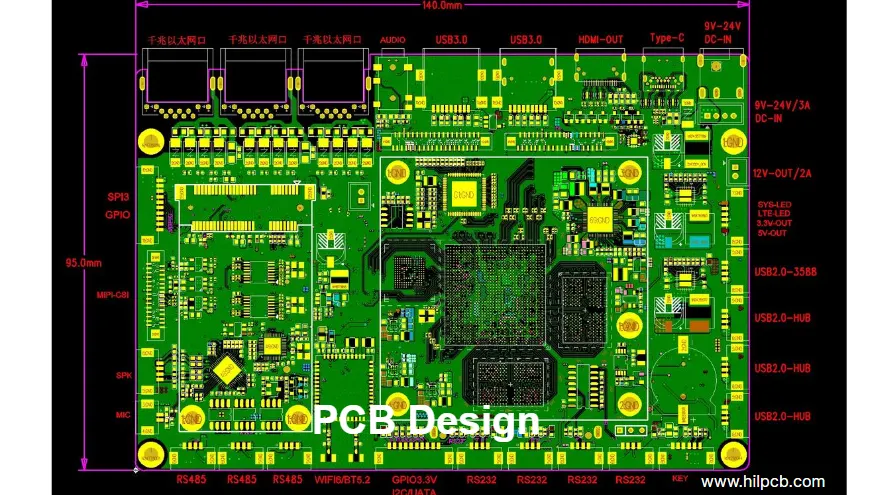

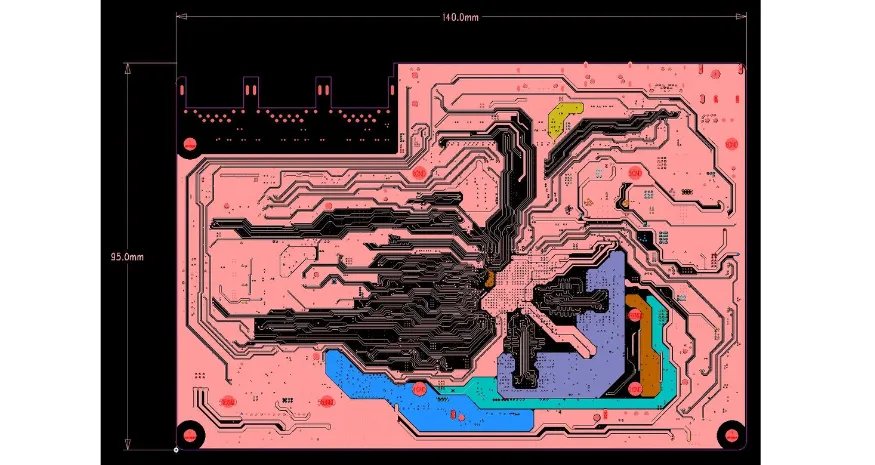

Successful electronics blog start with professional PCB design that balances electrical performance, manufacturability, and cost. While many advertise "PCB design services," few deliver comprehensive expertise: high-speed PCB design for multi-gigabit interfaces, RF PCB design for wireless systems, HDI PCB design for miniaturization, impedance-controlled PCB design for signal integrity, or automotive PCB design meeting IATF standards.

Design failures manifest in manufacturing. High-speed PCB layout without proper termination causes signal integrity issues. RF circuit board design with poor ground planning degrades wireless performance. Power PCB design lacking thermal analysis leads to component failures. Flexible PCB design ignoring bend radius results in copper cracking. Medical device PCB design missing safety isolation creates regulatory failures.

HILPCB provides comprehensive China PCB design services from concept to production-ready files. Our capabilities include high-speed PCB layout (DDR, PCIe, USB, Ethernet), RF and microwave PCB design, HDI routing with microvias, rigid-flex PCB design, DFM analysis, and integrated PCB Fabrication and PCB Assembly services ensuring designs manufacture successfully.

Complete PCB Design Service Capabilities

Our China PCB design team as part of a comprehensive PCB Company handles all circuit board design complexities with expertise across multiple technologies and applications.

Design Service Scope:

- Complete PCB layout: from schematics to fabrication-ready Gerber files

- High-speed PCB design: DDR3/4/5, PCIe Gen3/4/5, USB 3.x/4, 10G+ Ethernet

- RF and microwave design: 5G, WiFi, Bluetooth, GPS, automotive radar, satellite

- HDI PCB layout: any-layer microvias, fine-pitch BGAs, ultra-compact routing

- Rigid-flex design: complex 3D packaging with multiple flex zones

- Power electronics design: heavy copper, thermal management, EMI control

Technology Expertise:

- Layer count: 2-64 layers with optimized stackup design

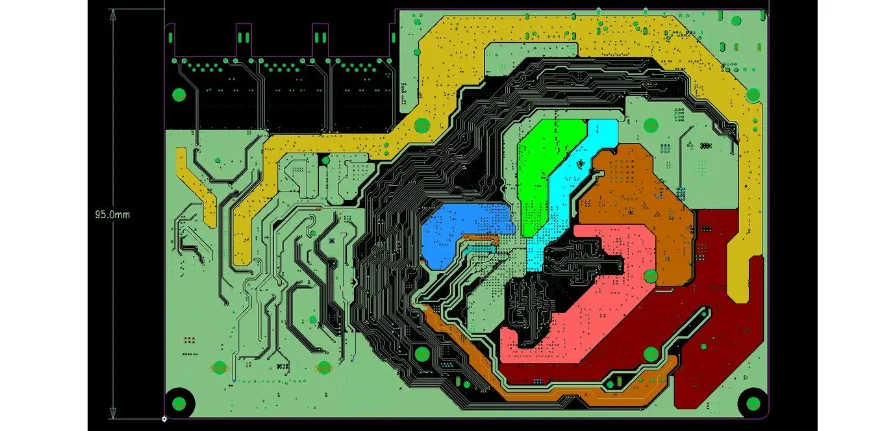

- High-speed design: controlled impedance, differential pairs, length matching

- Component density: fine-pitch BGA escape routing, 0201/01005 placement

- Signal integrity: termination, crosstalk analysis, return path optimization

- Power integrity: decoupling strategy, PDN analysis, voltage drop calculation

- Thermal design: heat spreading, thermal vias, metal core integration

Design Tools & Capabilities:

- CAD software: Altium Designer, Cadence Allegro, Mentor Graphics, KiCad

- SI/PI simulation: HyperLynx, ADS, CST, HFSS for pre-layout verification

- Thermal analysis: Ansys Icepak, thermal simulation for heat management

- 3D mechanical: integration with SolidWorks, STEP models for enclosure fit

- Library management: component footprint creation and verification

High-Speed PCB Design & Signal Integrity

Multi-gigabit interfaces demand specialized high-speed PCB layout expertise beyond standard routing, supported by our advanced PCB Manufacturing capabilities.

High-Speed Interface Design:

- DDR memory: DDR3/DDR4/DDR5 routing with fly-by topology, termination

- PCIe (PCI Express): Gen3/4/5 differential pairs, impedance control ±10%

- USB: USB 2.0, USB 3.x, USB4 with proper termination and shielding

- Ethernet: 1G/10G/25G SerDes, controlled impedance, timing constraints

- HDMI/DisplayPort: differential pairs, length matching, EMI management

Signal Integrity Techniques:

- Controlled impedance: 50Ω single-ended, 85-100Ω differential pairs

- Length matching: intra-pair <5mil, inter-pair matching for timing-critical signals

- Via optimization: back-drilling for stub removal, via-in-pad for density

- Termination: series, parallel, AC coupling capacitor placement

- Crosstalk mitigation: 3W spacing rule, guard traces, orthogonal routing

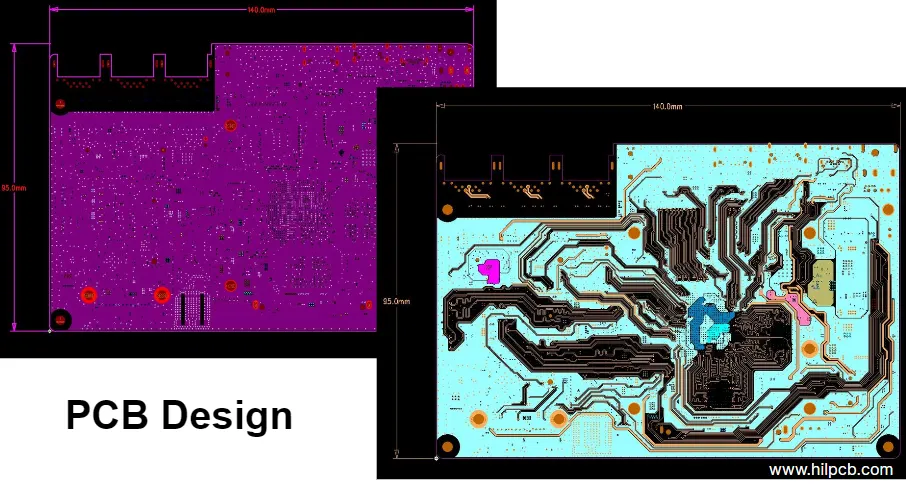

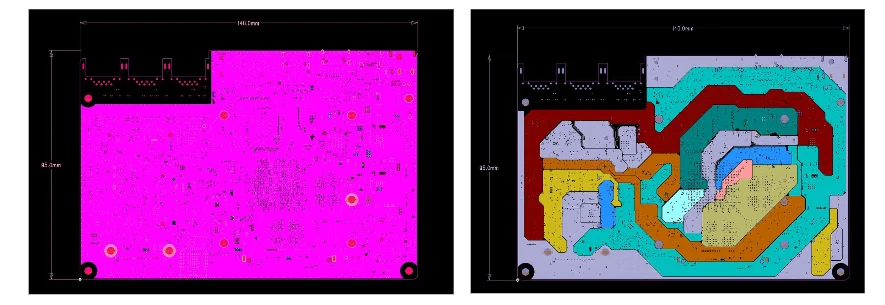

Stackup Design Optimization:

- Reference plane strategy: adjacent ground/power planes for return current

- Layer sequencing: signal-ground-signal-power arrangement

- Material selection: low-loss laminates for high-frequency (Megtron, Isola)

- Dielectric thickness: calculated for target impedance

- Symmetry: balanced stackup prevents warpage

Design Validation:

- Pre-layout SI simulation: validates architecture before routing

- Post-layout verification: checks impedance, crosstalk, timing

- Eye diagram analysis: ensures adequate signal quality margins

- S-parameter extraction: validates transmission line performance

Our engineering team collaborates closely with PCB Prototyping specialists to rapidly validate high-speed designs through iterative testing.

RF & Microwave PCB Design Expertise

Wireless systems require specialized RF circuit board design with strict impedance control and EMI management integrated with our PCB Services infrastructure.

RF Design Applications:

- 5G infrastructure: sub-6 GHz and mmWave (24-40 GHz) front-ends

- Wireless connectivity: WiFi 6/6E/7, Bluetooth, Zigbee, LoRa, NB-IoT

- GPS/GNSS: multi-constellation receivers with antenna integration

- Automotive radar: 24 GHz, 77-81 GHz FMCW radar sensors

- Satellite communications: L-band, Ka-band, phased array antennas

RF Design Techniques:

- Impedance control: 50Ω transmission lines, ±3Ω tolerance

- Material selection: Rogers (RO4003C, RO4350B, RT/duroid), Taconic, Arlon

- Grounding strategy: solid ground plane, via stitching, isolation

- Component placement: minimizes trace length, optimizes signal flow

- Shielding design: EMI cans, keep-out zones, guard rings

Antenna Integration:

- PCB antenna design: inverted-F, patch, loop, chip antenna integration

- Antenna placement: maximizes radiation pattern, minimizes coupling

- Impedance matching: pi/T networks, stub matching for 50Ω

- Ground plane optimization: antenna ground clearance and shape

RF Simulation & Validation:

- EM simulation: ADS, CST, HFSS for 3D electromagnetic analysis

- S-parameter optimization: minimizes insertion loss, maximizes return loss

- Harmonic analysis: identifies spurious emissions

- Far-field pattern: validates antenna radiation characteristics

Design for Manufacturing (DFM) & Cost Optimization

Professional PCB design integrates manufacturability from the start, preventing production issues and controlling costs through our experienced PCB Manufacturer insights.

DFM Analysis Services:

- Automated checking: verifies clearances, drill sizes, aspect ratios

- Manufacturing constraints: validates against fabricator capabilities

- Assembly considerations: component spacing, test point access, rework clearance

- Yield optimization: identifies high-risk features affecting production

Common DFM Issues & Solutions:

- Minimum trace/space violations: adjust to fabricator capability (3/3mil standard)

- Aspect ratio limits: vias too deep for diameter (max 12:1 for standard, 16:1 advanced)

- Annular ring inadequacy: insufficient copper around drilled holes

- Acid traps: acute angles cause etching issues (use 45° or curved)

- Solder mask slivers: inadequate dam between pads causes bridging

Cost Optimization Strategies:

- Panel utilization: board size optimization maximizes boards per panel

- Layer count reduction: consolidates layers where performance allows

- Material selection: uses standard materials unless performance requires specialty

- Via strategy: minimizes blind/buried vias (more expensive than through-vias)

- Surface finish: selects appropriate finish for application (OSP cheapest, ENIG premium)

Design Rule Documentation:

- Fabrication notes: clearly specifies impedance, materials, special requirements

- Assembly drawings: component placement, polarity, orientation

- Stackup documentation: layer arrangement, materials, thickness

- Test point designation: facilitates production testing and debug

Application-Specific Design Services

Different applications require specialized PCB design approaches with unique requirements supported by our PCB Production expertise.

Consumer Electronics PCB Design:

- Smartphone/tablet design: HDI with any-layer microvias, compact routing

- Wearable device design: rigid-flex for 3D packaging, biocompatible materials

- Smart home design: WiFi/Bluetooth integration, cost optimization

- Audio equipment: low-noise analog design, EMI shielding

Automotive PCB Design:

- ADAS sensor design: automotive radar, camera modules, lidar interface

- Powertrain electronics: engine control, transmission control, high-temperature

- Infotainment systems: high-speed interfaces, display drivers, connectivity

- LED lighting: thermal management, driver circuits, automotive-grade components

Industrial & IoT Design:

- Industrial control: extended temperature, noise immunity, rugged design

- IoT device design: low-power optimization, integrated antennas, battery management

- Sensor modules: precision analog, calibration, environmental protection

- Motor control: heavy copper, thermal management, EMI filtering

Medical Device PCB Design:

- Diagnostic equipment: precision analog, noise reduction, safety isolation

- Wearable health monitors: flex circuits, biocompatible, low power

- Implantable devices: miniature rigid-flex, hermetic sealing, sterilization-compatible

- Patient monitoring: medical-grade isolation, EMI compliance, reliability

HILPCB Design Excellence

Complete Design Services:

- Full PCB layout: schematics to Gerber files

- High-speed design: DDR, PCIe, USB, Ethernet

- RF design: 5G, WiFi, Bluetooth, GPS, radar

- HDI routing: microvias, fine-pitch BGAs

- Rigid-flex design: complex 3D packaging

Design Expertise:

- Signal integrity: impedance control, termination, crosstalk mitigation

- Power integrity: decoupling, PDN analysis, thermal design

- EMI/EMC: shielding, filtering, grounding optimization

- DFM integration: manufacturability from design start

Advanced Capabilities:

- SI/PI simulation: pre and post-layout validation

- Thermal analysis: heat spreading and cooling design

- 3D mechanical: enclosure fit verification

- Component selection: optimized for performance and availability

Integrated Services:

- In-house fabrication: ensures designs manufacture correctly

- Assembly services: validates DFA considerations

- Prototyping: rapid iteration for design validation

- Production support: seamless scaling to volume

From concept to production-ready files, HILPCB delivers professional PCB design services with expertise across high-speed, RF, HDI, and rigid-flex technologies, ensuring designs perform reliably and manufacture successfully. Our comprehensive PCB Solutions approach integrates design expertise with manufacturing capabilities. Working within our modern PCB Factory environment enables real-time collaboration between designers and manufacturing engineers.

Frequently Asked Questions

Q1: What's included in complete PCB design services? Full layout from schematics to Gerber files, component footprint creation, stackup design, DFM analysis, fabrication documentation (drill files, assembly drawings, BOM). Advanced services include SI/PI simulation, thermal analysis, and 3D mechanical verification.

Q2: How much do professional PCB design services cost? Simple 2-4 layer designs: $500-2,000. Complex multilayer (8-16 layers): $2,000-8,000. Advanced HDI/rigid-flex/RF designs: $8,000-25,000+. Pricing depends on complexity, layer count, component density, and special requirements. Prototype builds often include design services.

Q3: What's the difference between high-speed PCB design and standard layout? High-speed design requires controlled impedance (±10%), differential pair routing, length matching (<5mil intra-pair), termination strategies, and SI simulation. Standard design focuses on connectivity and basic spacing. High-speed critical above 100 MHz clock rates or multi-gigabit serial interfaces.

Q4: Can you design PCBs using Rogers or other specialty materials? Yes, experienced with Rogers (RO4003C, RO4350B, RT/duroid), Taconic, Arlon, Isola, and other high-frequency materials. Design includes proper impedance calculation for material Dk, modified stackup design, and fabrication-specific considerations for these materials.

Q5: How long does PCB design typically take? Simple designs (2-4 layers, <100 components): 1-2 weeks. Medium complexity (6-8 layers, 200-500 components): 2-4 weeks. Complex designs (12+ layers, HDI, high-speed interfaces): 4-8 weeks. Timeline depends on schematic quality, component selection, and iteration requirements.