In modern electronics manufacturing, an accurate PCB Assembly Quote is not just about knowing the price—it's about understanding the entire production equation: cost efficiency, delivery speed, manufacturability, and reliability.

At HILPCB, we approach every quote as a technical blueprint for your project, backed by our advanced assembly capabilities, transparent pricing, and risk mitigation strategies. Whether you need 24-hour prototypes, automotive-grade production, or millions of units annually, our quoting system ensures you start with zero guesswork and end with zero compromise.

1. Why an Accurate PCB Assembly Quote Is a Strategic Advantage

A precise PCB assembly quote directly impacts:

- Budget predictability — Eliminate hidden surcharges.

- Time-to-market — Align production timelines with launch goals.

- Yield performance — Anticipate manufacturability issues before they become costly defects.

- Supply chain stability — Plan procurement to avoid shortages and delays.

We don't just "price your job"—we engineer the path to production success from the very first quotation.

2. The HILPCB Quoting Method: No Surprises, No Shortcuts

Our quoting process is engineered for clarity and reliability:

1. Data-Driven Component Pricing

- Live pricing from authorized distributors (Digi-Key, Mouser, Arrow, Avnet).

- No hidden markups—actual distributor cost + fixed procurement service fee.

- Alternate sourcing options for hard-to-find or obsolete parts.

2. Full Process Cost Breakdown

- Clear separation of setup/NRE, assembly labor, testing, and material costs.

- Tiered volume pricing for prototypes, mid-volume, and mass production.

3. Manufacturing Feasibility Validation

- Automated Design for Assembly (DFA) checks on BOM, Gerbers, and pick-and-place files.

- Early feedback on footprint alignment, placement clearances, and thermal constraints.

3.Our Core PCB Assembly Capabilities

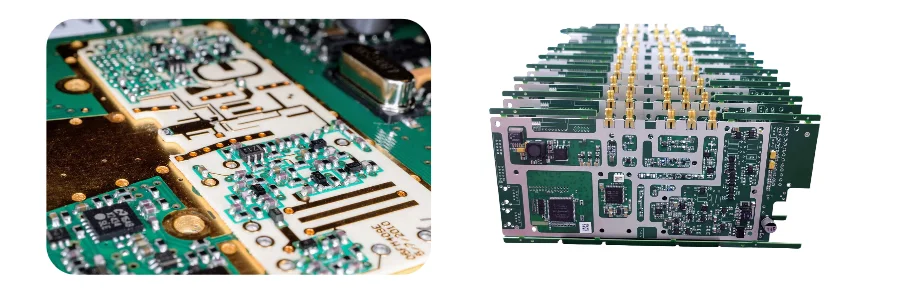

At HILPCB, our assembly capabilities go beyond standard manufacturing—we operate state-of-the-art PCBA production lines designed to handle everything from ultra-miniature consumer electronics to mission-critical aerospace systems. Our facility combines high-speed automation, fine-pitch precision, and specialized process control, enabling us to take on projects that many assemblers cannot accommodate.

Surface Mount Technology (SMT)

Our SMT lines are built for both volume efficiency and micron-level accuracy:

- Placement Accuracy: ±0.025 mm, maintained through inline vision correction and closed-loop feedback systems to ensure perfect alignment even for 01005 passives and 0.2 mm pitch BGAs with thousands of I/O pins.

- Component Capability: From ultra-miniature 01005 resistors and capacitors to large 50 mm x 50 mm modules, including fine-pitch QFNs, micro-connectors, LGA packages, CSPs, and flip-chip devices.

- High-Speed Throughput: Each SMT line achieves up to 40,000 components/hour, allowing rapid scaling from prototypes to high-volume runs.

- Double-Sided Assembly: Fully automated reflow profiling ensures optimal solder joint formation for double-sided SMT assemblies, even on high-layer-count, thermally sensitive PCBs.

- Special Process Control: Automated solder paste inspection (SPI) and real-time SPC (Statistical Process Control) ensure defects are prevented at the earliest stage.

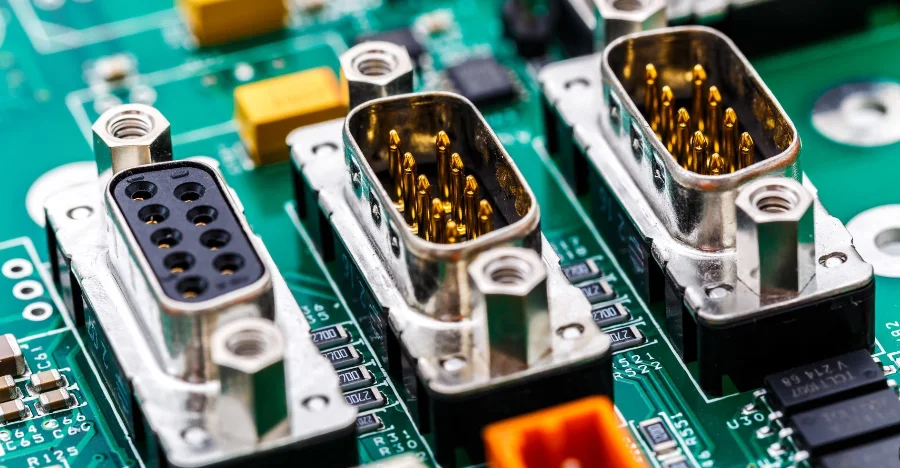

Through-Hole Technology (THT)

We provide both manual and automated THT solutions for power electronics, mechanical assemblies, and high-reliability connectors:

- Selective Wave Soldering: Targeted soldering for THT components without disturbing adjacent SMT areas, critical for mixed-technology boards.

- Press-Fit Assembly: High-force, precision-controlled insertion for backplane and high-current connectors, with automated force monitoring to ensure compliance with manufacturer specs.

- Manual Assembly Excellence: IPC-certified operators perform manual soldering for components requiring specialized handling—such as oversized inductors, custom heatsinks, or legacy through-hole devices.

- Mechanical Integration: Incorporation of transformers, brackets, metal frames, and heavy thermal interfaces within the assembly line process.

Advanced & Specialized Processes

Our advanced assembly capabilities allow us to meet niche industry demands without compromise:

- Rigid-Flex & Flex PCB Assembly: Controlled handling systems and precision fixturing for thin, bendable substrates used in wearables, aerospace avionics, and compact medical devices. Our specialized processes handle rigid-flex PCBs and flexible circuits with precision.

- High-Frequency / RF PCB Assembly: Specialized RF shielding, impedance-controlled soldering, and low-loss connector terminations for high-frequency applications including 5G base stations, radar systems, and satellite communications.

- Conformal Coating & Potting: Spray, dip, and selective coating systems, plus full potting solutions for moisture, vibration, and chemical resistance—ideal for automotive, marine, and defense electronics.

- High Thermal Load Handling: Assembly of heavy copper boards (up to 20 oz) and metal-core PCBs for LED lighting, EV power systems, and industrial motor controllers, with solder alloys and thermal profiles optimized for high-mass components.

- Mixed-Technology Integration: Seamless combination of SMT, THT, press-fit, and mechanical assembly in a single build, reducing handling and improving overall yield.

With this combination of precision, scale, and process flexibility, HILPCB delivers assemblies that not only meet your design specifications but also stand up to the most demanding real-world environments.

4. Assembly Challenges We Solve Every Day

In PCB assembly, most customer concerns go far beyond solder joint quality—they involve on-time delivery, supply chain security, and product reliability over the entire lifecycle. HILPCB's operations are structured to mitigate these risks from the start.

Securing On-Time Delivery Under Tight Schedules

- Capacity Planning: Real-time production scheduling in MES to prioritize urgent builds without disrupting ongoing orders.

- Flexible Line Configuration: SMT lines reconfigurable within hours to switch from prototype to high-volume mode.

- Parallel Processing: PCB fabrication, component kitting, and stencil preparation run concurrently to shorten lead time.

Component Procurement & Supply Chain Risk Management

- Global Sourcing Network: Direct procurement from franchised distributors (Digi-Key, Mouser, Arrow) and vetted local suppliers.

- Shortage Mitigation: Alternative part validation and last-time-buy programs for at-risk components.

- Inventory Buffering: Safety stock for recurring builds, reducing exposure to sudden supply disruptions.

- Compliance with Export/Import Regulations: Adherence to ITAR, EAR, and country-of-origin requirements for sensitive markets.

Maintaining Consistent Quality Across Every Lot

- Lot-to-Lot Repeatability: Locked-down process parameters and verified first-article builds for each order.

- Change Control: Any ECN (Engineering Change Notice) reviewed for production impact and implemented with traceability.

- Environmental and Mechanical Reliability: Optional burn-in, thermal cycling, or vibration testing for products destined for harsh service environments.

Navigating Geopolitical and Regulatory Constraints

- Tariff and Duty Strategy: Multi-region manufacturing options to optimize cost and avoid unnecessary tariffs.

- Market-Specific Certifications: UL, CE, and other regional compliance built into production planning.

- Secure Supply Chains: Controlled storage and handling for defense, medical, and critical infrastructure electronics.

Panelization, Depaneling, and Shipping Integrity

- Panelization Optimization: Balancing assembly efficiency with mechanical stability during transport.

- Precision Depaneling: Laser or routing depaneling to avoid micro-cracks or solder joint stress.

- ESD-Safe Packaging: Moisture barrier bags, desiccants, and shock-resistant cartons to ensure boards arrive production-ready.

By addressing these real-world challenges proactively, HILPCB helps customers avoid costly delays, compliance pitfalls, and field failures—ensuring that every assembly is delivered exactly as promised, no matter the market or complexity.

5. From Quote to Delivery: Our PCBA Workflow

Step 1 — Secure Quote Submission

Upload your BOM, Gerbers, pick-and-place files, and assembly drawings to our portal.

Step 2 — Engineering & Sourcing Review

DFA feedback, component sourcing validation, and cost optimization.

Step 3 — Production & In-Process QC

Automated SMT/THT, inline AOI, and real-time SPC monitoring.

Step 4 — Final Testing & Documentation

X-ray inspection, functional testing, and complete COA/COC traceability.

6. Quality Assurance Without Compromise

At HILPCB, quality is built into every stage of the assembly process—not inspected in at the end. From incoming material verification to final functional testing, every order is subject to documented procedures, IPC-compliant workmanship standards, and full traceability

Our inspection framework combines inline process control and end-of-line verification

Beyond inspection, we maintain comprehensive quality documentation and certification compliance for every lot produced. All assemblies are traceable to their component source, process parameters, and operator IDs, with Certificates of Conformance (COC) and detailed inspection reports available upon shipment. Our quality management system is certified to ISO 9001:2015 and IATF 16949, and all operators are trained to IPC-A-610 Class 2/3 workmanship standards, guaranteeing that your assemblies are not only built right but are also fully compliant with your industry's regulatory and reliability requirements.

7. Industry Applications & Expertise

We serve customers in:

- Automotive — ADAS, EV BMS, infotainment modules.

- Medical — Diagnostic analyzers, imaging systems, patient monitors.

- Telecom & Networking — 5G infrastructure, optical networking boards.

- Industrial & IoT — Robotics, process control, predictive maintenance devices.

- Aerospace & Defense — High-reliability mission-critical electronics.

8. Why HILPCB Is the Right Assembly Partner

- End-to-End Service — PCB fabrication + component sourcing + assembly + testing through our comprehensive turnkey assembly solutions.

- Scalable Production — 1 unit to 1,000,000 units/year.

- Speed — Prototypes in 3—5 days; rush service in 24—48 hours.

- Cost Efficiency — Transparent pricing and design-driven cost reductions.

- Global Support — Localized engineering and supply chain expertise.

Your quote is more than a number—it's the foundation of a successful electronics launch. At HILPCB, we combine technical depth, manufacturing power, and pricing transparency to deliver assemblies that meet your budget, deadline, and performance targets.