HILPCB delivers cutting-edge GPS PCB manufacturing solutions combining precision RF design with advanced fabrication processes. Our specialized GPS and GNSS circuit board solutions enable reliable satellite navigation across automotive, IoT, and consumer electronics applications requiring exceptional positioning accuracy.

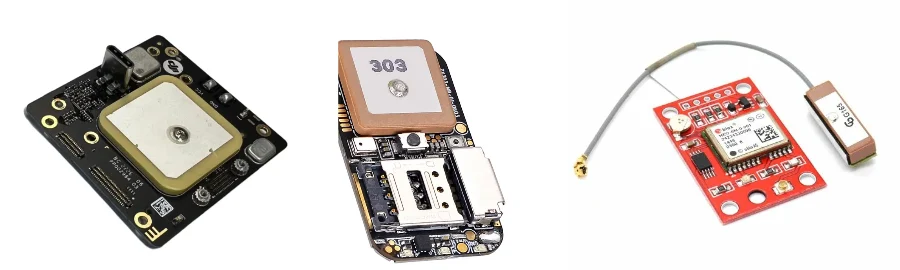

Modern GPS PCB designs integrate sophisticated RF front-ends, antenna matching networks, and signal processing capabilities within compact form factors. Our expertise spans from simple GPS receiver modules to complex multi-constellation GNSS systems supporting GPS, GLONASS, Galileo, and BeiDou simultaneously.

GPS PCB Design Fundamentals and RF Architecture

GPS PCB design requires sophisticated understanding of satellite signal characteristics, RF front-end architecture, and antenna integration techniques. The fundamental challenge lies in processing extremely weak satellite signals (-130 dBm typical) while maintaining signal integrity in electrically noisy environments.

Core GPS PCB Architecture Components:

• RF Front-End Design: Low-noise amplification, filtering, and down-conversion stages optimized for L1 (1575.42 MHz), L2 (1227.60 MHz), and L5 (1176.45 MHz) GPS frequencies

• Antenna Integration: Patch antenna, ceramic chip antenna, or external antenna interfacing with precise impedance matching and minimal insertion loss

• Clock and Timing Circuits: High-stability crystal oscillators and phase-locked loops (PLLs) enabling accurate time-of-flight measurements essential for positioning calculations

• Digital Signal Processing: Correlation engines, tracking loops, and navigation processors extracting positioning data from spread-spectrum satellite signals

The GPS signal structure utilizes code division multiple access (CDMA) with each satellite transmitting unique pseudo-random noise (PRN) codes. GPS PCB receivers must simultaneously track multiple satellites, performing correlation operations to extract range measurements. This requires careful analog-to-digital converter (ADC) design with sufficient dynamic range and sampling rate to preserve signal fidelity.

Advanced GNSS Integration Considerations:

Modern GPS PCB designs increasingly support multi-constellation operation, simultaneously receiving GPS, GLONASS, Galileo, and BeiDou signals. This multi-GNSS capability requires broader RF bandwidth, additional filtering complexity, and enhanced digital processing power. High-frequency PCB substrates become critical for maintaining signal integrity across extended frequency ranges while minimizing insertion loss and phase distortion.

Antenna diversity and MIMO techniques are emerging in high-performance GPS PCB applications. Multiple antenna elements with different polarizations or spatial orientations improve signal reception in challenging environments including urban canyons, indoor locations, and mobile platforms experiencing attitude variations.

Precision Timing and Synchronization:

GPS PCB designs for timing applications require exceptional clock stability and phase noise performance. Disciplined oscillators using GPS timing references achieve sub-nanosecond accuracy, essential for telecommunications infrastructure, financial trading systems, and scientific instrumentation. Temperature-compensated crystal oscillators (TCXOs) and oven-controlled crystal oscillators (OCXOs) integrated with GPS timing receivers provide holdover capability during satellite signal outages.

Signal Integrity and EMI Mitigation Strategies

GPS PCB design presents unique signal integrity challenges due to the extremely low power levels of satellite signals and susceptibility to interference. Effective EMI mitigation strategies are essential for reliable GPS performance in complex electronic systems.

Critical Signal Integrity Considerations:

• Noise Floor Management: GPS signals arrive at -130 dBm, requiring noise floors below -140 dBm for adequate signal-to-noise ratio. Every component and trace contributes to overall system noise

• Impedance Control: Precise 50Ω impedance matching throughout the RF signal path prevents reflections that degrade sensitivity. Controlled impedance manufacturing tolerances within ±5% are essential

• Isolation Techniques: RF and digital sections require careful isolation to prevent digital switching noise from corrupting weak GPS signals. Separate ground planes with single-point connections are recommended

• Shielding Implementation: Strategic EMI shielding around GPS receivers, LNAs, and critical RF traces prevents external interference while maintaining thermal dissipation

Advanced EMI Mitigation Techniques:

Power supply noise represents a significant threat to GPS PCB performance. Linear regulators with exceptional power supply rejection ratio (PSRR) are preferred over switching regulators for sensitive analog sections. When switching regulators are necessary, careful PCB layout with dedicated power planes and strategic bypassing minimizes conducted and radiated emissions.

Clock signal distribution requires special attention in GPS PCB designs. Low-jitter clock generation and distribution networks prevent phase noise that degrades correlation performance. Differential signaling for high-frequency clocks reduces EMI while improving noise immunity.

Grounding and Layout Optimization:

GPS PCB ground plane design significantly impacts performance. Continuous ground planes provide low-impedance return paths for RF signals while serving as electromagnetic shields. Strategic placement of ground vias creates virtual walls isolating sensitive circuits from interference sources.

Mixed-signal layout techniques become critical when GPS functionality is integrated with digital processing capabilities. Careful partitioning of analog and digital sections, with controlled crossing points and filtered power supplies, maintains GPS sensitivity while enabling complex digital signal processing.

Manufacturing Excellence and Substrate Selection

GPS PCB manufacturing demands exceptional precision and quality control to achieve the performance levels required for reliable satellite navigation. Substrate selection, dimensional accuracy, and process control directly impact GPS receiver sensitivity and positioning accuracy.

Advanced Substrate Technologies:

Rogers PCB materials including RO4003C and RO4350B provide optimal dielectric properties for GPS applications. Low dielectric constant (Dk) values of 3.38-3.48 and minimal loss tangent (0.0027 typical) ensure excellent RF performance with stable characteristics across temperature and humidity variations.

For cost-sensitive applications, high-quality FR4 PCB substrates with controlled dielectric properties can provide adequate performance for L1-only GPS receivers. However, dual-band and precision timing applications benefit significantly from low-loss dielectric materials.

Precision Manufacturing Processes:

• Dimensional Control: GPS antenna elements require dimensional accuracy within ±25 μm to maintain proper resonant frequency and impedance characteristics

• Copper Surface Quality: Low-profile copper treatments minimize conductor losses at GPS frequencies, improving overall system sensitivity

• Via Technology: Controlled depth drilling and reliable plating ensure consistent via impedance and signal integrity throughout the PCB stackup

• Surface Finish Selection: ENIG (Electroless Nickel Immersion Gold) provides excellent solderability and contact resistance for RF connections while maintaining long-term reliability

Quality Assurance and Testing:

Comprehensive GPS PCB testing includes S-parameter measurements, return loss analysis, and insertion loss characterization across GPS frequency bands. Automated optical inspection (AOI) and automated X-ray inspection (AXI) verify assembly quality and detect potential reliability issues.

Environmental testing validates GPS PCB performance across operational temperature ranges typically spanning -40°C to +85°C for automotive applications and -20°C to +70°C for consumer electronics. Thermal cycling, humidity testing, and mechanical stress evaluation ensure long-term reliability in demanding applications.

Advanced Assembly Techniques:

HDI PCB construction enables miniaturization of GPS modules while maintaining signal integrity. Microvias and sequential lamination support high-density component placement essential for smartphone and wearable applications.

Fine-pitch component assembly requires precision SMT assembly capabilities with placement accuracies within ±25 μm for critical RF components. Specialized handling procedures for moisture-sensitive GPS chipsets and careful reflow profile optimization prevent component damage while ensuring reliable solder joints.

Professional GPS PCB Services and Support

HILPCB provides comprehensive GPS PCB services from initial design consultation through high-volume production and testing. Our RF engineering expertise ensures optimal GPS performance while maintaining cost-effectiveness and manufacturability.

Design and Engineering Services:

• RF Simulation and Modeling: Electromagnetic field simulation tools optimize antenna performance, impedance matching, and EMI mitigation strategies

• Signal Integrity Analysis: Comprehensive pre-layout simulation identifies potential signal integrity issues and optimizes routing strategies using our impedance calculator tools

• Thermal Management: Advanced thermal modeling ensures reliable operation across temperature extremes while minimizing component stress

• Design for Manufacturing (DFM): Early manufacturability assessment prevents production issues and optimizes yield while maintaining performance specifications

Manufacturing and Assembly Capabilities:

Complete turnkey assembly services include component sourcing, assembly, testing, and quality assurance. Our automotive-qualified processes meet stringent requirements for vehicle navigation systems and safety-critical applications.

Advanced testing capabilities include GPS signal simulation, sensitivity measurements, and comprehensive functional validation. Anechoic chamber testing facilities enable accurate antenna pattern characterization and radiation efficiency measurements.

Quality Systems and Certification:

ISO 9001:2015 quality management systems ensure consistent GPS PCB quality and traceability throughout production. Automotive applications benefit from ISO/TS 16949 certification and Production Part Approval Process (PPAP) documentation.

Environmental compliance includes RoHS, REACH, and conflict minerals reporting ensuring global market access for GPS PCB products.

Frequently Asked Questions About GPS PCB

Q: What makes GPS PCB design different from standard RF PCBs? A: GPS PCB design requires exceptional sensitivity to detect -130 dBm satellite signals, precise timing capabilities for range measurements, and multi-frequency support for modern GNSS constellations. Critical considerations include ultra-low noise design, advanced EMI mitigation, and high-stability clock generation.

Q: Which substrate materials are best for GPS PCB applications? A: Rogers PCB materials like RO4003C provide optimal performance with low loss tangent and stable dielectric properties. For cost-sensitive applications, high-quality FR4 substrates can work for L1-only GPS. Dual-frequency and precision timing applications benefit from premium low-loss materials.

Q: How do you ensure GPS PCB performance in high-interference environments? A: We implement comprehensive EMI mitigation including strategic shielding, careful grounding design, power supply filtering, and isolation between analog/digital sections. Advanced layout techniques and component selection minimize noise while maintaining GPS sensitivity.

Q: What testing capabilities do you provide for GPS PCBs? A: Our testing includes S-parameter measurements, sensitivity testing with GPS simulators, antenna pattern characterization in anechoic chambers, environmental stress testing, and comprehensive functional validation. We provide complete performance verification and quality documentation.

Q: Can you support both prototype and production GPS PCB requirements? A: Yes, we provide complete GPS PCB services from prototype development through high-volume production. Our capabilities include design optimization, DFM analysis, component sourcing, precision assembly, testing, and ongoing production support with full quality traceability.