As televisions evolve into intelligent, connected platforms, the underlying Smart TV PCB must deliver high performance, integration, and reliability. At Highleap PCB Factory (HILPCB), we specialize in fabricating and assembling Smart TV circuit boards tailored for 4K/8K displays, streaming modules, and voice-enabled user interfaces.

We combine multilayer PCB technology, RF expertise, and rigorous quality control to support global Smart TV OEMs from prototyping to large-scale production.

Smart TV PCB Architecture and Design Principles

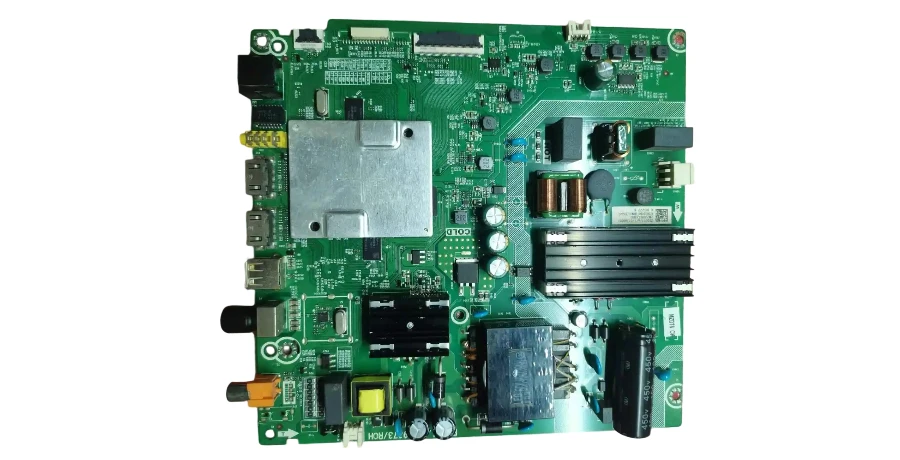

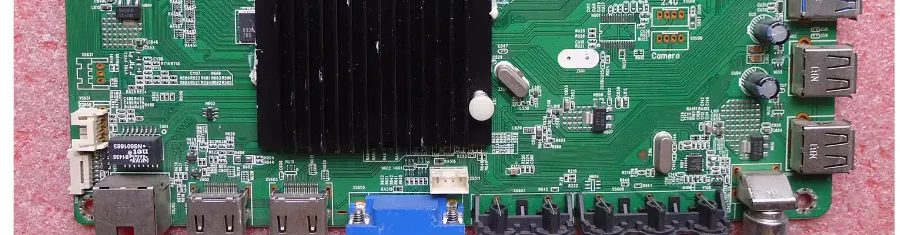

The Smart TV PCB acts as the central processing hub, coordinating video rendering, wireless communication, and system logic. Modern Smart TVs feature complex, compact boards integrating:

- High-performance SoCs with AI upscaling engines

- DDR4/LPDDR memory, NAND flash storage

- HDMI 2.1, USB 3.0, and Ethernet ports

- Dual-band Wi-Fi, Bluetooth, ZigBee modules

- Multi-rail power delivery networks

Most designs adopt multilayer PCB stackups (6–12 layers) with HDI routing and ground-signal-ground topologies for signal integrity.

Design Focus Areas:

- Controlled impedance for high-speed interfaces (e.g. HDMI)

- EMI shielding for RF zones and display drivers

- Heat spreading under SoC, RAM, and PMICs

- Isolation between analog AV paths and digital logic

📡 Wireless & Connectivity

- Dual-band Wi-Fi 6 and BT 5.0 integration

- ZigBee/Thread for smart home hubs

- Optional 5G and NFC modules

🧊 Thermal & EMI Control

- High-Tg [FR4 PCB](/products/fr4-pcb) materials for thermal resilience

- Copper pour zones and stitched thermal vias

- Segregated RF/digital shielding strategy

Smart TV PCB Fabrication and Material Considerations

Manufacturing Smart TV PCBs requires strict process control across mechanical, thermal, and electrical domains. These boards often span large surface areas and include both surface-mount and through-hole elements.

Fabrication Characteristics:

- 6 to 12-layer boards with low-loss high-frequency PCB materials

- ±10% impedance tolerance for HDMI, USB, and DDR signals

- ENIG/ENEPIG surface finishes for high-density BGA placement

- High-Tg PCB core materials for elevated reflow and ambient temperatures

Advanced builds may incorporate hybrid stackups or localized shielding enclosures. Our facility supports sequential lamination and via-in-pad structures to accommodate high net counts in constrained footprints.

🛠 Assembly Highlight: Precision Meets Scalability

Smart TV mainboards vary from compact embedded types to full-sized modular backplane assemblies. Our SMT lines accommodate fine-pitch SoCs, while box-build assembly services support integration into final chassis.

Key Assembly Capabilities:

- 0.3 mm BGA and 0201 passive placement accuracy

- Dual-sided reflow, selective wave soldering for legacy I/Os

- X-ray inspection for hidden joints and cavity packages

- Functional testing including HDMI loopback and RF verification

For enhanced durability, we also offer optional conformal coating and thermal interface application for heatsink-ready components.

Smart TV Applications and Deployment Environments

The Smart TV PCB must meet a wide spectrum of performance and environmental expectations — from consumer homes to hotel rooms and public signage.

Deployment Categories:

- Premium 4K/8K Smart TVs – High frame rate processing and voice assistant support

- Commercial Displays – Extended runtime and reliability for signage/video walls

- Hospitality & Embedded TVs – Custom firmware and remote control integration

- Gaming Displays – 120Hz+ refresh, VRR, G-Sync/FreeSync support

SMT Assembly and box-build assembly options support both OEM and ODM models, while modular architecture allows rapid configuration across SKUs.

Engineering Services and Manufacturing Support

At HILPCB, we offer full-stack support for Smart TV PCB development, including early-stage simulation and post-assembly validation.

Comprehensive Services Include:

- Signal simulation using impedance calculator

- Visual validation via Gerber viewer

- Component planning with BOM viewer

- Functional and stress testing with production-grade diagnostics

All production complies with IPC-A-610 and RoHS standards, with traceable lot control and anti-counterfeit component sourcing.

Frequently Asked Questions About Smart TV PCB

Q: What are the key differences between Smart TV PCB and traditional television circuit boards? A: Smart TV PCBs integrate sophisticated computing platforms, wireless connectivity modules, and advanced video processing capabilities not found in traditional televisions. They require higher-performance processors, more complex power management, and additional interfaces for streaming services and smart features. Modern Smart TV main boards often feature ARM-based processors with dedicated graphics acceleration and substantial memory resources.

Q: How do you manage thermal challenges in Smart TV PCB design? A: Thermal management combines strategic component placement, thermal via implementation, and specialized substrate materials. High-power components like processors and LED drivers are positioned to maximize heat spreading while thermal vias conduct heat to chassis mounting points. Advanced designs may incorporate dedicated heat sinks or thermal interface materials for critical components.

Q: What testing procedures ensure Smart TV PCB reliability? A: Comprehensive testing includes electrical validation of all interfaces, thermal cycling from -20°C to +70°C, humidity exposure testing, and vibration resistance verification. Automated optical inspection validates assembly quality while in-circuit testing confirms component functionality. System-level testing validates complete television functionality including video processing, audio output, and connectivity features.

Q: Can you support both standard and premium Smart TV requirements? A: Yes, our capabilities span from basic Smart TV implementations with essential streaming features to premium systems supporting 8K displays, advanced HDR processing, and sophisticated audio systems. Manufacturing processes accommodate cost-optimized designs for mainstream markets and high-performance solutions for premium television segments while maintaining appropriate quality standards for each application.