Quality failures in PCB manufacturing can cascade through entire production lines, causing delays, rework, and customer dissatisfaction that extends far beyond the initial defect. IPC-6012 PCB quality standards establish comprehensive qualification and performance requirements for rigid printed circuit boards, defining the testing procedures, acceptance criteria, and quality levels that ensure consistent manufacturing excellence. These standards provide the framework for evaluating PCB performance across electrical, mechanical, and environmental parameters, enabling manufacturers to deliver reliable products that meet demanding application requirements.

HILPCB manufactures rigid PCBs in full compliance with IPC-6012 standards, implementing comprehensive testing protocols and quality management systems that ensure every board meets the specified performance requirements. Our quality assurance processes validate adherence to IPC-6012 criteria throughout manufacturing, providing customers with documented performance verification and long-term reliability assurance.

IPC-6012 PCB Standard Structure and Performance Classifications

IPC-6012 establishes a comprehensive framework for evaluating rigid PCB quality through systematic testing and qualification procedures that address all critical performance parameters. The standard defines clear criteria for electrical, mechanical, and environmental performance that ensure PCBs meet their intended application requirements.

The core structure of IPC-6012 PCB standards includes:

- Performance class definitions ranging from general purpose to high-reliability applications

- Comprehensive test methodologies for electrical, mechanical, and environmental validation

- Acceptance criteria for FR4 PCB and specialized substrate materials

- Quality conformance requirements including statistical sampling and documentation

- Single-double layer PCB through complex multilayer board specifications

- Qualification procedures for rigid-flex PCB transitional areas and flexible sections

IPC-6012 PCB performance classes provide scalable quality requirements that match application needs with appropriate testing rigor. Class 1 addresses general electronic products with standard reliability requirements, while Class 2 covers dedicated service applications requiring enhanced performance. Class 3 defines high-performance requirements for applications demanding maximum reliability and extended operational life.

The standard incorporates requirements for HDI PCB technologies including microvia reliability, sequential lamination quality, and fine-line conductor performance that address the unique challenges of high-density interconnect manufacturing.

Comprehensive Testing Requirements and Qualification Procedures

IPC-6012 PCB standards establish rigorous testing protocols that validate PCB performance across multiple domains, ensuring comprehensive quality assessment before product release.

Electrical Testing Requirements

The standard defines extensive electrical testing procedures that validate PCB performance under various operating conditions:

1. Conductor Resistance and Current Carrying Capacity

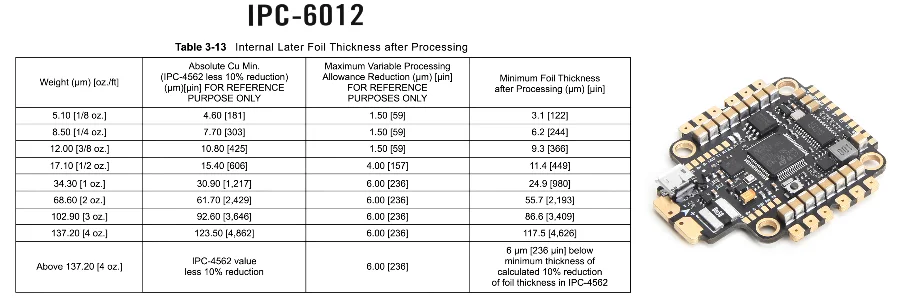

IPC-6012 specifies resistance measurement procedures for conductors of different widths and thicknesses, ensuring consistency with design calculations. Current carrying capacity testing validates thermal performance under specified load conditions, confirming that conductors can handle design currents without exceeding temperature limits.

- Resistance Measurement Protocols: Standardized test methods for conductor resistance validation

- Thermal Performance Testing: Current loading tests with temperature monitoring

- Long-term Stability: Extended duration testing for thermal cycling effects

2. Insulation Resistance and Dielectric Strength

Critical electrical isolation properties are validated through comprehensive insulation resistance testing and dielectric breakdown voltage measurements. These tests ensure adequate electrical isolation between conductors and layers throughout the board's operational lifetime.

- Insulation Resistance Testing: Measurements between conductors at various voltages and environmental conditions

- Dielectric Strength Validation: Breakdown voltage testing to ensure safety margins

- Environmental Conditioning: Testing under elevated temperature and humidity conditions

3. Impedance Control Verification

For high-speed PCB applications requiring controlled impedance, IPC-6012 establishes testing procedures that validate impedance accuracy and consistency across production lots.

Mechanical and Environmental Testing Standards in IPC-6012 PCB

Mechanical reliability represents a critical aspect of PCB performance, particularly for applications subjected to thermal cycling, vibration, and mechanical stress. IPC-6012 establishes comprehensive mechanical testing procedures that validate long-term reliability under realistic operating conditions.

Thermal Cycling and Shock Testing Requirements

Thermal stress represents one of the primary failure mechanisms in PCB applications, making thermal testing a cornerstone of IPC-6012 qualification procedures.

- Thermal Cycling Parameters The standard defines specific thermal cycling profiles with controlled ramp rates, dwell times, and temperature extremes that simulate years of operational thermal stress in accelerated timeframes.

- Thermal Shock Testing Rapid temperature transitions validate PCB performance under sudden thermal changes that could occur during operation or assembly processes.

- Coefficient of Thermal Expansion (CTE) Matching Testing validates CTE compatibility between substrate materials and copper conductors to minimize stress concentration and prevent delamination.

- Post-Thermal Testing Requirements Electrical and mechanical testing following thermal exposure ensures performance degradation remains within acceptable limits.

Mechanical Stress and Vibration Testing

IPC-6012 addresses mechanical reliability through comprehensive testing that simulates various forms of mechanical stress encountered in real-world applications.

- Flexural Strength Testing Mechanical bending tests validate substrate strength and determine failure modes under mechanical stress.

- Peel Strength Validation Copper adhesion testing ensures reliable conductor attachment under mechanical and thermal stress conditions.

- Via Reliability Assessment Mechanical stress testing of via connections validates interconnection reliability under thermal and mechanical cycling.

- Halogen-Free PCB Considerations Special testing requirements for halogen-free materials that may exhibit different mechanical properties compared to standard substrates.

Environmental Exposure Testing

Environmental testing validates PCB performance under various atmospheric and chemical exposure conditions that could be encountered during operation or storage.

- Humidity Resistance Testing Extended exposure to controlled humidity conditions validates moisture absorption effects and long-term electrical performance.

- Salt Spray Exposure Corrosion resistance testing ensures adequate protection against environmental contamination and chemical exposure.

- Chemical Compatibility Testing validates resistance to cleaning agents, flux residues, and other chemicals encountered during assembly and operation.

- UV Exposure Testing For applications with potential UV exposure, testing validates material stability and performance degradation under ultraviolet radiation.

IPC-6012 PCB Performance Classes and Application Guidelines

IPC-6012 defines three distinct performance classes that enable appropriate quality levels for different application requirements while maintaining cost-effectiveness and manufacturing efficiency.

Class 1 - General Electronic Products: Designed for applications where cosmetic imperfections are acceptable and the primary requirement is function rather than extended life. Class 1 testing provides basic performance validation suitable for consumer electronics and general-purpose applications with standard reliability expectations.

Class 2 - Dedicated Service Electronic Products: Addresses applications requiring higher performance and reliability where extended service life is important but not critical. Class 2 testing includes enhanced thermal cycling, improved electrical testing, and additional environmental validation suitable for industrial equipment and professional electronics.

Class 3 - High Performance Electronic Products: Defines the highest performance requirements for applications where continuous operation is essential and product failure could result in significant consequences. Class 3 testing incorporates the most rigorous thermal, mechanical, and environmental testing protocols suitable for aerospace, defense, and life-critical applications.

Application selection guidelines help manufacturers choose appropriate performance classes based on operating environment, reliability requirements, and cost considerations. The standard provides decision matrices that consider factors including operating temperature range, expected service life, environmental exposure, and failure consequence severity.

Integrated Quality Management for IPC-6012 PCB Compliance

Beyond core testing requirements, IPC-6012 establishes quality management principles that ensure consistent performance across production lots and manufacturing locations.

Statistical Sampling and Quality Control:

- Lot acceptance sampling procedures based on statistical confidence levels

- Quality trend monitoring and control chart implementation

- Corrective action protocols for out-of-specification results

- Documentation requirements for traceability and quality investigation

Advanced Manufacturing Process Control:

- In-process monitoring of critical parameters affecting final performance

- Statistical process control implementation for key manufacturing variables

- Capability studies demonstrating process consistency and control

- Continuous improvement programs based on quality data analysis

Supplier Qualification and Material Control:

- Material qualification procedures ensuring substrate and component compatibility

- Incoming inspection protocols for critical materials and components

- Supplier quality management and performance monitoring

- Small batch assembly validation for process qualification and optimization

Why Choose HILPCB for IPC-6012 PCB Manufacturing

Achieving consistent IPC-6012 compliance requires sophisticated manufacturing processes, comprehensive testing capabilities, and robust quality management systems. HILPCB combines advanced manufacturing technology with rigorous quality control procedures, ensuring every PCB meets or exceeds IPC-6012 requirements for its designated performance class.

We maintain comprehensive testing laboratories with capabilities spanning electrical, mechanical, and environmental validation per IPC-6012 protocols. Our quality management systems incorporate statistical process control, capability analysis, and continuous improvement processes that ensure consistent performance across all production volumes from prototypes through high-volume manufacturing runs.

Our engineering teams provide IPC-6012 compliance consulting, helping customers select appropriate performance classes and optimize designs for reliable manufacturing. From material selection through final testing, we ensure complete adherence to IPC-6012 requirements while maintaining cost-effective production processes that support competitive product development.

Frequently Asked Questions — IPC-6012 PCB Standards

Q1: What is the main purpose of IPC-6012 PCB standards?

A: IPC-6012 establishes qualification and performance requirements for rigid printed circuit boards, defining testing procedures and acceptance criteria that ensure consistent quality and reliability across different performance classes.

Q2: How do I choose the appropriate IPC-6012 performance class?

A: Performance class selection depends on application requirements including operating environment, expected service life, reliability requirements, and failure consequence severity. Class 1 suits general applications, Class 2 addresses dedicated service needs, and Class 3 covers high-performance requirements.

Q3: What testing is required for IPC-6012 compliance?

A: IPC-6012 requires comprehensive electrical, mechanical, and environmental testing including conductor resistance, insulation resistance, thermal cycling, mechanical stress testing, and environmental exposure validation based on the selected performance class.

Q4: Does IPC-6012 apply to flexible PCBs?

A: IPC-6012 specifically addresses rigid printed circuit boards. Flex PCB applications are covered by IPC-6013, though rigid sections of rigid-flex designs fall under IPC-6012 requirements.

Q5: How often should IPC-6012 qualification testing be performed?

A: The standard defines qualification testing frequencies based on production volume, process changes, and material modifications. Periodic requalification ensures continued compliance and process stability.

Q6: What documentation is required for IPC-6012 compliance?

A: Complete documentation includes test procedures, acceptance criteria, statistical sampling plans, test results, and quality conformance certificates that demonstrate adherence to specified performance class requirements.