You need PCBs manufactured. The local quote came back at $5,000 for 100 boards with three-week delivery. Your Chinese supplier quotes $800 with five-day delivery. But you remember the last offshore disaster—boards arrived with wrong drill sizes, copper delamination, and silk screen that looked like it was printed underwater. Half failed assembly. The "savings" cost you two months and your customer's trust.

China manufactures 60% of the world's PCBs for good reasons: massive capacity, advanced capabilities, and aggressive pricing. But horror stories persist. The difference between success and disaster isn't luck—it's understanding which manufacturers can deliver on their promises and how to specify what you actually need. This guide reveals what separates professional China PCB manufacturing from garage shops with websites, based on manufacturing over 50,000 designs for international customers.

1. The Reality of China PCB Manufacturing Speed

Everyone claims "24-hour quick turn" but few deliver it consistently. Understanding what's actually possible helps set realistic expectations and avoid disappointment when promises meet physics.

What 24-Hour Really Means

True 24-hour turnaround requires your design to be already panelized, use standard materials in stock, and enter a pre-allocated express production slot. This works for:

- 2-4 layer FR4 boards with standard thickness (1.6mm)

- Minimum 6/6mil trace/space (0.15mm)

- Standard finishes (HASL, ENIG)

- No special requirements (impedance control, buried vias, etc.)

Anything beyond these parameters pushes into 48-72 hour territory. Complex boards need time for proper PCB design review and process setup.

The Express Premium Math

Express manufacturing costs 50-200% more than standard delivery. For prototype quantities, this might mean $200 extra to save five days. For production runs, it could mean thousands in premiums. Calculate whether faster boards generate enough value to justify the cost. Sometimes waiting three extra days saves enough to fund the next prototype spin.

Reality Check on Complex Boards

HDI boards with microvias need sequential lamination—each buildup layer requires separate processing. No amount of money makes physics work faster. Flex and rigid-flex boards require specialized materials and processes that can't be rushed without compromising quality. High-frequency boards using Rogers materials need careful handling and controlled processes that standard express lines can't accommodate.

Working with an experienced PCB manufacturer means getting honest timelines upfront rather than optimistic promises that lead to delays.

2. Navigating Material Availability and Substitutions

You specified Rogers RO4350B for your RF design. The boards arrive using a "equivalent" material that has different dielectric constant, ruining your carefully tuned antennas. This scenario plays out daily when customers don't understand material sourcing in China.

The Stock vs. Special Order Trap

Standard FR4, aluminum substrates, and common flexcore materials stay in stock at major manufacturers. Specialized materials like specific Rogers variants, Taconic RF substrates, or high-temperature polyimides often require special orders with 2-3 week lead times. Some suppliers substitute "equivalent" materials without asking. Others wait until after you've paid to mention the three-week material delay.

Protecting Against Substitution

Explicitly state "no substitutions without written approval" in your purchase order. For critical materials, request the material batch number and manufacturer's certificate. Specify key parameters (Dk, Df, Tg) rather than just brand names, but also insist on the exact specified material. Consider ordering extra raw material yourself and consigning it for critical projects—this ensures you get exactly what you designed for.

Understanding Regional Material Differences

Chinese-manufactured FR4 from Shengyi or Kingboard performs differently than European Isola or American Park Electrochemical materials. For most applications, the differences are negligible. For controlled impedance or high-speed designs, these variations matter. Professional PCB services providers maintain material libraries with actual measured values, not just datasheet specifications.

3. Quality Control That Actually Works

Adding "100% E-test" to your order doesn't guarantee quality. Understanding how Chinese manufacturers actually perform quality control—and what they might skip—helps you specify meaningful requirements.

The Inspection Reality

Most manufacturers perform automated optical inspection (AOI) after etching and basic electrical testing before shipping. But "basic" might mean checking only for opens and shorts, missing impedance testing, microsection verification, or thorough visual inspection. Low-cost suppliers skip steps to maintain margins.

Specifying Meaningful QC Requirements

Instead of generic "high quality" requirements, specify measurable criteria:

- Impedance testing with reports for controlled impedance boards (specify test points)

- Microsection photos for via reliability (especially for HDI or high-layer-count boards)

- Ionic contamination testing for medical or high-reliability applications

- X-ray inspection for blind/buried vias with provided images

- Solder mask adhesion testing per IPC-TM-650

Request actual test reports, not just certificates of conformance. Professional manufacturers provide detailed reports without additional charges.

The Batch Consistency Challenge

Your prototype worked perfectly, but production boards from the same supplier fail at 30% rate. What changed? Possibly everything—different operators, equipment, or even factories. Large Chinese manufacturers might have multiple facilities. Your prototype ran in the advanced facility, but production moved to the standard facility. Specify that all orders must be manufactured at the same facility with consistent processes.

Integration with proper PCB assembly preparation includes baking boards to remove moisture, checking for warpage, and verifying surface finish quality before component placement.

4. Advanced Capabilities: Separating Real from Marketing

Every Chinese PCB manufacturer website shows impressive capabilities: 2/2mil line/space, 50-layer boards, any-layer HDI. But having the equipment and successfully manufacturing your design are different things.

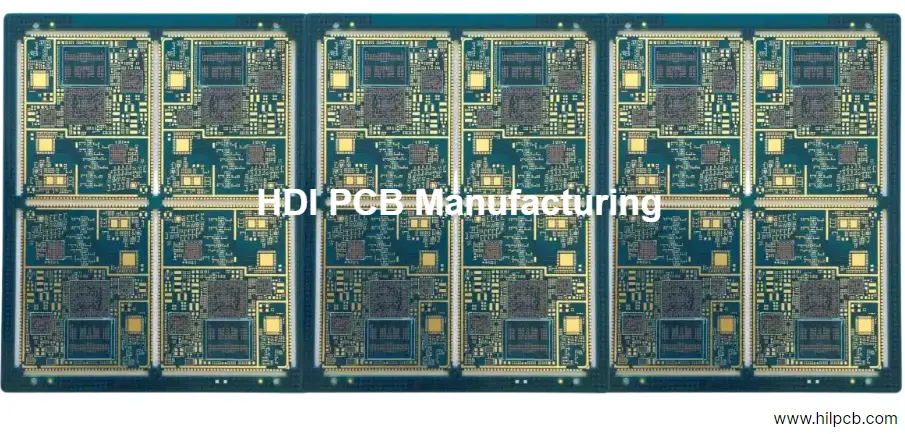

HDI Manufacturing Reality

True HDI capability requires laser drilling equipment, sequential lamination presses, and experienced engineers. Many suppliers outsource HDI to other factories, adding time and cost while reducing control. Indicators of real HDI capability:

- In-house laser drilling (CO2 and UV)

- Sequential lamination equipment on-site

- Ability to build stacked and staggered microvia structures

- Experience with specific via fill types (copper fill, resin fill, silver fill)

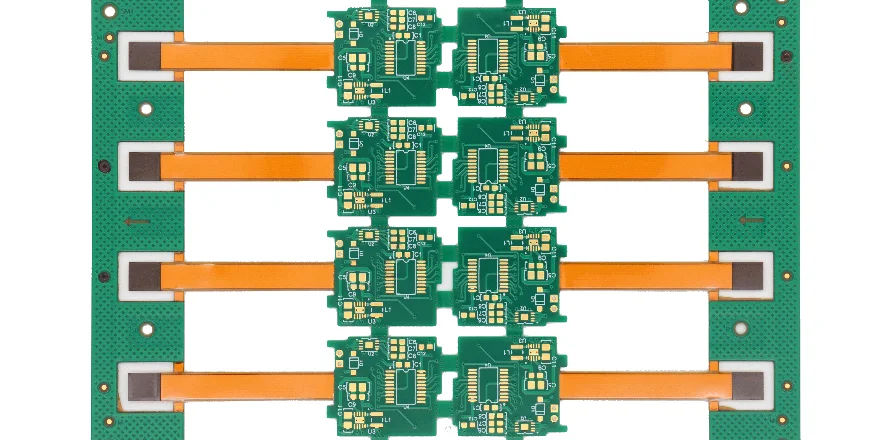

Flex and Rigid-Flex Complexity

Flex PCB manufacturing requires different equipment and expertise than rigid boards. Dynamic flex applications need specialized polyimide materials and adhesive systems. Many "flex manufacturers" can only handle simple static flex applications. For complex rigid-flex with multiple flex zones or bookbinder constructions, verify actual past projects, not just capability claims.

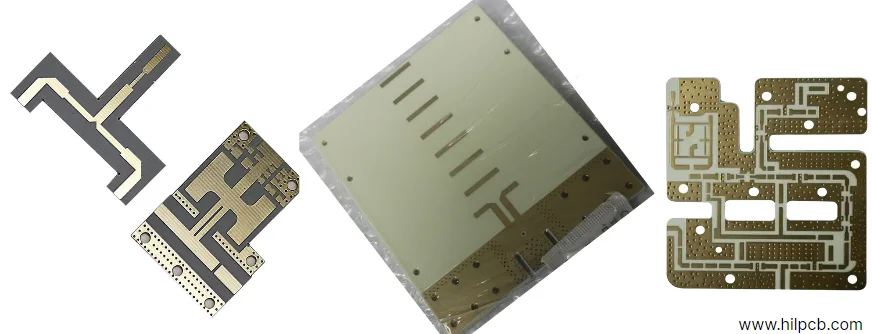

High-Frequency and RF Expertise

Having Rogers materials available doesn't equal RF manufacturing expertise. Proper RF board manufacturing requires:

- Controlled environment to prevent moisture absorption

- Special drilling parameters to prevent PTFE smearing

- Modified lamination cycles for PTFE materials

- Experience with mixed dielectric builds

- Understanding of copper surface preparation for high frequencies

Ask for impedance modeling data and past performance at your specific frequency range. A manufacturer experienced with 2.4GHz WiFi boards might struggle with 77GHz automotive radar.

5. Communication and Project Management

The biggest failures in China PCB manufacturing stem from communication gaps. Your definition of "urgent" might differ from your supplier's. "No problem" might mean "I don't understand but don't want to lose the order."

Engineering Communication That Works

Provide complete documentation upfront:

- Gerber files in RS-274X format with clear layer identification

- Explicit fabrication notes covering every non-standard requirement

- 3D renderings or photos for complex mechanical requirements

- Clear acceptance criteria for critical parameters

Insist on engineering review before production starts. Professional manufacturers provide detailed DFM feedback within hours. If your supplier immediately accepts complex designs without questions, worry.

Managing Time Zone Challenges

China operates 12-16 hours ahead of US time zones. Email exchanges can take days for simple clarifications. Establish clear communication protocols:

- Single technical point of contact

- Response time expectations

- Escalation procedures for urgent issues

- Use of collaboration tools that timestamp and track communications

Setting Realistic Expectations

Chinese holidays can shut down factories for 1-2 weeks. Typhoon season affects southern China shipping. Power restrictions might limit production capacity. Professional PCB production facilities maintain buffer capacity and communicate potential delays proactively, but smaller suppliers might not mention issues until after deadlines pass.

6. Certifications That Matter vs. Paper Tigers

Every Chinese PCB manufacturer displays certification logos. But certifications from unknown agencies mean nothing, and even legitimate certificates might be expired, forged, or belong to a different factory entirely.

Verifying Critical Certifications

- ISO 9001: Check the issuing body and verify on their website

- UL Certification: Use UL's online database to verify active status

- IATF 16949 (Automotive): Confirm scope includes PCB manufacturing, not just trading

- ISO 13485 (Medical): Verify the specific facility location is covered

- AS9100 (Aerospace): Check OASIS database for current certification

Request copies of current certificates and verify independently. Legitimate manufacturers welcome verification.

Understanding Certification Scope

A company might have ISO 9001 for their main facility but manufacture your boards at an uncertified satellite facility. Certifications might cover rigid boards but not flex. Medical certification might apply only to specific processes, not all products. Always confirm your specific requirements fall within certification scope.

Why Choose HILPCB for Your Manufacturing Needs

HILPCB operates as a vertically integrated manufacturer controlling every process from PCB prototyping through volume production. Our Shenzhen facility combines advanced equipment with experienced engineering support to deliver consistent quality across all order sizes.

Transparent Capabilities

- Real 24-hour turnaround for qualifying designs (clearly defined parameters)

- In-house HDI, flex, and rigid-flex manufacturing (not outsourced)

- Extensive materials inventory including Rogers, Taconic, and Arlon

- English-speaking engineering support in your time zone

- All certifications independently verifiable

Quality Commitment

- 100% electrical testing with detailed reports

- Impedance testing included for controlled impedance designs

- Microsection analysis for via reliability verification

- Full traceability from raw materials through shipping

- Zero-defect guarantee with rapid replacement commitment

As a professional PCB company focused on international customers, we understand the challenges of offshore manufacturing and have built our processes to address them directly.

Frequently Asked Questions

Q1: How can I verify a Chinese PCB manufacturer is legitimate before ordering? Request business license verification, check Alibaba Gold Supplier status and years, verify certifications independently, ask for customer references in your country, and start with small prototype orders before committing to production. Legitimate manufacturers welcome verification and provide documentation readily.

Q2: Should I use a trading company or direct manufacturer? Direct manufacturers control quality and timelines better, but require minimum orders and longer relationships. Trading companies offer flexibility and handle logistics but add margin and reduce control. For consistent needs over time, direct relationships work better. For varied requirements, traders provide convenience.

Q3: How do I handle intellectual property concerns with Chinese manufacturers? Split sensitive designs across multiple suppliers, use code names instead of product descriptions, file Chinese patents for truly critical IP, work with established companies with reputations to protect, and consider local assembly of critical components. Most PCB designs aren't worth stealing, but precautions make sense for revolutionary products.

Q4: What's the minimum order quantity reality for Chinese PCB manufacturers? Marketing says "1 piece MOQ" but reality differs. True capabilities typically require:

- Prototype: 5-10 pieces minimum for reasonable pricing

- Small batch: 50-100 pieces for production processes

- Volume: 500+ pieces for best pricing and priority Below these quantities, you're paying for machine setup time regardless of piece count. Group orders or accept longer lead times for better economics on small quantities.