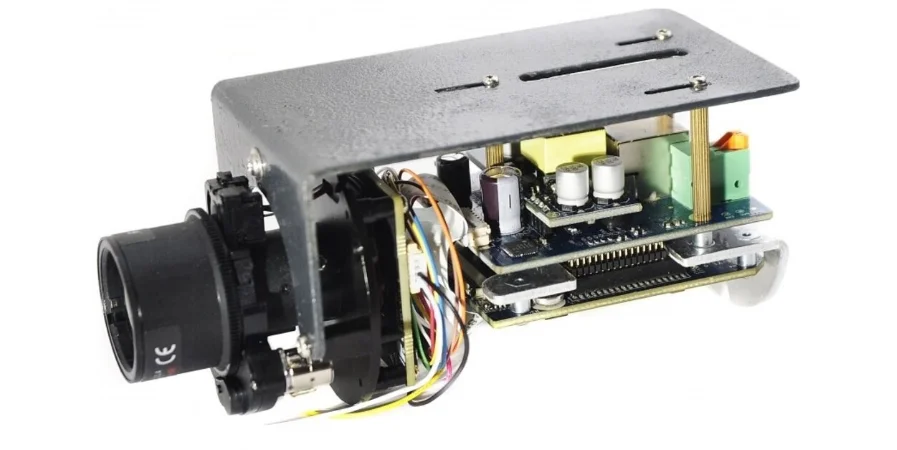

Highleap is a full-service PCB manufacturer with strong capabilities in high-frequency, HDI, and multilayer circuit board production. Our manufacturing and assembly solutions support a wide range of advanced applications—including thermal imaging PCBs, infrared camera boards, and heat detection systems used in military, security, industrial, and automotive environments.

In addition to fabrication, we provide end-to-end PCB assembly services, including SMT for thermal sensors, BGA placement, fine-pitch component mounting, and X-ray/AOI inspection—ensuring precise sensor alignment and long-term performance in sensitive thermal detection systems.

While we serve many industries beyond thermal imaging, our processes are well-suited for thermal camera PCB assembly, heat detection electronics, and other thermal-related designs that demand low-noise signal handling, environmental reliability, and compact layouts. From prototyping to production, Highleap ensures high-quality PCB delivery with consistent performance and tight process control.

High-Precision Thermal Imaging PCB Capabilities

Designing and producing thermal imaging circuit boards requires deep expertise in noise control, analog-digital separation, and thermal management. Our solutions support:

- Thermal Camera & Heat Detection PCB Design Optimized for thermal sensors, we build PCBs with low-noise analog stages, carefully managed grounding schemes, and EMI shielding to preserve thermal image clarity and signal fidelity.

- Multilayer & HDI Structures Our multilayer PCB stackups use impedance-controlled traces, blind vias, and thermally stable dielectric materials ideal for miniaturized thermal sensor arrays and compact enclosures.

- Military Thermal Imaging PCB Applications From targeting systems to vehicle-mounted thermal cameras, we build ruggedized PCBs that meet MIL-STD-461, MIL-STD-883, and withstand extreme vibration, temperature, and shock.

- Advanced Thermal Management Systems Our high thermal PCB solutions feature integrated thermoelectric cooling, heat-spreading layers, and temperature feedback circuits to maintain thermal camera module stability and improve real-time imaging quality.

We also support hybrid thermal sensor designs, including FLIR camera PCB layouts where multiple thermal detection channels are combined in a single imaging board for enhanced heat detection capabilities.

Advanced PCB Manufacturing and Testing for Thermal Imaging

Our manufacturing workflow is optimized for thermal imaging PCB assemblies, where thermal signal preservation and heat management are critical:

- Controlled Material Selection We use high-Tg PCB materials with low-Dk/dissipation factor properties to reduce dielectric loss in high-frequency thermal image transfer paths, essential for long-range and real-time thermal detection systems.

- Precision SMT and Thermal Sensor Placement Our SMT assembly processes handle delicate thermal imaging sensors using ultra-fine pitch placement with accuracy under 15 microns, ensuring correct alignment and optimal thermal detection performance.

- AOI, X-ray, and Functional Testing All thermal imaging camera PCBs undergo visual and internal defect inspection. Functional tests measure thermal sensitivity, temperature gradient behavior, and signal-to-noise ratios.

- Environmental Stress Screening We simulate extreme conditions through temperature cycling (-55°C to +85°C), vibration, and humidity tests, validating performance in field-deployed military thermal systems and outdoor heat detection cameras.

- EMC Compliance for Defense & Security Our thermal imaging and heat detection PCBs comply with MIL-STD-461 and commercial EMC standards, suitable for both defense applications and CE/FCC-certified surveillance gear.

Thermal Imaging and Heat Detection PCB Applications

We manufacture high-performance PCBs for thermal imaging, heat detection, and temperature monitoring applications across a broad range of industries:

- Military and Defense Systems Thermal imaging scopes, heat-seeking targeting systems, helmet-mounted thermal displays, vehicle-mounted infrared cameras, UAV-based thermal reconnaissance platforms.

- Security and Surveillance Fixed-position thermal surveillance cameras, motion-activated heat sensors, perimeter thermal monitoring systems, thermal IP cameras for remote facilities.

- Automotive and Transportation Thermal ADAS modules, driver-assist heat detection systems, pedestrian thermal detection units, off-road vehicle thermal camera systems, intelligent thermal sensing.

- Industrial Automation and Inspection Non-contact thermal inspection systems, robotic thermal vision modules, smart factory heat monitoring, predictive maintenance thermal sensors, flame and leak detection systems.

- Medical and Healthcare Devices Thermal diagnostic imaging, fever screening devices, non-invasive temperature monitoring tools, patient thermal sensing units, thermal therapy control systems.

- Consumer Electronics and Smart Devices Smart home thermal cameras, heat-enabled doorbells, handheld thermal monoculars, outdoor gear with integrated thermal sensors, wearable temperature trackers.

- Aerospace and UAV Platforms Thermal imaging PCB systems for drones, thermal payload integration for aerial mapping, high-altitude thermal surveillance sensors, autonomous UAV thermal vision modules.

- Research and Scientific Instruments Laboratory thermal cameras, thermal spectrometry equipment, calibrated heat detection arrays, controlled-environment thermal imaging systems.

- Energy and Utility Monitoring Substation thermal monitoring, powerline heat diagnostics, pipeline thermal integrity inspection, thermal leakage detection in energy infrastructure.

- Firefighting and Emergency Services Firefighter helmet-mounted thermal vision, search-and-rescue drones with heat sensors, rugged handheld thermal cameras for smoke penetration.

We support custom PCB development for all thermal imaging and heat detection use cases—balancing performance, integration, and reliability requirements across mission-critical, commercial, and emerging applications.

Global Certifications and Compliance for Thermal Imaging PCBs

HILPCB ensures that every thermal imaging, heat detection, or temperature monitoring PCB we manufacture meets strict international compliance standards. Whether deployed in military-grade thermal optics or commercial heat detection cameras, our boards are built under fully certified processes to ensure long-term reliability, regulatory approval, and procurement readiness.

We support a wide range of certification frameworks, including MIL-STD-461, MIL-STD-883, IPC Class 3 workmanship, and AS9100-compliant workflows—making our solutions ideal for mission-critical thermal imaging circuit boards, aerospace-grade electronics, and ruggedized defense systems. For global commercial deployment, we offer full CE, FCC, and RoHS compliance for thermal security camera PCBs, automotive heat detection systems, and industrial thermal modules.

In addition, we support ITAR-controlled and export-restricted programs, with secure documentation handling, vetted material sourcing, and structured traceability. Customers receive detailed quality documentation including Certificates of Conformance (CoC), First Article Inspection (FAI) reports, and test data logs—ensuring every thermal imaging PCB assembly meets both performance and regulatory expectations worldwide.

Why Choose Highleap as Your Thermal Imaging PCB Partner

We go beyond standard PCB production—offering complete support for your thermal imaging and heat detection electronics development:

- Specialized in High-Frequency and Thermal Circuit Design Precision routing, signal isolation, and thermal-aware stackups designed for thermal imaging PCB signal integrity and long-term thermal stability.

- Military-Grade Manufacturing Standards MIL-STD-883, IPC Class 3, and AS9100-based systems ensure full traceability and government-grade quality.

- Rapid Prototyping and Scalable Volume Production From initial development to long-term production, we support flexible batch sizes and on-time delivery for fast-moving projects.

- Expert Engineering Support Thermal simulation, sensor interface consulting, and EMC analysis for thermal camera module PCB performance optimization.

- Full Lifecycle Services Our turnkey assembly approach includes sourcing, assembly, testing, design updates, and obsolescence management for long-term thermal imaging system success.

For applications requiring exceptional thermal performance, our ceramic PCB solutions provide superior thermal conductivity and dimensional stability essential for high-power thermal detection systems.

Thermal Imaging PCB FAQ

What is a thermal imaging PCB? A thermal imaging PCB is a specialized circuit board designed to process thermal and infrared signals from heat detection sensors. It integrates low-noise amplifiers, ADCs, and thermal control components to deliver real-time heat imaging in various environmental conditions.

Can Highleap support military thermal imaging electronics? Yes. We meet MIL-STD-461, MIL-STD-883, IPC Class 3, and can support ITAR-compliant builds for defense contractors worldwide.

What's different about thermal imaging PCBs compared to standard camera PCBs? Thermal camera PCBs must manage heat efficiently while maintaining sensor precision. We use high-Tg materials, embedded copper planes, and thermal vias to ensure accurate operation across temperature extremes and thermal gradients.

Do you manufacture camera module PCBs with integrated thermal sensors? Yes. We build compact thermal PCB assemblies with precision-aligned CMOS or thermal sensor integration, suitable for drones, surveillance, and industrial thermal vision systems.

Can I order both prototype and production runs for thermal imaging PCBs? Absolutely. We support full lifecycle manufacturing—from initial design to high-volume thermal imaging PCB production, with consistent quality and delivery timelines.