Scaling from prototype to production reveals hidden challenges that destroy margins and delay launches. While prototypes work in quantities of 10, mass PCB production at thousands of units exposes process variation, yield issues, and cost structures that weren't visible in small batches. High-volume PCB production requires statistical process control, automated testing, and supply chain management that prototype shops cannot provide.

The gap between low-volume and production capability determines business success. Contract PCB production needs consistent quality across batches. Industrial PCB production must maintain tight tolerances at scale. Automotive PCB production demands IATF 16949 compliance and PPAP documentation. Consumer electronics PCB production balances cost optimization with reliability. Medical device PCB production requires ISO 13485 traceability.

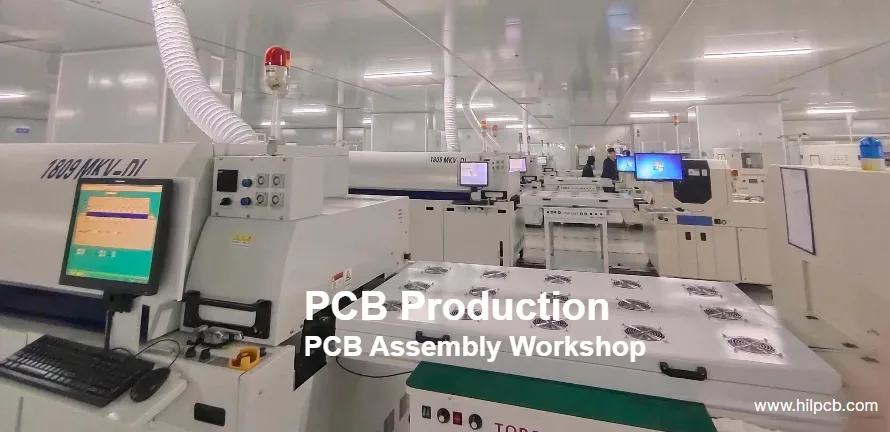

HILPCB provides scalable China PCB production from PCB Prototyping quantities to millions of boards annually. Our production capabilities include volume PCB Manufacturing with statistical process control, automated PCB Assembly and testing, flexible capacity (50-50,000+ boards/month), supply chain management, and seamless prototype-to-production transitions.

Production Volume Capabilities & Scalability

Our China PCB production facility as a comprehensive PCB Company handles complete volume spectrum with optimized processes for each scale.

Production Volume Ranges:

- Prototyping & Small Batch: From a few pieces up to several hundred boards per order, ideal for design validation and pilot runs.

- Low-to-Medium Volume: Typically hundreds to tens of thousands of boards, suited for industrial electronics, medical, and telecom applications.

- High Volume: Tens of thousands to hundreds of thousands of boards, supporting consumer electronics and automotive supply chains.

- Mass Production: Millions of boards annually, with scalable lines serving global OEM brands.

Scalable Manufacturing Processes:

- Panel utilization optimization: maximizes boards per panel, reduces waste

- Automated production lines: minimizes manual handling, improves consistency

- Multi-up panelization: produces multiple boards per panel for efficiency

- Continuous flow manufacturing: reduces cycle time, improves throughput

Capacity Management:

- Dedicated production lines for long-term programs

- Flexible capacity allocation for demand fluctuations

- Equipment redundancy prevents production delays

- Planned maintenance schedules maintain uptime

Production Technology Range:

- Standard rigid PCB production: 2-32 layers, FR4 materials

- HDI production: any-layer microvias, fine-pitch assembly

- Flex and rigid-flex production: volume manufacturing of flexible circuits

- Metal core production: aluminum/copper base for LED and power electronics

- Specialty materials: Rogers, Taconic, ceramic substrates at scale

Statistical Process Control & Quality Systems

Production consistency requires continuous monitoring and rapid response to process variation across our modern PCB Factory operations.

Statistical Process Control (SPC):

- Real-time parameter monitoring: trace width, copper thickness, registration

- Control charts: track variation trends before specs are exceeded

- Cpk analysis: quantifies process capability (target >1.33)

- Automated alerts: trigger investigation when out-of-control

- Corrective action systems: prevent recurrence of defects

Process Capability Metrics:

- First-pass yield: percentage passing without rework (target >95%)

- Defect rate: parts per million (PPM) tracking

- On-time delivery: percentage meeting scheduled dates (target >98%)

- Customer return rate: field failures per thousand boards shipped

Quality Management Systems:

- ISO 9001:2015: quality management foundation

- IATF 16949: automotive production requirements

- ISO 13485: medical device manufacturing

- AS9100: aerospace quality standards

- IPC-A-600/6012: workmanship and performance specs

Production Documentation:

- Manufacturing travelers: record process parameters for each lot

- First article inspection (FAI): validates initial production setup

- PPAP documentation: automotive production part approval

- Certificate of conformance (C of C): material and process verification

- Test data packages: electrical results, impedance measurements, dimensional reports

Our comprehensive PCB Fabrication processes ensure consistency from prototype through high-volume production runs.

Production Cost Optimization Strategies

Volume production economics differ dramatically from prototype pricing. Understanding cost drivers enables optimization through advanced PCB Services support.

Material Cost Reduction:

- Volume pricing: negotiated rates with material suppliers

- Panel utilization: optimizes board layout to minimize waste

- Material standardization: reduces inventory complexity

- Alternative materials: cost-effective substitutes where performance allows

Process Efficiency Improvements:

- Automated handling: reduces labor costs, improves consistency

- Cycle time reduction: increases throughput without equipment investment

- Yield improvement: reduces scrap and rework costs

- Lean manufacturing: eliminates non-value-added activities

Supply Chain Optimization:

- Component volume pricing: leverages purchasing power

- Vendor-managed inventory (VMI): reduces carrying costs

- Consignment programs: defers payment until consumption

- Long-term agreements: locks pricing for production stability

Testing & Quality Cost Balance:

- Statistical sampling: reduces test time while maintaining confidence

- Automated testing: faster throughput than manual methods

- Root cause analysis: prevents defects rather than detecting them

- Poka-yoke (error proofing): designs prevent assembly errors

Production Planning & Supply Chain Management

Reliable production requires synchronized material flow and capacity planning coordinated through experienced PCB Manufacturer operations.

Demand Forecasting & Planning:

- Rolling forecasts: 3-12 month visibility enables material planning

- Safety stock: buffers against demand variability

- Lead time management: coordinates material arrival with production schedules

- Capacity allocation: reserves production slots for committed volumes

Material Requirements Planning (MRP):

- Bill of materials (BOM) management: tracks component requirements

- Inventory control: maintains optimal stock levels

- Reorder point calculations: triggers procurement at appropriate timing

- Obsolescence monitoring: proactive notification of end-of-life components

Production Scheduling:

- Work order management: sequences jobs for optimal flow

- Bottleneck management: prevents capacity constraints

- Expedite capability: handles urgent requirements without disrupting schedule

- Delivery coordination: aligns shipments with customer requirements

Supply Chain Risk Mitigation:

- Dual sourcing: prevents single-point failures

- Component allocation management: navigates supply shortages

- Alternative component qualification: enables substitutions when needed

- Buffer stock: protects against supply disruptions

Prototype to Production Transition

Seamless scaling from prototype to volume manufacturing prevents costly surprises through our integrated PCB Design support and manufacturing expertise.

Pre-Production Validation:

- Design for Manufacturing (DFM) review: optimizes for volume production

- Process capability studies: validates processes can meet specifications

- Pilot run: produces 50-200 boards to validate tooling and processes

- Yield analysis: identifies and addresses systematic issues

Production Documentation Development:

- Manufacturing work instructions: documents every process step

- Quality inspection criteria: defines acceptance standards

- Testing procedures: specifies electrical and functional verification

- Packaging and labeling: ensures correct product identification

Tooling & Equipment Preparation:

- Test fixtures: bed-of-nails or flying probe programming

- SMT stencils: optimized apertures for production paste deposition

- Assembly fixtures: ensures consistent component placement

- Handling trays and carriers: protects boards during processing

First Article Inspection (FAI):

- Dimensional verification: confirms finished size and features

- Electrical testing: validates all nets for continuity and isolation

- Microsection analysis: destructive testing validates internal quality

- Functional testing: power-on verification under specified conditions

HILPCB Production Excellence

Volume Production Capabilities:

- Scalable Capacity: From prototypes and small batches to high-volume production reaching millions of boards annually.

- Technology Coverage: Rigid, rigid-flex, flex, HDI, metal core, and boards with specialty materials (e.g., high-Tg, RF, microwave laminates).

- Layer Count: 2 to 64 layers, including sequential lamination and advanced stack-up designs.

- Integrated Assembly: SMT, through-hole, mixed-technology, and turnkey PCB assembly services.

Quality & Reliability:

- Statistical process control on all critical parameters

- ISO 9001, IATF 16949, ISO 13485, AS9100 certified

- First-pass yield >95% for established blog

- On-time delivery >98% performance

Cost Competitiveness:

- China manufacturing cost advantages

- Volume pricing on materials and components

- Optimized processes reduce waste and cycle time

- Flexible business models (turnkey, consignment, partial)

Supply Chain Management:

- Component sourcing from authorized distributors

- Inventory programs (VMI, consignment, buffer stock)

- Obsolescence monitoring and alternative recommendations

- Global logistics coordination

From pilot runs to millions of boards, HILPCB delivers scalable China PCB production with consistent quality, competitive pricing, and reliable delivery. Our comprehensive PCB Solutions approach ensures smooth transitions from development through volume manufacturing.

Frequently Asked Questions

Q1: What's the minimum order quantity for volume PCB production? Low-volume production starts at 50-100 boards. Medium-volume 500+, high-volume 5,000+. Volume pricing typically begins around 500-1,000 boards depending on complexity. Prototype quantities (1-50) available but at higher per-unit cost.

Q2: How does China PCB production pricing compare to domestic manufacturing? China production typically 30-60% lower cost for complex boards due to labor, material procurement, and economies of scale. Lead time may be longer (shipping), but volume production planning accommodates this. Best value for established blog with stable demand.

Q3: What quality certifications are important for production PCB manufacturing? ISO 9001 baseline for quality management. IATF 16949 essential for automotive production. ISO 13485 required for medical devices. AS9100 for aerospace applications. Verify current certificates and recent audit reports, not just claims.

Q4: How long does prototype-to-production transition take? Pilot run validation: 2-4 weeks including tooling and first article inspection. Production ramp-up: 4-8 weeks to full volume depending on complexity and material availability. Early engagement during design phase accelerates transition.