters require safety certifications and current monitoring capabilities. We provide complete regulatory compliance support including UL, FCC, and CE certifications.

Access Control and Security: Smart lock PCB designs balance security requirements with battery life constraints. These applications demand ultra-low power standby operation while maintaining instant response to unlock commands. Our power management expertise ensures months of operation from single battery charges.

Wireless Connectivity for Smart Home Devices

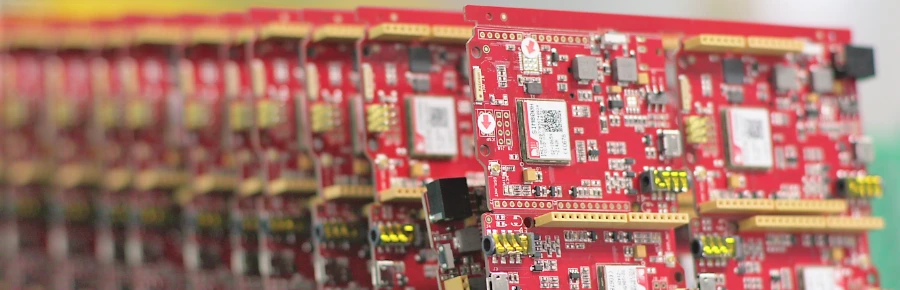

Smart home products depend on strong and reliable wireless links. In WiFi module PCB design, antenna placement, impedance control, and EMI suppression are critical. Our engineering approach ensures stable coverage and readiness for WiFi 6/7 standards, using optimized ground planes and shielding to handle high-speed signals without interference.

For Bluetooth PCB design, efficiency and low power are the priorities. From simple BLE sensors to advanced mesh hubs, our layouts support extended range, fast data rates, and long battery life. Mesh networking is carefully tuned to deliver seamless whole-home coverage without sacrificing reliability or energy efficiency.

Modern hubs combine multiple protocols—WiFi, Bluetooth, Zigbee, Z-Wave, and Thread—on a single PCB. To prevent cross-talk, we apply controlled stackups, isolation techniques, and antenna diversity. Our boards support PCB, external, and switchable antenna options, ensuring robust performance even in dense RF environments where many devices operate simultaneously.

Power Management and Energy Efficiency

Smart home devices must operate reliably for years while minimizing energy consumption and maintenance requirements.

Battery-Powered Devices: Ultra-low power design techniques extend battery life from months to years. Advanced power management ICs enable dynamic voltage scaling and power gating unused circuits. Our designs incorporate energy harvesting capabilities where applicable, including solar panels and kinetic energy capture.

Always-On Connectivity: Devices must maintain network connectivity while minimizing standby power consumption. Wake-on-WiFi and other low-power protocols enable instant response while preserving battery life. Power budgeting analysis ensures realistic operational expectations.

Charging and Power Delivery: Wireless charging integration requires specialized coil design and positioning. USB-C Power Delivery support enables rapid charging and data transfer. Our designs include comprehensive protection circuits preventing damage from power surges and incorrect connections.

Grid-Connected Devices: Smart outlets, switches, and circuit breakers require safety-certified designs handling line voltages. Isolation barriers prevent hazardous voltages from reaching user-accessible circuits. Current monitoring capabilities enable energy usage tracking and load management.

Advanced Manufacturing Capabilities

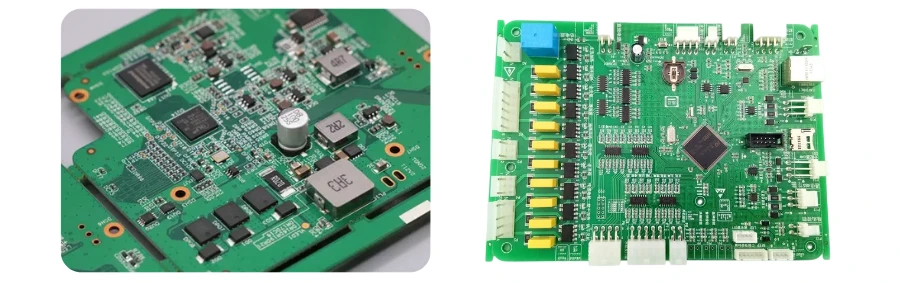

Smart home PCB production demands precision manufacturing meeting consumer electronics requirements for cost, quality, and reliability.

High-Density Interconnect (HDI): Miniaturization drives HDI technology adoption with microvias and blind/buried vias enabling maximum component density. Our HDI PCB capabilities support 0.1mm microvias and fine-pitch components essential for compact smart home devices.

Flexible and Rigid-Flex Solutions: Many smart home devices require flexible circuits for display connections, sensor placement, or space-constrained installations. Our rigid-flex PCB technology eliminates connectors while improving reliability and reducing assembly costs.

Environmental Compliance: Consumer electronics require RoHS compliance and halogen-free materials. Our halogen-free PCB materials meet environmental requirements without compromising performance. Lead-free assembly processes ensure complete compliance with global regulations.

Testing and Validation: Comprehensive testing validates performance, safety, and regulatory compliance. In-circuit testing, functional testing, and RF performance validation ensure products meet specifications. Our turnkey assembly services include complete testing and quality documentation.

Smart Home Integration and Ecosystems

Modern smart homes require seamless integration between devices and cloud services.

Cloud Connectivity: Secure communication with cloud services enables remote monitoring and control. Our PCB designs accommodate necessary security chips and encryption capabilities. Over-the-air update capabilities ensure devices remain current with latest features and security patches.

Interoperability Standards: Matter (formerly Thread) and other standards enable cross-platform compatibility. Our designs support multiple protocols ensuring devices work with Apple HomeKit, Google Assistant, Amazon Alexa, and other platforms.

Edge Computing: Local processing capabilities reduce cloud dependency and improve response times. AI acceleration chips enable advanced features like face recognition, voice processing, and predictive analytics running locally.

Home automation PCB hubs coordinate multiple devices and protocols. These complex designs require powerful processors, extensive memory, and multiple communication interfaces. Our system-level design expertise ensures optimal performance and reliability.

Your Complete Smart Home PCB Partner

While smart home applications represent one specialty, Highleap PCB Factory manufactures circuit boards for every electronic application. Our capabilities span from simple LED drivers to complex radar systems, from medical implants to aerospace electronics. This breadth of experience benefits all our customers—innovations developed for automotive applications improve smart home designs, while IoT miniaturization techniques enhance medical device development.

Whether you need a few prototypes or millions of production units, our integrated design, manufacturing, and assembly capabilities deliver superior products. From initial concept through regulatory approval to volume production, we provide comprehensive support ensuring your smart home products succeed in the competitive consumer market. By choosing Highleap PCB Factory, you gain a partner with deep technical expertise, global logistics capabilities, and unwavering commitment to quality.

Don't let PCB challenges slow your smart home innovation. Contact Highleap PCB Factory today for expert consultation and manufacturing solutions that bring your ideas to market faster and more reliably than ever before.

Frequently Asked Questions

Q1: Do you only manufacture smart home PCBs?

A: No, Highleap PCB Factory manufactures all types of PCBs for every industry—automotive, medical, aerospace, industrial, and consumer electronics. Smart home is one of many specialties.

Q2: What's your minimum order quantity for smart home PCBs?

A: No minimum for prototypes. Production orders start from 100 pieces with volume pricing available for larger quantities.

Q3: Can you handle IoT device certification requirements?

A: Yes, we provide complete documentation supporting FCC, CE, UL, and other certifications. Our designs meet regulatory requirements from the start.

Q4: What wireless protocols do you support?

A: All major protocols including WiFi 6/7, Bluetooth 5.0+, Zigbee, Z-Wave, Thread, and emerging standards. Our RF team optimizes antenna and EMI performance.

Q5: How do you ensure smart home PCB security?

A: Through secure element integration, hardware-based encryption, and secure boot capabilities. We also support trusted platform modules (TPM) and hardware security modules (HSM).

Ready to Revolutionize Smart Home Technology?

Partner with Highleap PCB Factory for all your electronic manufacturing needs. Our comprehensive capabilities, from smart home devices to automotive systems, ensure your products lead the market with superior performance and reliability.