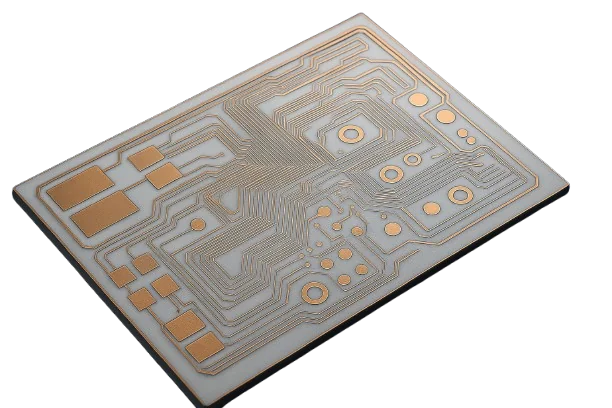

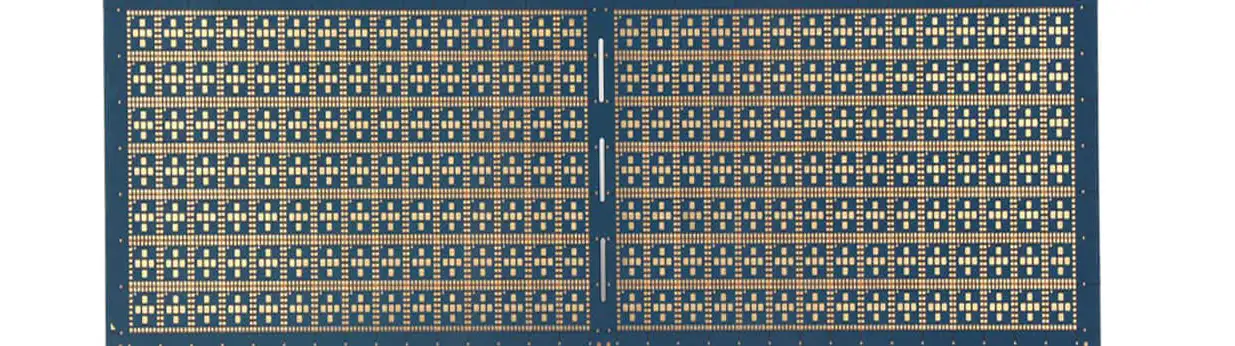

IC Substrate PCB (ABF/BT) | Fine-Line SAP, Stacked Microvias, 0.25–0.40 mm (zero point two five to zero point four zero) Pitch

Organic IC substrates for advanced packaging: Semi-Additive Process (SAP) 15–20 μm (fifteen to twenty micrometers) line/space, stacked microvias 25–50 μm (twenty-five to fifty), ABF/BT build-up, flip-chip ready with controlled warpage and impedance ±5% (plus/minus five percent).

IC Substrate Manufacturing & Material Architecture

Bridging silicon I/O density with system-level reliabilityIC substrates merge semiconductor packaging and PCB technology to achieve near-silicon routing density. The Semi-Additive Process (SAP) deposits copper on a seed layer to form fine features, delivering 15–20 μm (fifteen to twenty micrometers) line/space with minimal undercut—typically a 2–4× (two to four times) density gain compared to subtractive HDI. See our HDI PCB overview and advanced HDI manufacturing notes for related build-up concepts.

ABF (Ajinomoto Build-up Film) layers of 30–60 μm (thirty to sixty micrometers) maintain tight thickness control to stabilize impedance and PDN loop inductance.

BT resin composites typically show X-Y CTE of 12–14 ppm/°C (twelve to fourteen parts per million per degree Celsius), bridging silicon ~2.6 ppm/°C (two point six) and FR-4 ~16–18 ppm/°C (sixteen to eighteen). For mixed RF/digital layouts, material choices align with our high-frequency PCB guidance and materials primer.

Critical Risk: Mis-registration between ABF layers, poor copper adhesion, or uncontrolled warpage during lamination can lead to open circuits, via cracking, or impedance drift > ±10 percent (plus/minus ten percent). Inadequate via-in-pad filling and surface planarity also compromise wire-bonding reliability in SiP and flip-chip assemblies.

Our Solution: We apply signal integrity simulation and backplane PCB correlation methods to validate high-density interconnect behavior. SAP and mSAP lines operate in class 1000 cleanrooms with step-coverage control below ±2 μm (plus/minus two micrometers). Each substrate lot undergoes CTE mapping, warpage profiling, and TMA verification to IPC-6012 Class 3 AABUS requirements. Where RF front-ends demand ultra-low-loss performance, hybrid ABF and PTFE systems are co-processed to minimize dielectric discontinuity.

For further insight into material trade-offs and reliability modeling, review thermal stress validation and ceramic substrate PCB options that extend IC substrate technology into high-power RF and sensor applications.

- Fine-line routing via SAP with reduced undercut vs. subtractive etch

- ABF build-up 30–60 μm (thirty to sixty) dielectric control

- Composite CTE optimization (substrate target 9–14 ppm/°C — nine to fourteen)

- Warpage control ≤0.5% (less than or equal to zero point five percent) of diagonal (process target)

- Impedance stability with ±5% (plus/minus five percent) tolerance

🚀 快速报价请求

🔧 获取完整制造能力

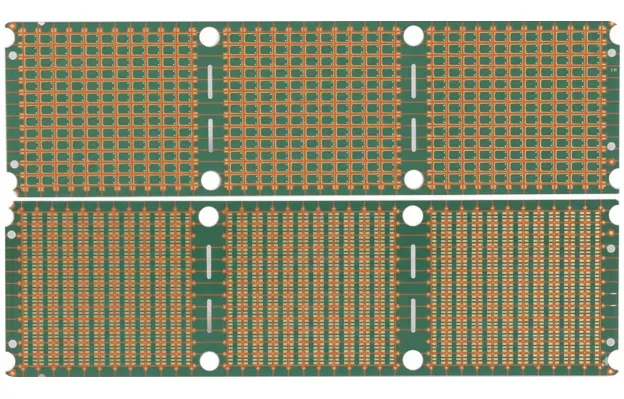

Controlled SAP Flow & Yield-Driven Quality Gates

Photolithography, plating and metrology tuned for fine pitchProcess windows are significantly tighter than standard PCB. Seed-layer deposition uniformity within ±10% (plus/minus ten percent) precedes photo patterning for 15–20 μm features. Pulse-reverse plating manages edge growth and throwing power; differential etch removes seed between traces with width control ±10% (plus/minus ten percent). Microvias at 25–50 μm (twenty-five to fifty micrometers) diameter achieve depth control ±5 μm (plus/minus five). See manufacturing excellence and HDI process controls.

AOI at ≤5 μm (less than or equal to five micrometers) resolution, X-ray registration targets, and IST (Interconnect Stress Test) over 200–500 (two hundred to five hundred) cycles protect reliability. For board-level integration (backplanes/line cards), see backplane PCB and high-speed PCB capabilities.

- Seed-layer thickness and uniformity SPC

- Pulse-reverse copper plating for uniform features

- Laser microvia formation and copper fill verification

- AOI/X-ray/IST multi-gate quality control

IC Substrate Technical Specifications

Fine-line, stacked microvias, and flip-chip compatible build-ups

| Parameter | Standard Capability | Advanced Capability | Standard |

|---|---|---|---|

Layer Count | 4–16 layers (four to sixteen) | Up to 50 layers (up to fifty) | JEDEC |

Base Materials | BT resin, High-Tg FR-4 | ABF, Polyimide, Glass substrate | IPC-4101/4103 |

Board Thickness | 0.20–0.80 mm (zero point two zero to zero point eight zero) | Down to 0.10 mm (down to zero point one zero) | IPC-A-600 |

Copper Weight | 12–18 μm (twelve to eighteen micrometers) | 5–35 μm (five to thirty-five; SAP builds) | IPC-4562 |

Min Trace/Space | 25/25 μm (one/one mil; twenty-five by twenty-five) | 15/15 μm (0.6/0.6 mil; fifteen by fifteen) | IPC-2226 |

Min Hole Size (Laser) | 50 μm (two mils) | 25 μm (one mil) | IPC-2226 |

Via Technology | Microvias, buried vias | Stacked microvias, via-in-pad, any-layer HDI | IPC-6012 |

BGA Pitch | 0.40 mm (zero point four zero) | 0.25 mm (zero point two five) | JEDEC |

Impedance Control | ±10% (plus/minus ten percent) | ±5% (plus/minus five percent) with TDR | IPC-2141 |

Surface Finish | ENIG, OSP | ENEPIG, Electroless Ni/Au, Soft/Hard Gold | IPC-4552/4556 |

Quality Testing | AOI, E-test | SEM, Cross-section, TDR/IST | IPC-9252 |

Certifications | ISO 9001, UL | IATF 16949, JEDEC methods | Industry standards |

Lead Time | 15–25 days (fifteen to twenty-five) | Consult for expedite | Production schedule |

准备开始您的PCB项目了吗?

无论您需要简单的原型还是复杂的生产运行,我们先进的制造能力确保卓越的质量和可靠性。30分钟内获取您的报价。

Signal Integrity & PDN Co-Design

At 28–112 Gbps (twenty-eight to one hundred twelve) SerDes, discontinuities at ball-to-substrate transitions dominate loss and reflections. Antipad tuning and ground-via fences within 0.5–1.0 mm (zero point five to one point zero millimeters) maintain return paths. Material Df selection (typical ABF 0.010–0.015 at 10 GHz) and copper roughness (Ra ≤1.5 μm) support insertion-loss targets—see impedance control and TDR testing.

PDN targets below 1–10 mΩ (one to ten milliohms) at up to 100 MHz (one hundred megahertz) rely on thin dielectrics 30–60 μm (thirty to sixty) and dense via farms under the die (typically 100–200 vias/cm²). For board-level channels and connectors, align with our high-speed PCB and backplane PCB capabilities.

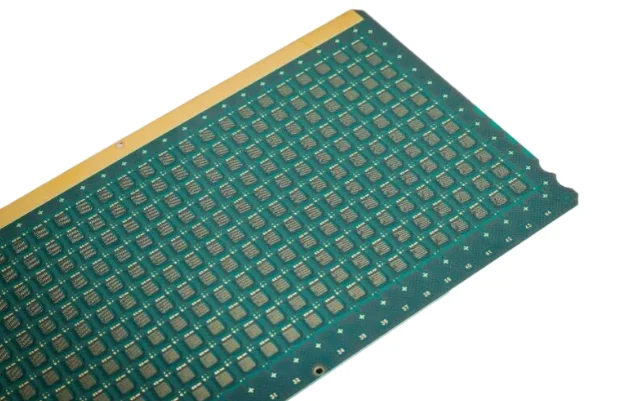

Registration Accuracy & Cleanroom Process Discipline

SAP starts with micro-roughening (Ra ~0.5–1.0 μm), seed copper 0.5–1.0 μm (zero point five to one point zero) and resist thickness 15–25 μm for 15–20 μm patterns. Pulse-reverse plating builds signal copper 10–15 μm (ten to fifteen) and planes 20–30 μm (twenty to thirty). After resist strip, differential etch clears seed without undercut. Cleanrooms (Class 1,000–10,000 — one thousand to ten thousand) minimize shorts/opens in fine pitch; see manufacturing flow.

Layer-to-layer registration targets ±25 μm (plus/minus twenty-five micrometers) using optical alignment and X-ray fiducials. Sequential build-up uses low-flow systems (resin flow <5% — less than five percent) to hold dielectric thickness ±5% (plus/minus five percent). SPC maintains Cpk ≥1.33 (greater than or equal to one point three three) for critical features.

ABF vs. BT vs. Glass & Emerging Options

ABF: photoimageable, microvia by lithography to 15–25 μm (fifteen to twenty-five), Dk ~3.2–3.4, Df ~0.010–0.015 at 10 GHz.

BT: cost-effective for wire-bond/moderate flip-chip with X-Y CTE 12–14 ppm/°C.

Glass substrate: CTE ~3 ppm/°C and ultra-smooth Ra <0.1 μm (less than zero point one), enabling TGV/bridge structures. For RF front-end modules, also consider ceramic PCB interposers.

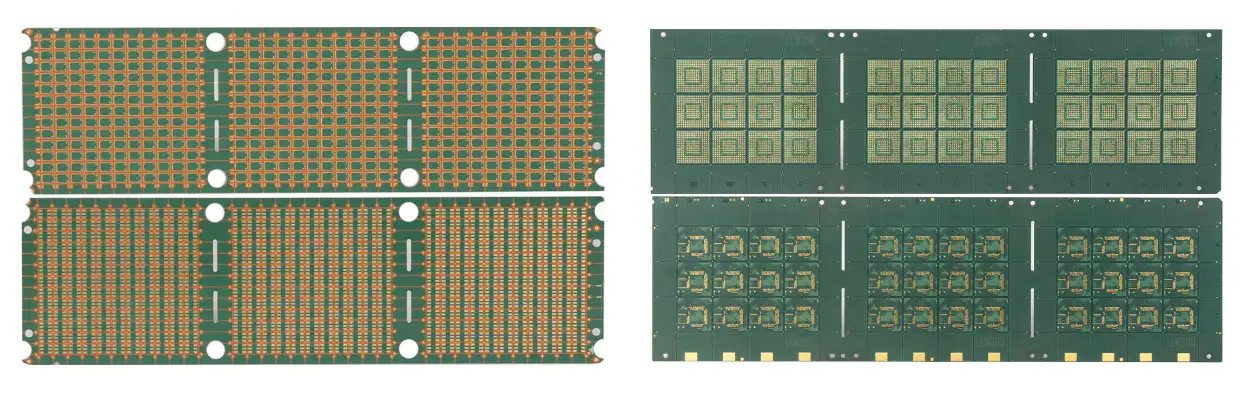

Flip-Chip, Underfill & PoP Assembly

Flip-chip requires coplanarity control; warpage exceeding 50–75 μm (fifty to seventy-five micrometers) risks non-wet joints. Underfill with CTE 25–35 ppm/°C redistributes stress. For PoP and SiP, coordinate pitch/warpage and reflow profiles. Explore packaging notes in flip-chip substrate and system validation in box build.

Engineering Assurance & Certifications

Experience: volume SAP builds with 15–20 μm routing and 0.25–0.40 mm pitches.

Expertise: seed uniformity, pulse-reverse plating, stacked microvia fill and X-ray registration; SPC keeps Cpk ≥1.33 (greater than or equal to one point three three).

Authoritativeness: JEDEC-aligned reliability, IPC-6012 Class 3 documentation.

Trustworthiness: MES traceability linking supplier lots, serialization and AOI/X-ray/IST/TDR reports.

- Controls: thickness mapping, etch factor, registration, copper roughness

- Traceability: lot codes, unit serialization, digital traveler

- Validation: IST 200–500 cycles, cross-sections, SIR, TDR

常见问题

ABF vs. BT: which dielectric should I choose?

What fine-line and via sizes do you support?

How do you manage warpage for flip-chip?

Can the substrate handle 112 Gbps channels?

Which surface finish is recommended?

体验先进的PCB制造卓越

从简单的原型到复杂的生产运行,我们的世界级工厂提供卓越的质量、快速的周转和有竞争力的价格。加入数千名信任我们PCB制造需求的满意客户。