Highleap PCB Factory (HILPCB) delivers cutting-edge ADAS PCB manufacturing and assembly solutions designed for advanced driver assistance systems and autonomous vehicle applications. Our precision manufacturing processes combine high-reliability fabrication, safety-critical assembly techniques, and automotive-grade quality systems to produce superior ADAS PCBs for mission-critical automotive safety applications.

Modern ADAS PCB designs require sophisticated integration of sensor interfaces, high-speed processing units, and safety-critical communication protocols while maintaining stringent automotive reliability standards. Our ADAS-grade manufacturing and assembly ensures compliance with ISO 26262 functional safety, ISO/TS 16949, and AEC-Q100 standards for reliable operation in safety-critical autonomous driving systems.

ADAS PCB Design Excellence and Sensor Integration

ADAS PCB design demands sophisticated integration of multiple sensor technologies, high-performance processing units, and safety-critical communication interfaces. HILPCB implements advanced layout optimization, signal integrity techniques, and electromagnetic compatibility solutions ensuring reliable sensor data processing and autonomous system performance.

Core ADAS Technologies:

• Multi-Sensor Integration: Strategic design accommodates radar sensors, LiDAR interfaces, camera modules, and ultrasonic sensors while maintaining signal integrity through optimized routing and controlled impedance design

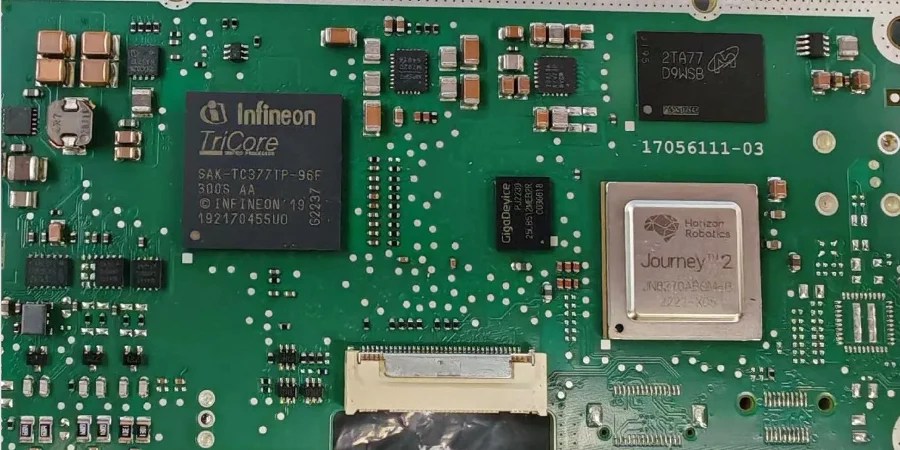

• High-Speed Processing: Advanced microprocessor and GPU integration with optimized power delivery networks, thermal management, and high-speed digital signal routing for real-time sensor data processing

• Safety-Critical Communication: CAN-FD, Ethernet AVB, and FlexRay protocol support enables reliable vehicle network communication while meeting ISO 26262 functional safety requirements

• Electromagnetic Compatibility: Advanced EMC design techniques minimize interference between sensor circuits and ensure compliance with automotive EMC standards for reliable operation in electromagnetic environments

Our ADAS designs utilize specialized high-frequency PCB techniques for radar and communication signals while multilayer PCB configurations provide optimal power distribution and signal isolation for sensitive sensor circuits.

Advanced ADAS PCB Assembly and Manufacturing Processes

ADAS PCB assembly at HILPCB combines automotive-qualified materials with precision manufacturing processes and safety-critical assembly techniques. Our integrated approach encompasses PCB fabrication through comprehensive functional testing, ensuring ADAS systems meet stringent automotive safety requirements.

Precision Material Systems: Safety-critical substrates including low-loss dielectrics, high thermal PCB laminates, and automotive-grade materials provide enhanced reliability for ADAS applications operating from -40°C to +85°C with long-term stability requirements.

Advanced Assembly Techniques: SMT assembly capabilities include ultra-fine pitch component placement for advanced processors, memory devices, and sensor interface circuits using high-precision pick-and-place equipment with advanced vision systems ensuring accurate component placement and orientation verification.

Safety-Critical Component Integration: Specialized assembly processes handle high-pin-count processors, memory modules, sensor connectors, and safety-critical components with automated insertion equipment, precision torque control, and comprehensive traceability documentation meeting ISO 26262 requirements.

Thermal Management and Safety-Critical Assembly Testing

ADAS PCBs process intensive sensor data requiring sophisticated thermal management strategies and comprehensive safety validation. HILPCB implements advanced thermal design techniques and extensive testing protocols ensuring optimal performance and safety compliance throughout automotive lifecycles.

Strategic thermal management includes optimized copper pour design, thermal via implementation, and heat spreading techniques distributing thermal loads across PCB structures. Metal core PCB configurations provide enhanced thermal conductivity for high-power processing units and sensor interface circuits.

Comprehensive Assembly Validation: Safety-critical testing includes in-circuit testing (ICT) for electrical verification, boundary scan testing for digital circuits, and functional testing with actual sensor interfaces. Advanced X-ray inspection validates critical solder joints in BGA packages and fine-pitch components essential for ADAS reliability.

Environmental testing encompasses thermal cycling, vibration testing, and humidity exposure evaluation per automotive standards. Accelerated life testing and statistical analysis validate long-term reliability while ensuring consistent ADAS performance throughout vehicle operational life under safety-critical conditions.

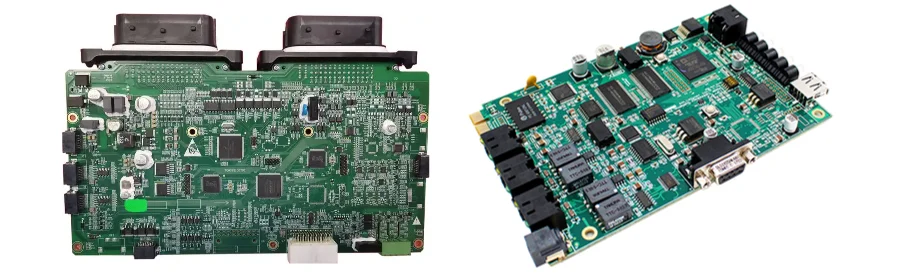

Complete ADAS Assembly Solutions and HDI Integration

Modern ADAS PCB assembly supports diverse sensor technologies from basic parking assistance to full autonomous driving systems. HDI PCB assembly technologies enable ultra-compact designs with high-density component integration supporting advanced sensor fusion and real-time processing capabilities.

Complete Assembly Services:

- Sensor interface integration and calibration

- High-performance processor assembly and testing

- Memory module installation and validation

- Communication interface assembly and verification

- Power management system integration

- Software programming and functional validation

Rigid-flex PCB assembly accommodates complex ADAS geometries while maintaining signal integrity under mechanical stress. Specialized assembly techniques handle flexible sections, sensor cable connections, and multi-board interconnections typical of distributed ADAS architectures.

Turnkey Assembly Integration: Complete ADAS solutions include component sourcing with authentic part verification, inventory management, assembly scheduling, and comprehensive testing protocols. Our turnkey approach encompasses PCB fabrication, component procurement, assembly, validation testing, and packaging for direct integration into automotive ADAS production lines.

Professional ADAS PCB Manufacturing and Assembly Services

Highleap PCB Factory delivers comprehensive ADAS PCB manufacturing and assembly services with specialized equipment and safety-critical qualified processes. ISO 26262 functional safety compliance and ISO/TS 16949 certification ensure consistent quality while PPAP documentation provides complete manufacturing and assembly traceability for automotive safety programs.

Our integrated manufacturing and assembly capabilities include controlled impedance fabrication for high-speed signals, precision component placement for ultra-fine pitch packages, and specialized assembly processes for sensor connectors and safety-critical interfaces. Small batch assembly services support prototype and validation requirements while large volume assembly capabilities scale to automotive production demands.

Quality assurance protocols encompass automated optical inspection, flying probe testing, functional verification with sensor simulation, and environmental stress screening validating complete ADAS assembly performance under automotive operating conditions with comprehensive documentation supporting automotive safety qualification requirements.

Advanced traceability systems track every component, assembly process, and test result throughout the manufacturing lifecycle, providing complete genealogy records essential for safety-critical automotive applications and regulatory compliance requirements.

Frequently Asked Questions About ADAS PCB

Q: What makes ADAS PCB different from standard automotive PCBs? A: ADAS PCBs require safety-critical design per ISO 26262, advanced sensor integration capabilities, high-speed processing support, enhanced EMC performance, specialized thermal management for intensive computing, and comprehensive traceability throughout manufacturing and assembly processes.

Q: What sensor technologies can your ADAS PCB assembly support? A: Our ADAS PCB assembly services support radar sensors, LiDAR interfaces, camera modules, ultrasonic sensors, IMU devices, and GPS modules with complete integration including sensor interface circuits, power management, signal conditioning, and functional testing with actual sensor components.

Q: How do you ensure ADAS PCB assembly meets functional safety requirements? A: We maintain ISO 26262 functional safety compliance, implement comprehensive component traceability, conduct extensive validation testing, utilize redundant safety circuits, perform failure mode analysis, and provide complete documentation supporting automotive safety qualification requirements.

Q: What is the typical lead time for ADAS PCB manufacturing and assembly? A: Standard ADAS PCB with assembly lead times range from 18-25 days for prototype quantities and 25-35 days for production volumes, depending on layer count, component complexity, sensor integration requirements, and safety validation testing specifications. Expedited services available for urgent development programs.

Q: Can you provide complete turnkey ADAS assembly including sensor calibration and testing? A: Yes, HILPCB offers comprehensive turnkey ADAS assembly services including component sourcing with authentic part verification, SMT and specialized assembly, sensor interface integration, system calibration, functional testing with sensor simulation, environmental validation, and complete ISO 26262 documentation for automotive ADAS applications.