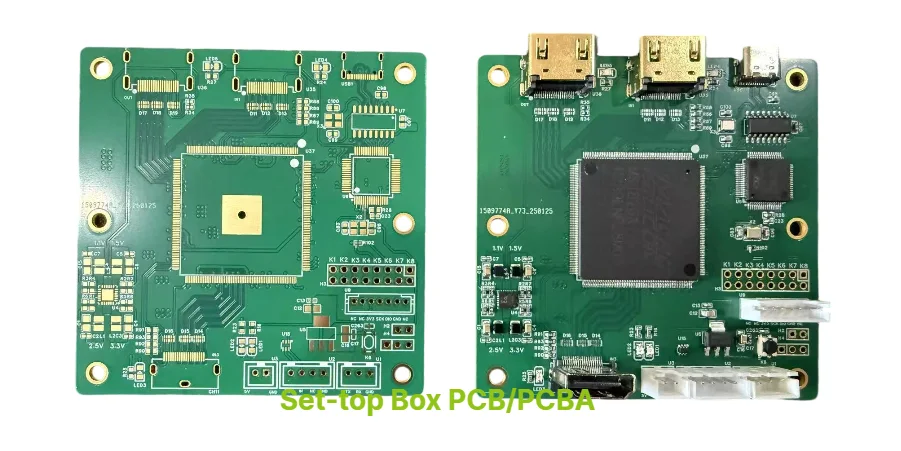

Set-top box PCBs serve as the nerve center of streaming and broadcast devices—coordinating video decoding, wireless transmission, power management, and interface delivery in an ultra-compact enclosure. As end-users demand faster performance, sharper resolution, and seamless connectivity, manufacturers must integrate increasingly complex functionality into increasingly smaller boards.

At HILPCB, we deliver engineered PCB solutions tailored to the unique challenges of IPTV receivers, OTT streamers, Android TV boxes, and hybrid satellite systems. With a focus on thermal performance, signal integrity, and manufacturing scale, we enable customers to transition quickly from prototype to production, maintaining both reliability and cost-effectiveness.

Core Architecture and Platform Requirements

A typical set-top box PCB integrates multiple functional blocks, including:

- High-efficiency power management with voltage rails from 0.9V to 5V

- ARM-based SoCs with 4K/8K decoding, AV1/H.265 support, and GPU acceleration

- DDR3/DDR4 memory interfaces with matched-length routing

- HDMI 2.1, USB 3.0, and Ethernet PHY interfaces

- Dual-band Wi-Fi 5/6, Bluetooth 5.0, and optional ZigBee

These systems demand multilayer PCB stackups—often 6 to 8 layers—configured to isolate analog, digital, and RF domains. Differential pairs for HDMI and USB are routed with ±10% impedance tolerance, and grounding strategy is optimized for both EMC compliance and power delivery stability.

The entire layout must adhere to thermal zoning: placing hot components like SoCs and PMICs near heat paths while maintaining signal length budgets for high-speed buses. Materials like high thermal PCB substrates with low Z-axis expansion coefficients prevent warping and aid in heat dissipation under continuous load.

Manufacturing Expertise for Consumer Media Devices

Our manufacturing lines are built for scale and flexibility. We handle both low-volume prototyping and high-volume production of set-top box PCBs with consistency across batches.

Capabilities include:

- Core substrates: FR4 PCB with high Tg and low-loss options for RF zones

- Layer registration tolerance: < ±75μm for high-speed multilayer boards

- Surface finish: ENIG or ENEPIG for BGA packages and PoP memory

- SMT line support for fine-pitch (0.3 mm) and high-mix component loads

Our SMT assembly solutions accommodate mixed technology, including reflow and selective wave soldering. For full system builds, turnkey assembly services integrate procurement, firmware loading, and system testing.

PCBs are tested with AOI, ICT, functional test rigs, and thermal cycling to simulate typical usage environments in consumer living rooms and commercial installations.

Signal, Power, and Thermal Co-design

Set-top boxes rely heavily on stable power delivery and EMI resilience. We implement:

- Star-grounding schemes to isolate digital and RF grounds

- Distributed decoupling for high-speed memory domains

- Multiple copper weights for high-current SoC cores

- Controlled routing paths for HDMI, USB, and PCIe (if applicable)

For thermal management, we design with:

- Thermal via arrays under high-power ICs

- Copper pours for passive heat spreading

- Optional metal shields to couple heat to enclosure frames

Our layout team runs simulation-driven DFM workflows and validates thermal hotspots with IR imaging and modeling tools.

Supported Applications and Use Cases

Our PCBs are featured in a range of media devices, including:

- Entry-level IPTV receivers with simplified Ethernet-only input

- Wi-Fi enabled OTT streaming dongles and compact TV boxes

- Android TV systems with voice control and AI upscaling

- Dual-stack hybrid cable/satellite boxes with conditional access modules

Each application demands different BOM targets, routing priorities, and mechanical tolerances. We assist customers in building platforms that adapt to global broadcast standards and meet region-specific compliance.

High-speed PCB technologies are critical for 4K HDR systems with tight timing margins and low-jitter transmission. Box-build assembly is available for customers requiring full enclosure integration, including RF shield installation, firmware programming, and burn-in testing.

Why Partner with HILPCB

Choosing the right PCB partner can define the success of your Set-top box project. At HILPCB, we combine engineering rigor with manufacturing agility to deliver PCBs that meet the performance, compliance, and cost goals of global streaming and broadcast device makers. Whether you're building entry-level IPTV receivers or premium Android TV boxes with voice and AI integration, our tailored services support rapid innovation with dependable execution.

We are certified to ISO 9001:2015 and IPC-A-610 Class 2/3, with a proven track record serving top-tier OEMs in the consumer electronics industry. Our in-house team provides PCB layout, thermal simulation, and signal integrity modeling to ensure first-pass success. With strong upstream component sourcing and turnkey assembly capabilities, HILPCB is your single-point manufacturing partner—from engineering sample to high-volume delivery.

Frequently Asked Questions About Set-top box PCB

Q: What are the key differences between Set-top box PCB and traditional television circuit boards? A: Set-top box PCBs are specifically designed for compact media streaming and broadcast reception devices, featuring specialized video decoding processors, wireless connectivity modules, and optimized power management systems. Unlike television main boards, they prioritize small form factor design, cost optimization, and streaming protocol support while maintaining high video processing performance in space-constrained enclosures.

Q: How do you manage thermal challenges in compact Set-top box designs? A: Thermal management combines strategic component placement, thermal via implementation, and optimized airflow design within plastic enclosures. High-power components like video processors and wireless chipsets are positioned to maximize heat spreading while thermal vias conduct heat to mounting points and enclosure surfaces. Advanced designs may incorporate thermal pads or heat spreaders for critical components operating under continuous load conditions.

Q: What testing procedures ensure Set-top box PCB reliability for continuous operation? A: Comprehensive testing includes electrical validation of all streaming interfaces, thermal cycling across operating temperature ranges, humidity exposure testing, and vibration resistance verification. Automated optical inspection validates assembly quality while in-circuit testing confirms component functionality. System-level testing validates complete streaming performance including video decoding, wireless connectivity, and protocol compatibility across multiple streaming platforms.

Q: Can you support both budget and premium Set-top box requirements? A: Yes, our capabilities span from basic IPTV receivers with essential streaming features to premium Android TV platforms supporting 8K decoding, advanced HDR processing, and sophisticated smart home integration. Manufacturing processes accommodate cost-optimized designs for mainstream markets and high-performance solutions for premium streaming devices while maintaining appropriate quality standards and regulatory compliance for each market segment.