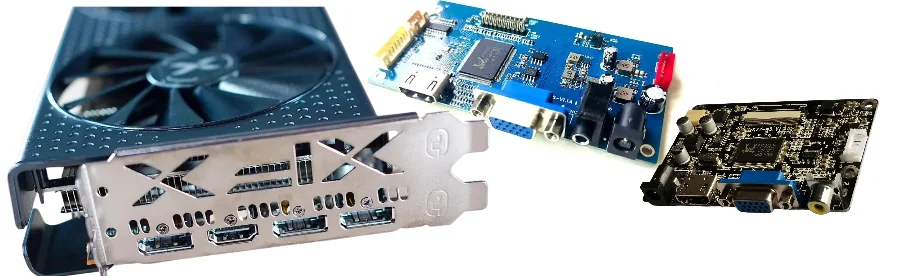

HILPCB is a full-service PCB manufacturer with advanced capabilities in high-frequency, HDI, and multilayer circuit board production. Our manufacturing and assembly solutions support a wide range of advanced applications, including HDMI PCBs for consumer electronics, professional broadcast equipment, automotive infotainment systems, and industrial display applications.

Beyond manufacturing, we provide end-to-end PCB assembly services, including precision SMT mounting for HDMI controllers, BGA assembly, fine-pitch component placement, and comprehensive testing with X-ray/AOI inspection, ensuring optimal signal integrity and long-term performance for high-speed digital transmission systems.

While our services span many industries beyond digital AV, our processes are perfectly suited for HDMI PCB assembly, high-definition multimedia systems, and other designs requiring precise impedance control, signal integrity optimization, and reliable high-speed data transmission. From prototype to volume production, HILPCB ensures high-quality PCB delivery through consistent performance and rigorous process control.

Advanced HDMI PCB Design and Manufacturing Capabilities

Designing and producing HDMI circuit boards requires deep expertise in signal integrity, impedance control, and high-frequency PCB design. Our solutions support:

High-Speed TMDS Signal Processing

Optimized for HDMI 2.1 specifications, we manufacture PCBs with controlled impedance traces, precision differential pairs, and advanced stackup designs that maintain signal integrity across all data rates up to 48 Gbps.Multilayer and HDI PCB Structures

Our HDMI PCB stackups feature impedance-controlled routing, microvias, and thermally stable dielectric materials, ideal for compact designs and high-density component integration.Professional Broadcast HDMI Applications

From studio equipment to live production systems, we manufacture ruggedized PCBs meeting broadcast industry standards, capable of withstanding continuous operation and electromagnetic interference.Thermal Management Integration

Advanced thermal design techniques including thermal vias, copper pour optimization, and strategic component placement ensure stable operation under high-power conditions and extended operational cycles.

We also support hybrid digital systems, including designs that combine HDMI with other high-speed interfaces like USB-C, DisplayPort, and proprietary digital protocols for comprehensive multimedia solutions.

Advanced HDMI PCB Manufacturing and Testing Processes

Our manufacturing workflow is optimized for HDMI PCB assembly, where signal integrity and electrical performance are critical:

Controlled Material Selection

We utilize high-frequency PCB materials with consistent dielectric properties, low loss tangent, and stable impedance characteristics across the entire frequency spectrum required for HDMI 2.1 applications.Precision SMT and Component Assembly

Using ultra-fine pitch SMT processes, we assemble precision HDMI controllers and supporting components with placement accuracy better than 25 microns, ensuring optimal electrical performance and reliability.Comprehensive Testing and Validation

All HDMI PCBs undergo rigorous testing including impedance verification, insertion loss measurement, crosstalk analysis, and eye diagram validation to ensure compliance with HDMI specifications.Environmental Stress Screening

We simulate extreme conditions through temperature cycling (-40°C to +85°C), vibration testing, and humidity exposure to validate performance for automotive, industrial, and professional broadcast applications.EMC Compliance and Certification

Our HDMI PCBs meet stringent electromagnetic compatibility standards including FCC Part 15, CE marking requirements, and automotive EMC specifications for global deployment.

HDMI PCB Applications Across Industries

We manufacture high-performance HDMI PCBs for diverse applications across multiple industries:

Consumer Electronics Systems

Smart TVs, set-top boxes, gaming consoles, media streaming devices, smartphone displays, tablet interfaces, and home theater receivers with advanced HDMI connectivity.Professional Broadcast Equipment

Studio cameras, video mixers, broadcast monitors, live production switchers, digital signage controllers, and professional recording equipment requiring uncompromised signal quality.Automotive Infotainment Systems

In-vehicle displays, rear-seat entertainment systems, dashboard multimedia interfaces, backup camera systems, and autonomous vehicle display integration with high-speed PCB technology.Industrial Display Applications

Machine operator interfaces, process control displays, industrial automation systems, factory floor monitoring equipment, and ruggedized display solutions for harsh environments.Medical Imaging Equipment

Diagnostic display systems, surgical monitors, patient monitoring interfaces, telemedicine platforms, and medical imaging workstations requiring precise color reproduction.Security and Surveillance Systems

Digital video recorders, network video servers, security monitors, IP camera systems, and access control displays with integrated HDMI output capabilities.Educational Technology Platforms

Interactive whiteboards, classroom display systems, distance learning equipment, presentation systems, and educational multimedia platforms.Aerospace and Defense Electronics

Ruggedized display systems, cockpit interfaces, ground control displays, mission-critical monitoring equipment, and defense communication systems with Rogers PCB materials.Digital Signage and Advertising

Large format displays, outdoor advertising systems, retail digital signage, transportation information displays, and interactive kiosk interfaces.Gaming and Entertainment Systems

Professional gaming equipment, arcade systems, casino gaming machines, virtual reality displays, and high-performance gaming peripherals.

We support custom HDMI PCB development for all applications, balancing performance requirements, cost constraints, and reliability expectations across mission-critical, commercial, and emerging technology implementations.

Why Choose HILPCB as Your HDMI PCB Manufacturing Partner

We go beyond standard PCB production to provide comprehensive support for your HDMI and digital multimedia development:

Specialized High-Speed Design Expertise

Advanced routing techniques, signal isolation strategies, and impedance optimization ensure optimal HDMI signal integrity and long-term electrical stability with impedance calculator verification.Professional-Grade Manufacturing Standards

IPC Class 3, ISO 9001, and AS9100-based systems ensure complete traceability and industry-leading quality for professional broadcast and automotive applications.Flexible Prototyping and Scalable Production

From initial development to long-term manufacturing, we support flexible batch sizes and on-time delivery to meet aggressive project schedules and market demands.Expert Engineering Support

Signal integrity simulation, HDMI compliance consulting, and EMC analysis services optimize multimedia system PCB performance and regulatory compliance.Complete Lifecycle Services

Including material procurement, SMT assembly, testing, design updates, and obsolescence management for long-term HDMI system success.

HDMI PCB Frequently Asked Questions

What is an HDMI PCB?

An HDMI PCB is a specialized circuit board designed to handle high-speed digital audio and video signals according to HDMI specifications. It integrates differential signal pairs, impedance control, and supporting circuitry to enable reliable transmission of uncompressed multimedia data.

Can HILPCB support professional broadcast HDMI applications?

Yes. We meet professional broadcast standards including extended temperature ranges, enhanced EMC compliance, and ruggedized construction suitable for studio environments and live production systems.

What makes HDMI 2.1 PCBs different from earlier versions?

HDMI 2.1 PCBs require enhanced signal integrity design to support data rates up to 48 Gbps. This demands tighter impedance control, advanced materials, and more sophisticated stackup designs compared to earlier HDMI versions.

Do you manufacture integrated HDMI controller PCBs?

Yes. We produce compact HDMI PCB assemblies with integrated controllers, supporting components, and connector systems suitable for consumer electronics, automotive applications, and professional equipment.

Can I order both prototypes and production volumes?

Absolutely. We support complete lifecycle manufacturing from initial design validation to high-volume HDMI PCB production with consistent quality and delivery schedules.

What testing do you perform on HDMI PCBs?

Our comprehensive testing includes impedance measurement, insertion loss analysis, crosstalk verification, eye diagram validation, and HDMI compliance testing to ensure optimal performance and specification adherence.

Do you support automotive-grade HDMI PCBs?

Yes. We manufacture automotive-qualified HDMI PCBs meeting AEC-Q100 standards with enhanced temperature cycling, vibration resistance, and long-term reliability for infotainment applications.