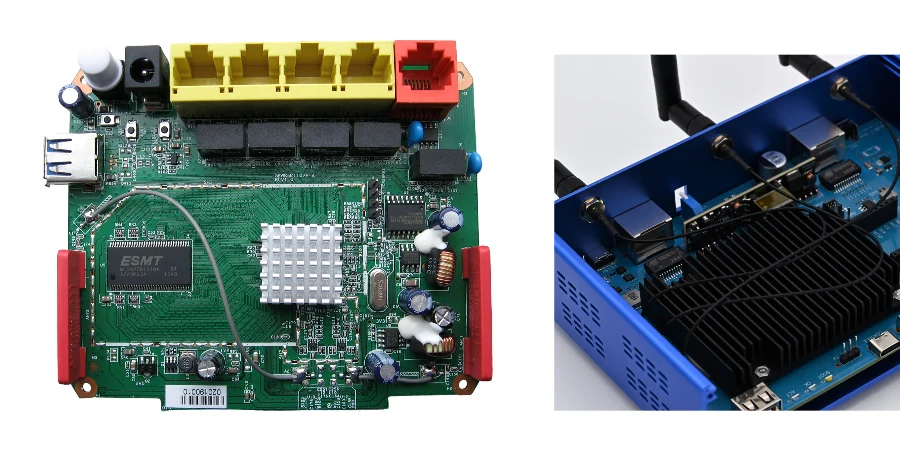

HILPCB provides advanced Router PCB solutions that combine high‑frequency design expertise with precision manufacturing and assembly. Our boards are engineered for reliable data transmission across consumer routers, enterprise switches, industrial networking devices, and next‑generation 5G infrastructure.

Modern Router PCBs integrate multi‑layer RF and digital routing, EMI shielding, and compact layouts to support multi‑gigabit throughput. Our expertise ranges from dual‑band WiFi 2.4/5 GHz boards to complex tri‑band and 5G systems with MIMO antennas, hardware acceleration, and advanced routing protocols.

Router PCB Design and Architecture

High‑performance Router PCB design requires precise signal integrity, multi‑layer routing, and EMI mitigation. Key elements include:

- RF Front-End: Multi‑band transceivers for 2.4/5/6 GHz WiFi with PA/LNA and antenna switching

- Digital Core: High‑speed processors with DDR4/DDR5 and dedicated packet buffers

- Power Delivery Network: Multi‑rail regulation, optimized decoupling, and thermal monitoring

- Controlled Impedance: 50 Ω single‑ended and 100 Ω differential pairs with minimal via stubs

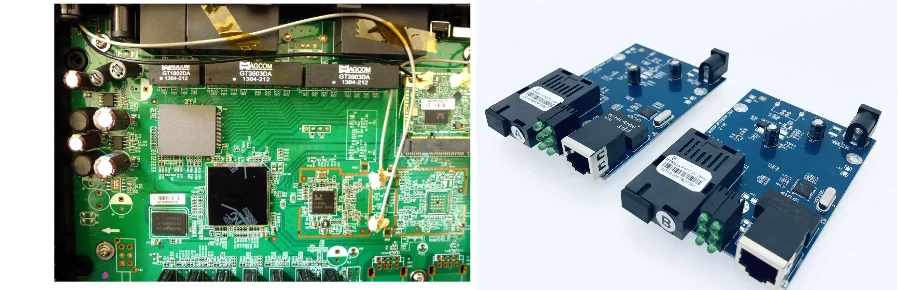

Advanced Router PCBs typically use 4‑12 layer stackups with dedicated power and ground planes, designed for minimal crosstalk and low‑loss high‑speed paths. For complex routing requirements, our multilayer PCB solutions provide the foundation for sophisticated network designs. Pre‑layout simulation and electromagnetic modeling ensure signal integrity and manufacturability for high‑frequency and gigabit Ethernet interfaces.

High-Frequency Router PCB Manufacturing

Manufacturing Router PCBs for enterprise and 5G applications requires strict process control to achieve high‑frequency reliability:

- Substrate Materials: Rogers RO4350B / RO4003C for low‑loss RF; high‑grade FR4 for cost‑sensitive 2.4 GHz designs

- Impedance Control: ±5% tolerance verified by TDR for RF and high‑speed Ethernet lines

- HDI and Via Technology: Laser‑drilled microvias, sequential lamination, and back‑drilling for high‑density routing

- Surface Finish: ENIG for solder reliability and stable RF performance

- Precision Assembly: 0.4 mm BGA, 01005 components, ±25 µm placement accuracy

For high-frequency applications requiring superior RF performance, our Rogers PCB manufacturing capabilities ensure optimal signal integrity and minimal loss. Additionally, our HDI PCB technology enables compact designs with exceptional routing density.

Thermal performance is enhanced by copper pours, thermal vias, and high‑conductivity laminates. Optimized PDN layout and decoupling strategies ensure stable power delivery under heavy network loads. All processes comply with volume manufacturing and assembly standards for consistent quality.

Router PCB Applications and Technology Integration

Consumer & IoT Routers:

Dual‑ and tri‑band WiFi (2.4/5/6 GHz), MIMO support, and multi‑protocol IoT connectivity (WiFi, Bluetooth, Zigbee, Thread) with low‑power standby operation and compact layouts.

Enterprise & Industrial Networking:

Router PCBs designed for reliability, security, and PoE+ up to 60 W per port. Industrial boards feature extended temperature tolerance, EMI immunity, conformal coating, and screened components for harsh environments.

5G & Edge Computing:

Millimeter‑wave Router PCBs with precision substrates enable multi‑gigabit throughput, low‑latency processing, and edge computing integration. Our high-frequency PCB solutions are specifically designed for these demanding 5G applications. Optimized thermal and PDN design ensures stable performance under heavy traffic.

Automotive & Transportation:

Router PCBs supporting cellular, V2X, and WiFi hotspot functions meet AEC‑Q100 and vibration standards. Railway, maritime, and aviation applications require specialized environmental and safety certifications.

Professional High‑Frequency & Complex Router PCB Manufacturing Services

At HILPCB, we provide high‑frequency, complex multi‑layer, and fine‑pitch PCB fabrication and assembly services for demanding networking and communication applications. While Router PCBs are a key application, our expertise spans a wide range of high‑performance boards for enterprise networking, 5G infrastructure, and industrial electronics.

Our core capabilities include:

- High‑Frequency PCB Manufacturing – Rogers, low‑loss laminates, and controlled impedance for RF and multi‑gigahertz designs

- Complex Multi‑Layer & HDI PCB – 4‑60+ layers, sequential lamination, microvias, and back‑drill technology

- Fine‑Pitch & High‑Precision Assembly – 0.4 mm BGA, 01005 SMT, and turnkey PCBA for compact designs

- Signal, Thermal & EMC Optimization – Ensuring stable performance for high‑speed and high‑power systems

- Certified Quality & Global Compliance – ISO 9001:2015, IPC Class 2/3, RoHS, REACH, and optional PPAP for automotive and telecom projects

For high-speed digital interfaces and data processing requirements, our high-speed PCB manufacturing ensures optimal signal integrity. Complete assembly services are available through our turnkey assembly solutions, providing end-to-end manufacturing support.

With HILPCB, you get a trusted PCB manufacturing partner that shortens your time‑to‑market, ensures production consistency, and supports high‑reliability applications. Whether you need Router PCBs, 5G communication boards, or complex RF modules

Frequently Asked Questions About Router PCB

Q: What makes router PCB design different from standard digital PCBs?

A: Router PCB design requires high-frequency RF capabilities for wireless operation, advanced multi-layer construction for complex signal routing, sophisticated EMI mitigation, and precise impedance control for gigabit Ethernet interfaces. Thermal management and power delivery are also critical for sustained high-performance operation.

Q: Which substrate materials are recommended for router PCB applications?

A: For high-performance applications, Rogers materials like RO4350B provide optimal RF performance with low loss tangent. Consumer applications can use high-quality FR4 for 2.4GHz operation, while 5GHz and 6GHz designs benefit from specialized low-loss substrates for optimal signal integrity.

Q: How do you ensure router PCB performance meets networking standards?

A: We implement comprehensive testing including S-parameter measurements, impedance verification, EMC pre-compliance testing, and functional validation under realistic traffic conditions. Our designs comply with IEEE 802.11 standards and FCC regulations for wireless devices.

Q: Can you support both prototype and production router PCB requirements?

A: Yes, we provide complete router PCB services from prototype development through high-volume production. Our capabilities include design optimization, component sourcing, precision assembly, comprehensive testing, and ongoing production support with full quality documentation.

Q: What assembly capabilities do you provide for router PCBs?

A: Our advanced assembly capabilities include fine-pitch BGA placement, precision SMT assembly, through-hole components, functional testing, and quality verification. We support both consumer and industrial router applications with appropriate quality standards and environmental testing.