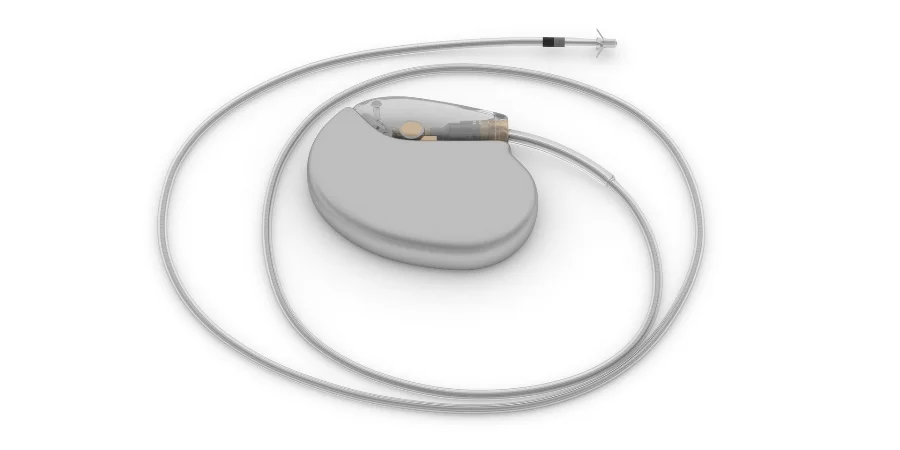

At Highleap PCB Factory (HILPCB), we specialize in the design, fabrication, and assembly of highly reliable Pacemaker PCBs for implantable cardiac devices. These specialized medical-grade PCBs require unmatched precision, rigorous material selection, and compliance with stringent international standards like ISO 13485 and IEC 60601.

As the core of a life-sustaining system, a Pacemaker PCB must support extremely low-power operation, electromagnetic immunity, biocompatibility, and long-term reliability inside the human body. HILPCB integrates advanced cleanroom assembly, traceability systems, and material validation to support demanding pacemaker and neurostimulator applications.

Pacemaker PCB Design Requirements and Specifications

The foundation of any successful pacemaker PCB begins with understanding the unique design constraints of implantable cardiac devices. Unlike conventional electronics, pacemaker PCBs must operate continuously for 10-15 years while consuming minimal power and maintaining absolute reliability in the challenging biological environment of the human body.

Critical Design Parameters:

- Ultra-Low Power Consumption: Quiescent current below 5µA with pacing pulse efficiency exceeding 90% to maximize battery life

- Miniaturization Requirements: Compact form factors typically under 40mm diameter to fit within hermetic titanium enclosures

- Signal Integrity: Precision timing circuits maintaining ±0.1% accuracy for consistent cardiac pacing

- Redundant Architecture: Dual-path critical circuits ensuring fail-safe operation even with component degradation

Our engineering team implements specialized layout techniques optimized for multilayer PCB construction, incorporating dedicated analog and digital ground planes, strategic component placement for thermal management, and routing optimization that minimizes electromagnetic interference while maintaining the compact dimensions essential for implantable devices.

Biocompatible Materials for Medical PCB Manufacturing

Material selection forms the cornerstone of pacemaker PCB reliability, as every component must demonstrate long-term stability and biocompatibility when exposed to body fluids and tissues. HILPCB employs only validated materials that have undergone comprehensive testing according to ISO 10993 biocompatibility standards.

Advanced Substrate Technologies:

- Medical-Grade Polyimide: Flexible substrates offering exceptional chemical resistance and proven biostability for flex PCB applications connecting leads and sensors

- Ceramic Substrates (Al₂O₃): Superior thermal stability with zero outgassing properties, ideal for ceramic PCB designs requiring ultimate reliability

- High-Tg FR4 Variants: Specialized high-Tg PCB materials maintaining structural integrity above 170°C for hermetic sealing processes

- ENEPIG Surface Finish: Electroless nickel electroless palladium immersion gold providing superior corrosion resistance and wire bonding reliability

Each material undergoes rigorous qualification testing including accelerated aging studies, ion migration analysis, and cytotoxicity evaluation. This comprehensive validation ensures every substrate maintains its electrical and mechanical properties throughout the expected device lifetime while remaining completely safe for long-term biological contact.

EMI Shielding and Signal Integrity for Cardiac Devices

Electromagnetic compatibility represents one of the most critical challenges in pacemaker PCB design. External RF interference from mobile phones, medical equipment, or security systems could potentially disrupt pacing functions, making robust EMI protection absolutely essential for patient safety.

Comprehensive EMI Mitigation Strategies:

- Multi-Layer Shielding Architecture: Dedicated copper ground planes and localized shielding compartments isolate sensitive analog circuits from digital switching noise

- Controlled Impedance Design: Precision trace geometry calculated using our impedance calculator ensures consistent signal transmission and minimizes reflections

- Differential Signal Routing: Critical telemetry and sensing circuits employ balanced differential pairs with guard traces for maximum noise immunity

- Embedded Filtering: Strategic placement of decoupling capacitors and ferrite filters at power entry points and lead connections

Our high-frequency PCB design techniques ensure wireless telemetry functions operate reliably while maintaining electromagnetic immunity levels exceeding 200 V/m field strength as required by IEC 60601-1-2 standards. Each design undergoes comprehensive pre-compliance testing to validate EMC performance before final production.

ISO 13485 Certified PCB Assembly and Manufacturing

Manufacturing pacemaker PCBs demands adherence to the most stringent quality standards in the electronics industry. HILPCB operates under ISO 13485:2016 certification with validated processes, complete traceability, and comprehensive documentation supporting regulatory submissions worldwide.

Advanced Manufacturing Capabilities:

- Cleanroom Assembly: ISO Class 7 environment ensuring contamination-free SMT assembly of ultra-fine pitch components down to 01005 sizes

- Precision Placement: Component placement accuracy within ±25µm supporting modern BGA and CSP packages with sub-0.3mm pitch requirements

- Hybrid Integration: Wire bonding and flip-chip capabilities for specialized cardiac ASICs and custom integrated circuits

- Process Validation: Statistical process control with Cpk values exceeding 1.67 ensuring consistent manufacturing quality

Our turnkey assembly services include authenticated component sourcing with anti-counterfeit verification, supporting the complete supply chain from prototyping through volume production. Every assembly maintains complete Device History Record (DHR) documentation with unique serialization and X-ray inspection records supporting FDA and CE regulatory requirements.

Medical Device Testing Standards and Validation Protocols

Comprehensive testing and validation ensure every pacemaker PCB meets the demanding reliability requirements of life-sustaining medical devices. Our validation protocols encompass electrical, mechanical, environmental, and biocompatibility testing aligned with international medical device standards.

STRUCTURED VALIDATION APPROACH:

Electrical Performance Verification

In-circuit testing validates all functional parameters including leakage current analysis maintaining levels below 10µA, signal integrity verification exceeding 99.9% accuracy, and comprehensive parametric testing of all analog and digital circuits. Automated test equipment provides statistical validation of manufacturing consistency across production lots.

Environmental Durability Assessment

Accelerated aging protocols simulate over 15 years of implant conditions through controlled temperature cycling, humidity exposure, and corrosive environment testing. These tests validate material stability and predict long-term performance using established acceleration factors from ASTM and IEC standards.

Mechanical Reliability Testing

Shock and vibration testing subjects completed assemblies to forces exceeding normal human activity levels. Flexible circuit sections undergo cyclic bending tests exceeding 10 million cycles, simulating decades of cardiac motion. Component attachment and wire bond integrity testing confirms mechanical reliability under all operating conditions.

EMC and Safety Compliance

Electromagnetic compatibility testing validates immunity to RF interference across frequency ranges from 80 MHz to 6 GHz with field strengths up to 200 V/m. Safety testing confirms compliance with IEC 60601-1 leakage current limits and patient protection requirements.

Pacemaker PCB Manufacturing FAQ

What makes pacemaker PCBs unique compared to other medical electronics?

Pacemaker PCBs require ultra-low power consumption (< 10µA), proven biocompatible materials, hermetic sealing compatibility, and 15+ year reliability validation. They must also demonstrate electromagnetic immunity to 200 V/m field strength and maintain complete component traceability for regulatory compliance.

What certifications do you maintain for medical device manufacturing?

HILPCB maintains ISO 13485:2016 certification for medical device quality systems, IPC Class 3/A assembly standards for highest reliability applications, and validated processes supporting FDA 510(k) and PMA submissions along with CE marking requirements.

Can you support flexible circuits for pacemaker lead connections?

Yes, our flex PCB capabilities include medical-grade polyimide and LCP substrates with demonstrated flex-life exceeding 10 million cycles. These flexible interconnects integrate seamlessly with cardiac leads while maintaining electrical and mechanical reliability.

What component sizes can you accommodate for miniaturized designs?

Our advanced assembly capabilities support components down to 01005 (0.4mm x 0.2mm) with placement accuracy within ±25µm. We routinely assemble sub-0.3mm pitch BGA packages and provide HDI routing with laser-drilled microvias for maximum circuit density.

How do you ensure long-term reliability in the human body?

Reliability assurance combines proven biocompatible materials validated through ISO 10993 protocols, accelerated aging equivalent to 15+ years, comprehensive failure mode analysis (FMEA), and hermetic sealing-compatible assembly processes preventing moisture ingress throughout device lifetime.

Do you provide complete turnkey manufacturing services?

Our comprehensive turnkey assembly services include component sourcing with authenticity verification, PCB fabrication using certified materials, cleanroom assembly, comprehensive testing, and packaging. We manage the complete supply chain for medical device manufacturers from concept to production.