Choosing a PCB company determines product success trajectory. The right partner accelerates development, solves problems proactively, and enables innovation. The wrong choice creates endless firefighting—quality issues, delivery failures, communication breakdowns, and technical limitations constraining design evolution.

Many companies approach PCB provider selection as price comparison exercise, missing strategic value from deep partnerships. Full-service PCB companies function as engineering organization extensions, contributing expertise complementing internal capabilities. Turnkey PCB companies simplify supply chain but vary dramatically in component sourcing quality. Contract PCB companies scale from prototypes to production but differ in process consistency. Reliable PCB companies deliver predictably, batch after batch.

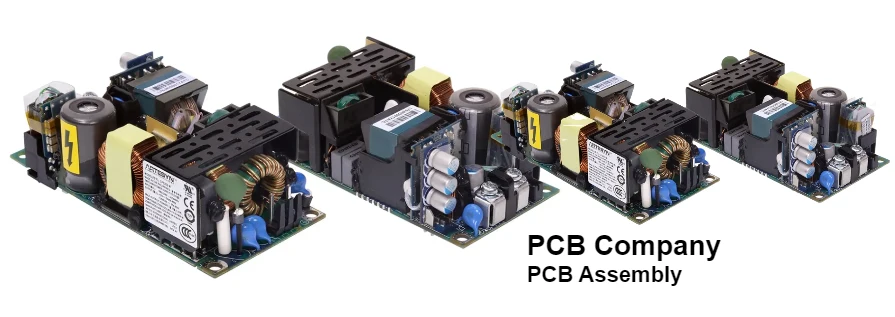

HILPCB operates as a comprehensive China PCB company providing end-to-end electronics manufacturing solutions. Our service model integrates PCB Design support, PCB Fabrication (2-64 layers, all materials), PCB Assembly services (SMT/through-hole), component sourcing, testing, and production scaling—all under one roof with seamless coordination.

Understanding PCB Company Service Models

PCB companies range from narrow specialists to comprehensive solution providers. Service scope determines partnership fit across different PCB Manufacturing requirements.

Fabrication-Only Companies:

- Scope: Produce unpopulated circuit boards from design files

- Value: Specialized process expertise, potentially lower fabrication costs

- Customer responsibility: Separate coordination for assembly, component procurement

- Best for: Companies with established assembly operations or preferring supply chain control

Fabrication + Assembly Companies:

- Scope: PCB manufacturing plus SMT/through-hole assembly services

- Value: Reduced vendor management, optimized fabrication-assembly integration

- Models: Turnkey (company sources materials) or consignment (customer provides components)

- Best for: Most electronics companies seeking streamlined supply chain

Full-Service PCB Companies:

- Scope: Design support, prototyping, fabrication, assembly, testing, supply chain management

- Value: Single-source accountability for complete solution, engineering partnership

- Services: DFM analysis, design optimization, failure analysis, ongoing technical support

- Best for: Companies requiring technical collaboration and comprehensive solutions

Value-Added Providers: Beyond basic manufacturing, some companies offer:

- Design services (schematic capture, PCB layout, SI analysis)

- Program management (dedicated support for complex projects)

- Supply chain management (component sourcing, obsolescence monitoring, inventory programs)

- Logistics support (kitting, box-build, fulfillment services)

Evaluating Technical Capability & Quality Systems

Service breadth matters little without underlying technical competence. Rigorous capability evaluation prevents costly mismatches across PCB Services requirements.

Manufacturing Technology Assessment:

- Layer count capability: Standard (2-16 layers) vs advanced (18-64 layers)

- HDI expertise: Microvia technology, build-up layer count, any-layer structures

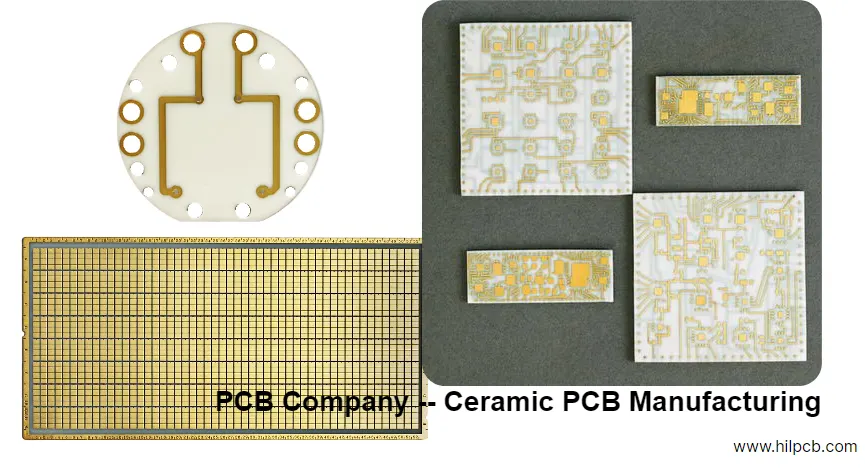

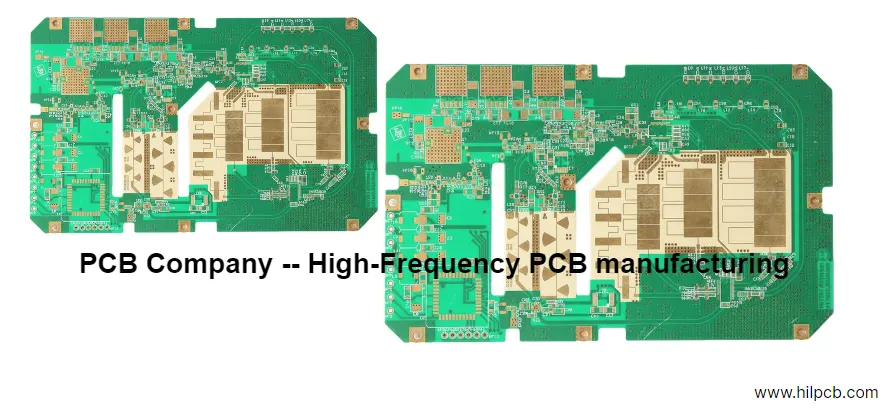

- Specialty materials: Experience with Rogers, Taconic, polyimide, metal core, ceramics

- Precision capabilities: Minimum trace/space (2/2mil vs 3/3mil), aspect ratios, registration accuracy

- Request verification: Board examples showing actual production, not just spec sheets

Assembly Capability Verification:

- Component handling: Fine-pitch capability (01005 components, 0.3mm BGAs), package diversity

- Process technologies: Reflow profiling expertise, selective soldering, conformal coating

- Testing infrastructure: AOI, X-ray, ICT, flying probe, functional testing

- Volume flexibility: Can handle prototype quantities through high-volume production

Quality Certifications:

- ISO 9001: Baseline quality management system

- Industry-specific: AS9100 (aerospace), ISO 13485 (medical), IATF 16949 (automotive)

- IPC standards: IPC-A-600, IPC-6012, IPC-A-610 compliance

- Verify authenticity: Request certificate copies, check registration with issuing bodies

Engineering Support Depth:

- DFM analysis: Comprehensive review before fabrication commitment

- Material consultation: Recommendations based on application requirements

- Problem-solving collaboration: Root cause analysis, corrective action implementation

- Design services: Optional schematic/layout services for complete solution

Our modern PCB Factory infrastructure provides the foundation for reliable, high-quality manufacturing operations.

Business Relationship Factors Beyond Technical Capability

Technical competence necessary but insufficient. Sustainable partnerships require business practices supporting long-term collaboration through experienced PCB Manufacturer operations.

Financial Stability & Business Continuity:

- Company longevity: Years in operation demonstrate market viability

- Growth trajectory: Expanding operations indicate healthy business

- Equipment investment: Recent capital investment shows capability advancement commitment

- Facility ownership: Owned vs leased facilities suggest commitment level

Communication & Responsiveness:

- Account management: Dedicated contacts responsible for your account

- Technical support access: Direct communication with engineers, not just sales

- Response time standards: Same-day or next-day inquiry responses

- Language capability: Effective communication in your working language

- Time zone considerations: Alignment for real-time collaboration when needed

Transparency & Honesty:

- Realistic schedules: Honest lead times rather than optimistic commitments

- Capability disclosure: Admits limitations rather than accepting impossible requirements

- Problem communication: Proactive notification of issues rather than hiding problems

- Cost transparency: Clear pricing without hidden charges

Supply Chain Management:

- Component sourcing: Relationships with authorized distributors

- Inventory programs: Consignment, vendor-managed inventory options

- Obsolescence monitoring: Proactive component lifecycle management

- Material availability: Stock levels for common materials, procurement capability for specialty

Strategic Value: Partnership vs Transactional Vendor

Difference between partners and vendors becomes clear when challenges arise. Strategic companies provide value transcending per-unit pricing across PCB Prototyping and PCB Production phases.

Proactive Design Support:

- Early-stage consultation: Technology selection guidance during design phase

- Feasibility analysis: Identifies manufacturing challenges before layout begins

- Cost optimization: Suggests design alternatives balancing performance and manufacturability

- Stackup design: Collaborates on layer arrangement for signal integrity

Prototype-to-Production Transition:

- Production-intent prototyping: Uses production processes for valid testing

- Process documentation: Develops manufacturing work instructions

- Yield optimization: Refines processes to improve first-pass success

- Volume pricing: Provides production cost estimates for planning

Problem-Solving Partnership:

- Failure analysis: Root cause investigation using cross-sections, electrical testing

- Corrective action: Implements process changes or recommends design modifications

- Design collaboration: Works through challenges to optimize solutions

- Continuous improvement: Data-driven process optimization

Supply Chain Collaboration:

- Component obsolescence management: Monitors lifecycle, recommends alternatives

- Lead time management: Works with forecasts to ensure material availability

- Inventory programs: Holds stock for production programs

- Value engineering: Identifies cost reduction opportunities without compromising performance

Quality Commitment & Performance Metrics

PCB company quality culture determines whether defects are viewed as costs or improvement opportunities through comprehensive PCB Solutions approaches.

Quality System Maturity:

- Certification foundation: ISO 9001, industry-specific standards

- Process control: Statistical monitoring of critical parameters

- Preventive maintenance: Scheduled equipment servicing

- Traceability: Material and process documentation systems

Continuous Improvement Programs:

- Corrective action systems: Formal defect investigation and prevention

- Yield tracking: Monitors first-pass success rates

- Customer feedback integration: Uses complaints and suggestions for improvement

- Employee involvement: Quality culture throughout organization

Performance Measurement:

- On-time delivery rate: Percentage of orders shipped as promised

- First-pass yield: Boards passing inspection without rework

- Defect rate: Parts per million (PPM) defects in shipped product

- Customer return rate: Field failures per thousand boards shipped

Data Transparency:

- Quality reports: Periodic summaries of key metrics

- Process capability studies: Statistical demonstration of control

- Incident reports: Detailed documentation of significant issues

- Trend analysis: Long-term performance visibility

HILPCB Company Excellence

Comprehensive Service Capabilities:

- Design support: DFM analysis, material selection, stackup optimization

- Rapid prototyping: 24-48 hour quick-turn options

- Volume manufacturing: Scalable fabrication from prototypes to thousands

- Turnkey assembly: Complete SMT/through-hole services with testing

- Program management: Dedicated support for complex projects

Advanced Technical Expertise:

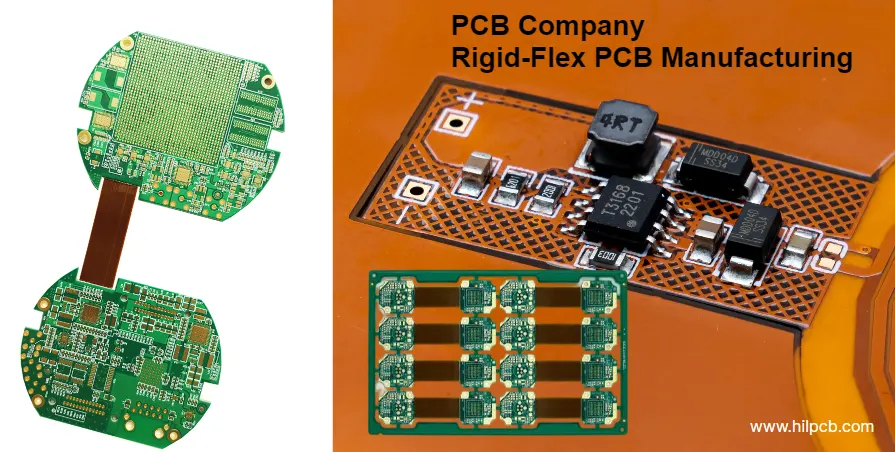

- Complex constructions: 40-layer multilayer, HDI, rigid-flex

- Specialty materials: Rogers, polyimide, PTFE, metal core, thick copper

- Precision processes: 2/2mil traces, controlled impedance ±3Ω, high aspect ratios

- Quality systems: ISO 9001, AS9100, ISO 13485, IATF 16949 certified

Engineering Partnership Approach:

- Proactive consultation: Early-stage design guidance

- Problem-solving collaboration: Root cause analysis, corrective action

- Continuous improvement: Data-driven process optimization

- Long-term relationships: Customer success as primary metric

Business Reliability:

- Established track record: Years of electronics manufacturing experience

- Modern facility: Advanced equipment with comprehensive environmental control

- Financial stability: Ongoing investment in capability expansion

- Responsive communication: Dedicated account management, engineering support

Supply Chain Management:

- Component sourcing: Turnkey procurement with authorized distributors

- Inventory programs: Consignment and vendor-managed options

- Obsolescence monitoring: Proactive component lifecycle management

- Logistics support: Flexible shipping and delivery options

From concept through production, HILPCB provides comprehensive capabilities and partnership approach defining a strategic PCB company relationship focused on quality, innovation, and mutual growth.

Frequently Asked Questions

Q1: What's the difference between a PCB company and a PCB manufacturer? "PCB manufacturer" specifically refers to fabrication capability. "PCB company" broadly includes any business providing PCB services: manufacturing, design, assembly, testing, supply chain. Full-service PCB companies offer comprehensive solutions positioning themselves as strategic partners rather than just manufacturing vendors.

Q2: Should I choose a turnkey or consignment PCB company? Turnkey companies source all components—simplifies management but adds procurement margin. Consignment means you supply components—offers cost transparency but requires inventory management. Partial turnkey balances both. Choose based on: existing component suppliers, procurement expertise, cost visibility needs, and management overhead preference.

Q3: How do I evaluate a China PCB company for reliability? Verify certifications with issuing organizations (ISO 9001, AS9100, ISO 13485, IATF 16949). Request board samples and customer references. Conduct trial orders before production commitment. Check financial stability (years in business, equipment investment). Evaluate communication quality (English proficiency, technical understanding, response time). Virtual or in-person facility tours validate capabilities.

Q4: What questions reveal whether a PCB company is a good long-term partner? Ask about engineering support: Do you provide DFM analysis? Can I speak with technical staff? How do you handle design challenges? Explore problem-solving: What's your process for investigating defects? Provide yield improvement examples? Assess communication: What's typical response time? How do you handle urgent situations? Examine business stability: How long in business? Recent equipment investments? Discuss continuous improvement: How do you track quality metrics?

Q5: How does working with a full-service PCB company differ from managing multiple vendors? Full-service eliminates coordination overhead between fabrication, assembly, component sourcing. Single point of accountability for complete solution. Optimized workflows reduce cycle time. Engineering support spans all aspects. However, costs may be higher than separately-sourced components. Best for: most projects benefiting from simplified management and integrated expertise. Multiple vendors make sense for: very high volumes with established processes and specialized sourcing requirements.