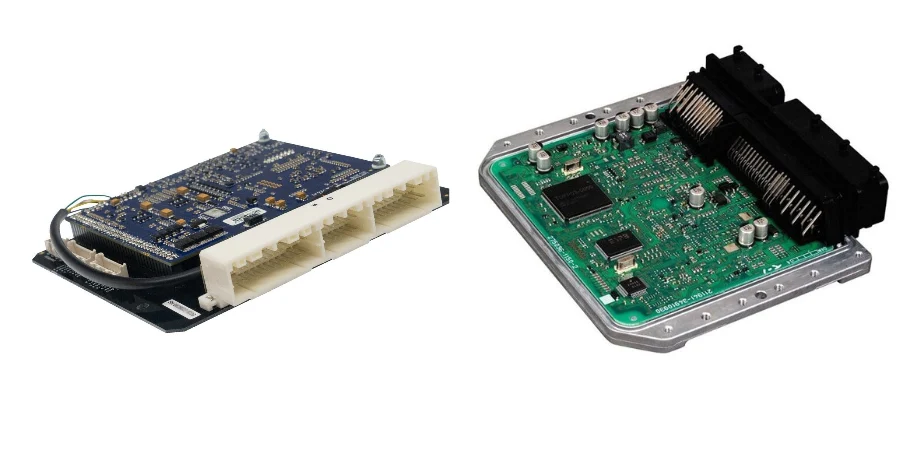

Highleap PCB Factory (HILPCB) delivers cutting-edge automotive ECU PCB manufacturing solutions meeting stringent automotive standards for harsh operating environments. Our advanced processes combine precision fabrication, EMI mitigation, and comprehensive quality systems producing reliable engine control unit PCBs for critical automotive applications.

Modern automotive ECU PCBs require sophisticated design approaches addressing electromagnetic compatibility (EMC), thermal management, and long-term reliability. Our automotive-grade manufacturing ensures compliance with ISO/TS 16949, AEC-Q100, and automotive EMC standards including CISPR 25 and ISO 11452.

Automotive ECU PCB EMI Control and Design Excellence

Automotive ECU PCB design demands sophisticated electromagnetic interference (EMI) mitigation for reliable operation in electrically noisy environments. HILPCB implements advanced layout optimization, grounding methodologies, and shielding solutions minimizing EMI while maximizing signal integrity.

Core EMI Mitigation Strategies:

• Optimized PCB Layout: Strategic component placement separates analog/digital sections, minimizes current loops, utilizes controlled impedance routing over continuous ground planes

• Multi-Layer Grounding: Dedicated ground planes in multilayer PCB provide low-impedance return paths with inner shielding layers isolating sensitive circuits

• Advanced Filtering: Integrated PI filters, ferrite beads, and strategic decoupling networks suppress power supply noise and switching transients

• Shielded Implementation: Component-level shielding and EMI containment structures prevent interference coupling while maintaining thermal dissipation

Our ECU designs adhere to CISPR 25 Class 5 emission limits and ISO 11452 immunity standards with pre-compliance testing ensuring first-pass EMC certification. Specialized high-frequency PCB techniques enable reliable ADAS and engine management operation from -40°C to +85°C.

High-Reliability Manufacturing and Materials

Automotive ECU PCB manufacturing utilizes advanced fabrication processes and automotive-qualified materials ensuring long-term reliability under extreme conditions. ISO/TS 16949 certified systems deliver consistent quality meeting stringent automotive requirements.

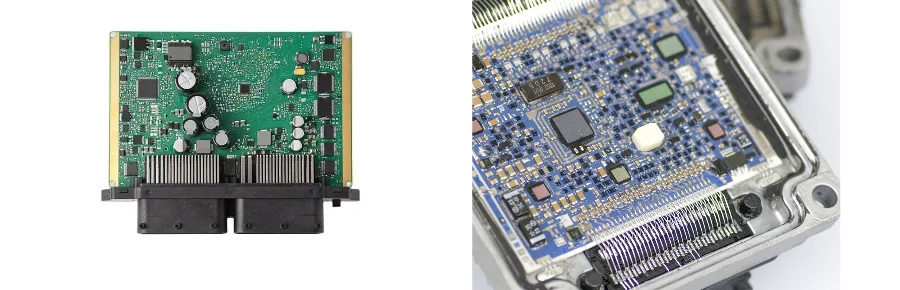

Advanced Material Systems: Automotive-grade substrates including high-Tg FR4, polyimide, and high thermal PCB laminates provide enhanced thermal stability and mechanical durability. Heavy copper PCB configurations support high-current applications with copper thicknesses from 2 oz to 10 oz.

Precision Processes: Advanced drilling and plating ensure reliable via formation under thermal cycling. Controlled impedance manufacturing maintains signal integrity for CAN bus, LIN bus, and Ethernet protocols. Surface finishes including HASL, ENIG, and OSP meet automotive durability standards.

Thermal Management and Reliability Engineering

Automotive ECU PCBs require sophisticated thermal management for harsh environments. HILPCB implements advanced thermal design techniques optimizing heat dissipation while maintaining electrical performance.

Strategic copper pour optimization, thermal vias, and heat spreading distribute thermal loads across PCB structures. Metal core PCB configurations provide enhanced conductivity for high-power LED and power electronics applications.

Comprehensive reliability testing includes thermal cycling, humidity bias, and mechanical stress evaluation per automotive standards. Accelerated life testing validates 10+ year operational requirements while automated optical inspection and X-ray analysis verify assembly integrity.

Specialized ECU Applications and Advanced PCB Technologies

Modern automotive ECUs are no longer limited to engine or transmission control. They now power a wide range of safety-critical and performance-intensive systems, including:

- Advanced Driver Assistance Systems (ADAS)

- Battery Management Systems (BMS) in EVs

- Autonomous navigation and sensor fusion modules

- In-vehicle infotainment and connectivity gateways

- Brake-by-wire and steer-by-wire controls

These evolving demands require PCBs that deliver high-density integration, reliable signal integrity, and robust thermal/vibration tolerance—often within tight form factors.

To meet these challenges, manufacturers increasingly adopt:

HDI PCBs:High-Density Interconnect PCBs support multi-layer signal routing through laser-drilled microvias, blind/buried vias, and sequential lamination. This enables compact ECU designs with reduced EMI, shorter signal paths, and improved electrical performance—critical for high-speed interfaces like CAN FD, Ethernet, and LVDS.

Rigid-Flex PCBs:ECU modules installed within tight enclosures or exposed to mechanical stress benefit from rigid-flex solutions. These boards combine rigid control layers with flexible interconnects, allowing 3D packaging, reducing connector failures, and withstanding automotive-grade thermal cycling and vibration—ideal for embedded camera modules, head-up displays, or integrated sensor clusters.

Professional Automotive Services at HILPCB

Highleap PCB Factory delivers comprehensive automotive ECU PCB services with state-of-the-art equipment and automotive-qualified processes. ISO/TS 16949 certification ensures consistent quality while PPAP documentation provides complete traceability.

HILPCB integrates ECU fabrication with turnkey assembly including SMT assembly capabilities. Advanced testing includes in-circuit testing, functional verification, and environmental stress screening validating performance under automotive conditions.

Frequently Asked Questions About Automotive ECU PCB

Q: What makes automotive ECU PCB different from standard PCB designs? A: Automotive ECU PCBs require enhanced EMI shielding, automotive-grade materials rated for -40°C to +85°C operation, compliance with AEC-Q100 and ISO/TS 16949 standards, and specialized thermal management for harsh automotive environments with 10+ year reliability requirements.

Q: How does HILPCB ensure automotive ECU PCB quality and reliability? A: We maintain ISO/TS 16949 certification, implement PPAP documentation processes, conduct comprehensive reliability testing including thermal cycling and vibration testing, utilize automotive-qualified materials, and provide statistical process control throughout manufacturing.

Q: What automotive applications can your ECU PCBs support? A: Our automotive ECU PCBs serve engine control units, transmission control modules, body control units, ADAS systems, electric vehicle powertrains, hybrid propulsion systems, infotainment systems, and autonomous driving control units across passenger and commercial vehicles.

Q: What is the typical lead time for automotive ECU PCB manufacturing? A: Standard automotive ECU PCB lead times range from 10-15 days for prototype quantities and 15-20 days for production volumes, depending on complexity, layer count, and special requirements. Expedited services available for urgent automotive programs with 5-7 day turnaround options.

Q: Can you provide automotive ECU PCB assembly services beyond fabrication? A: Yes, HILPCB offers complete turnkey assembly services including SMT assembly, through-hole assembly, functional testing, conformal coating application, automotive-grade component sourcing, and full PPAP documentation for seamless integration into automotive production programs.