Finding the right circuit board manufacturing partner can make or break your electronics project. Whether you're developing consumer electronics, industrial equipment, or cutting-edge IoT devices, understanding PCB manufacturing processes helps you make informed decisions about quality, cost, and delivery timelines.

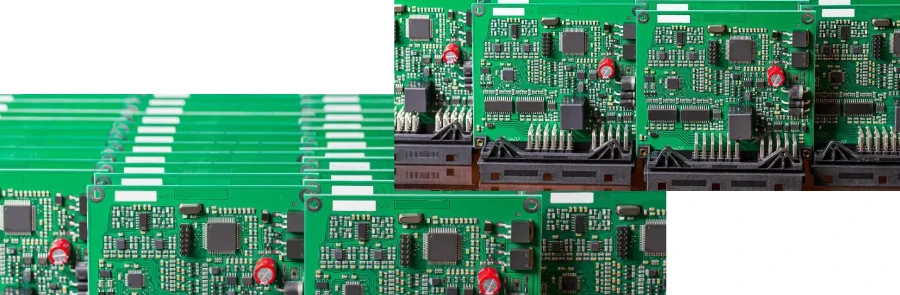

At Highleap PCB Factory, we've manufactured over 100,000 PCBs for clients ranging from startups to Fortune 500 companies. This comprehensive guide reveals what goes into professional circuit board manufacturing and how to choose the right manufacturing partner for your needs.

Why PCB Manufacturing Quality Matters

Poor PCB manufacturing can destroy months of design work and product development investment. We've seen customers come to us after experiencing these costly problems with other manufacturers:

- Circuit failures in the field leading to expensive recalls

- Inconsistent quality causing assembly line delays

- Delivery delays missing critical product launch deadlines

- Hidden costs from rework and quality issues

Professional circuit board manufacturing eliminates these risks through proven processes, advanced equipment, and rigorous quality control.

What Makes Professional Circuit Board Manufacturing Different

Advanced Manufacturing Capabilities

Modern PCB manufacturing requires sophisticated equipment and expertise to meet today's demanding requirements:

Precision Manufacturing:

- Line widths down to 3 mil (75μm) for high-density designs

- Via drilling accuracy within ±2 mil (50μm)

- Layer-to-layer registration accuracy ±1 mil (25μm)

- Impedance control tolerance ±5%

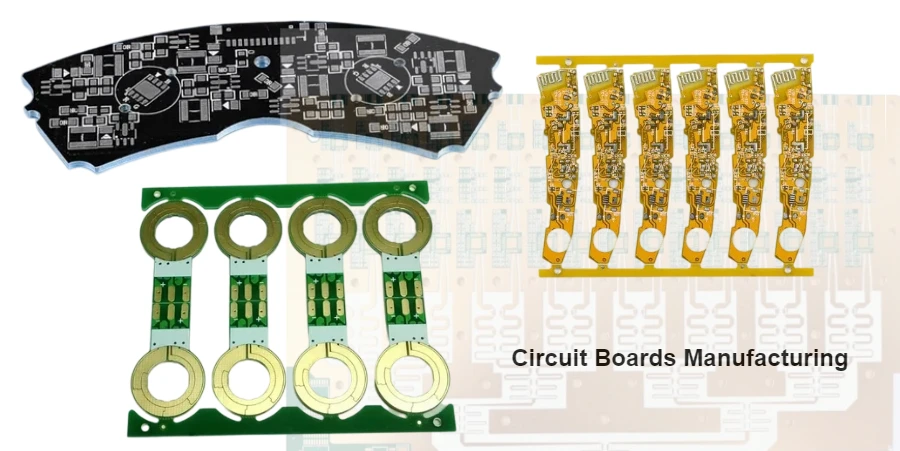

Comprehensive Material Options:

- FR4 PCBs: Cost-effective standard for most applications

- High-frequency PCBs: For RF and 5G applications requiring low signal loss

- Metal Core PCBs: Superior thermal management for LED and power electronics

- Flex PCBs: For wearables and space-constrained applications

- Rogers PCBs: Premium materials for demanding RF applications

Quality Certifications That Matter

When evaluating PCB manufacturers, look for these essential certifications:

- ISO 9001:2015 - Quality management systems

- IATF 16949 - Automotive industry standards

- ISO 14001 - Environmental management

- UL Recognition - Safety compliance for North American markets

- RoHS Compliance - Environmental and safety regulations

🏆 Highleap PCB Manufacturing Advantages

✅ Guaranteed Quality

ISO 9001:2015 certified with 99.7% first-pass yield rate and comprehensive quality testing.

⚡ Fast Turnaround

Quick-turn prototypes in 24-48 hours, production runs in 5-7 days with on-time delivery guarantee.

💰 Competitive Pricing

Factory-direct pricing with transparent quotes and no hidden fees. Volume discounts available.

🔧 Expert Support

DFM analysis, engineering support, and dedicated project management throughout production.

The Complete PCB Manufacturing Process

Understanding the manufacturing process helps you optimize your designs and set realistic expectations for quality and delivery times.

Step 1: Design Review and DFM Analysis

Before production begins, professional manufacturers perform Design for Manufacturing (DFM) analysis to identify potential issues:

- Trace width and spacing verification against manufacturing capabilities

- Via size and placement optimization for drilling accuracy

- Component placement review for assembly considerations

- Stackup optimization for electrical performance and cost

This analysis prevents costly delays and ensures your PCB can be manufactured reliably at scale.

Step 2: Material Selection and Procurement

The choice of substrate material dramatically impacts PCB performance, reliability, and cost:

Standard Applications: FR4 PCBs offer the best balance of performance and cost for most electronic devices.

High-Speed/RF Applications: High-frequency PCBs with specialized dielectrics minimize signal loss and maintain impedance control.

Thermal Management: Metal Core PCBs efficiently dissipate heat in LED drivers and power electronics.

Flexible Circuits: Flex PCBs enable innovative form factors for wearables and space-constrained applications.

For precise impedance calculations during design, use our impedance calculator tool to ensure optimal signal integrity.

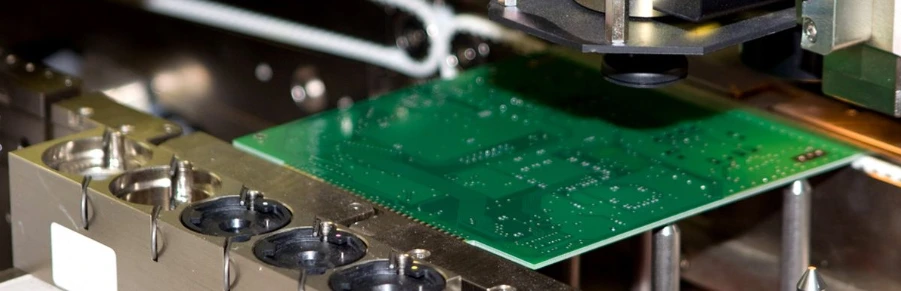

Step 3: Precision Manufacturing Process

Modern PCB manufacturing follows a carefully controlled sequence:

Layer Construction:

- Copper foil lamination to substrate materials

- Photoresist application and UV exposure

- Chemical etching to form circuit patterns

- Layer lamination for multilayer circuit boards

Drilling Operations:

- Computer-controlled drilling for vias and component holes

- Precision laser drilling for HDI PCBs requiring microvias

- Hole cleaning and surface preparation

Plating and Finishing:

- Electroless copper deposition for via connections

- Pattern plating to achieve required copper thickness

- Surface finishing (HASL, ENIG, OSP) for optimal solderability

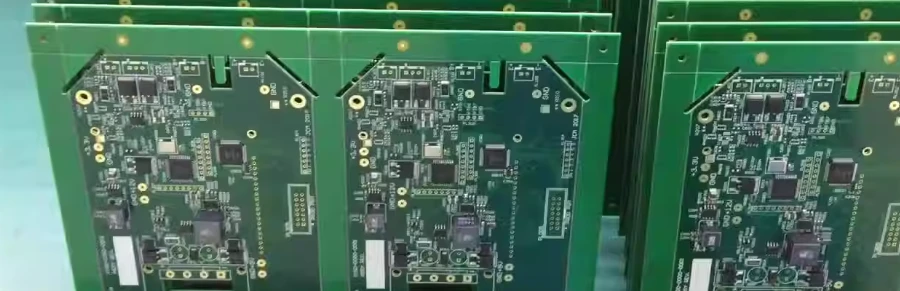

Step 4: Quality Control and Testing

Professional PCB manufacturers implement comprehensive quality control:

Automated Inspection:

- Optical inspection for dimensional accuracy

- Electrical testing for continuity and isolation

- Impedance measurement for controlled impedance circuits

- Visual inspection for cosmetic defects

Testing Standards:

- IPC-A-600 acceptance criteria for PCB quality

- J-STD-001 requirements for soldering standards

- Customer-specific testing requirements

- Statistical process control monitoring

Our comprehensive circuit board testing services ensure every PCB meets specified performance requirements.

How to Choose the Right PCB Manufacturing Partner

A true PCB partner should deliver more than just fabrication. Today’s projects demand a manufacturer who can produce a wide range of PCB types and also provide complete assembly, testing, and lifecycle support. Choosing wisely ensures not only reliable boards but also smoother production and faster time-to-market.

Key Capabilities to Look For

- Full PCB Range: From single-layer, double-layer to advanced multilayer PCBs, HDI, flexible, rigid-flex, metal-core, and high-frequency PCBs

- Assembly Expertise: Complete PCB assembly services including SMT, through-hole, mixed technology, and turnkey solutions

- Manufacturing Precision: Fine-line capability, microvia drilling, multiple surface finishes (ENIG, HASL, OSP), and advanced material handling

- Quality Systems: ISO/IPC-certified processes, AOI, X-ray, impedance and functional testing, full traceability, and strict SPC monitoring

- Engineering Support: DFM analysis, prototyping, design consultation, and technical collaboration to optimize yield and reduce cost

Why Highleap PCB Factory

At Highleap PCB Factory, we provide one-stop PCB manufacturing and assembly solutions. With over 15 years of industry experience, we can produce everything from prototypes to high-volume production across diverse PCB technologies. Our in-house assembly lines ensure your boards are tested, assembled, and delivered ready for integration. Combined with global shipping and responsive engineering support, we help our clients cut lead times, lower risks, and bring products to market faster.

Cost Optimization Strategies

Factors Affecting PCB Manufacturing Cost

Design Complexity:

- Layer count and stackup complexity

- Via types (through-hole vs. microvia)

- Minimum trace width and spacing requirements

- Special features (blind vias, embedded components)

Material Selection:

- Standard FR4 vs. specialty materials

- Copper weight requirements

- Surface finish selection

- Thickness specifications

Volume and Timing:

- Prototype vs. production quantities

- Standard vs. expedited delivery

- Panel utilization efficiency

- Setup and tooling costs

Cost-Effective Manufacturing Tips

- Optimize Panel Utilization: Design PCB dimensions to fit efficiently on standard panel sizes

- Standardize Materials: Use common thicknesses and copper weights when possible

- Minimize Layer Count: Achieve routing goals with fewer layers through careful design

- Choose Appropriate Surface Finish: Balance performance requirements with cost considerations

- Plan for Volume: Consider long-term volume requirements in initial design decisions

Working with Your Manufacturing Partner

Successful Project Management

Clear Communication:

- Provide complete specifications and requirements

- Establish clear timelines and milestones

- Maintain regular project status updates

- Document all changes and approvals

Design Collaboration:

- Leverage manufacturer's DFM expertise

- Consider manufacturing constraints early in design

- Review and approve prototypes before production

- Plan for testing and validation requirements

From Design to Production

The transition from custom circuit board design to manufacturing requires careful planning:

- Design Finalization: Complete electrical and mechanical design validation

- Prototype Phase: Build and test prototypes to validate design

- Production Preparation: Finalize specifications and manufacturing documentation

- Manufacturing: Execute production with quality monitoring

- Assembly Planning: Coordinate with circuit board assembly services

Best Practices for Selecting a Circuit Board Manufacturing Company

When evaluating circuit board manufacturing options, consider the total value proposition beyond just price. The right manufacturing partner becomes an extension of your engineering team, contributing to product success through:

- Quality Excellence: Consistent, reliable products that enhance your reputation

- Technical Expertise: Engineering support that improves your designs

- Supply Chain Reliability: On-time delivery that supports your business goals

- Cost Optimization: Efficient processes that improve your profit margins

For guidance on selecting the right manufacturing approach, see our comprehensive guide on buying circuit boards.

Ready to Start Your PCB Manufacturing Project?

Highleap PCB Factory combines advanced manufacturing capabilities with exceptional service to deliver the PCBs your products deserve. Our ISO 9001:2015 certified facility has produced over 100,000 high-quality PCBs for customers worldwide.

What sets us apart:

- ✅ Guaranteed Quality: 99.7% first-pass yield rate with comprehensive testing

- ⚡ Fast Turnaround: Prototypes in 24-48 hours, production in 5-7 days

- 💰 Competitive Pricing: Factory-direct pricing with transparent quotes

- 🔧 Expert Support: DFM analysis and dedicated project management

- 🏆 Proven Experience: Over 15 years serving customers from startups to Fortune 500

Don't let PCB manufacturing delays or quality issues derail your product launch. Partner with proven experts who understand your success depends on reliable, high-quality circuit boards delivered on time.

Contact our engineering team today to discuss your project requirements and discover how our advanced manufacturing capabilities can bring your innovative designs to life.