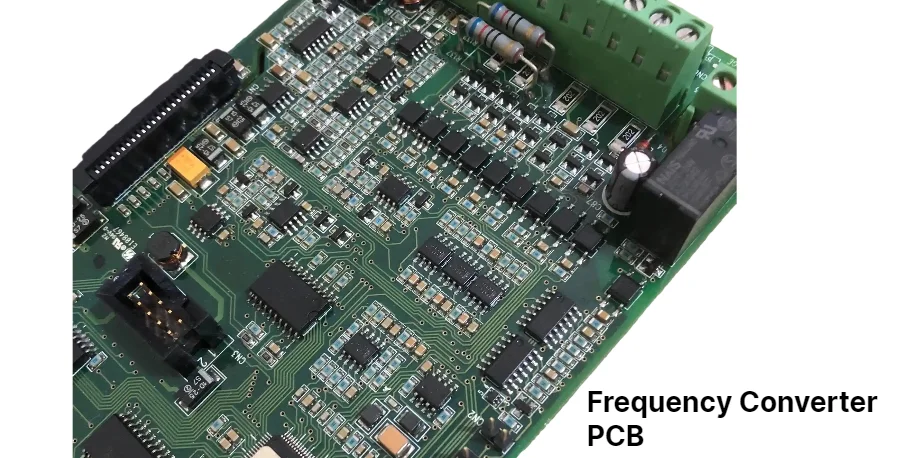

HILPCB is a comprehensive PCB manufacturing and assembly provider, delivering high‑performance boards for industrial power electronics, motor control, and automation systems. While our capabilities include frequency converter PCBs for variable frequency drives, AC‑DC‑AC converters, and power factor correction circuits, we also support a wide range of high‑frequency, multi‑layer, and fine‑pitch PCB projects.

Modern power conversion systems require robust PCB designs that integrate high‑power semiconductors, precision control circuits, and efficient thermal management. HILPCB offers complete services from rapid prototyping to high‑volume production, ensuring reliable performance and scalable manufacturing for diverse industrial applications beyond frequency converters.

Frequency Converter PCB Design Requirements

Frequency converter PCB design integrates multiple technologies including power factor correction circuits, high-power switching devices, and precision control systems. The primary challenges involve managing high currents and voltages while ensuring electromagnetic compatibility and optimal thermal dissipation.

Essential Design Elements:

• Power Factor Correction (PFC): Boost PFC topology with MOSFET or IGBT switching providing high power factor and low harmonic distortion with optimized inductor placement and current sensing

• High-Power Switching Circuits: Advanced power semiconductors handling kilovolt switching with precise gate drive circuits and protection systems ensuring reliable operation

• DC Bus Management: High-capacity filter circuits with low ESR capacitors and voltage regulation maintaining stable DC link voltage for inverter operation

• Motor Drive Interface: Three-phase inverter circuits with current feedback and protection systems enabling precise motor speed and torque control

Frequency converters operate across power ranges from fractional horsepower to megawatt applications. High-frequency PCB substrates maintain signal integrity in switching circuits while supporting complex power routing networks required for high-efficiency operation.

Electromagnetic Compatibility:

Power electronics generate significant electromagnetic interference requiring careful PCB design. Strategic component placement minimizes current loop lengths while dedicated ground planes and shielding techniques contain electromagnetic fields and reduce conducted and radiated emissions.

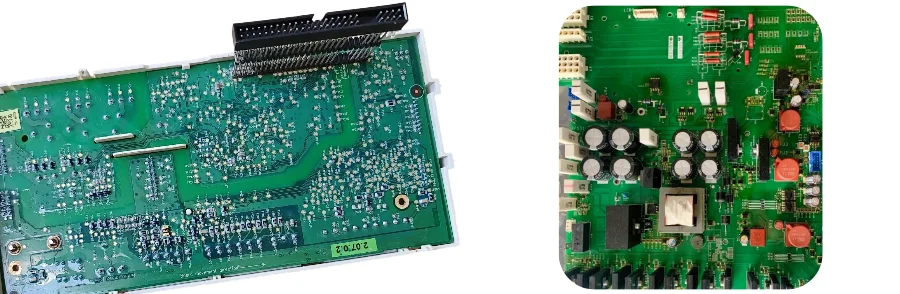

Manufacturing Processes for Power Electronics PCBs

Professional frequency converter PCB manufacturing employs specialized techniques and materials optimized for high-power applications and thermal management. Material selection directly impacts system efficiency, reliability, and operational lifetime in industrial environments.

Advanced Material Selection:

Heavy copper PCB constructions with copper weights from 2 oz to 10 oz enable efficient current distribution for high-power switching circuits. Thick copper layers reduce resistive losses and improve thermal dissipation in power conversion applications.

High-TG PCB materials with glass transition temperatures above 170°C ensure mechanical stability under thermal cycling common in power electronics applications.

Precision Manufacturing:

• Multi-Layer Power Routing: Complex stackups with dedicated power planes, ground planes, and signal layers ensuring optimal current distribution and electromagnetic isolation

• Thermal Via Arrays: High-density thermal via networks conducting heat from power components to internal copper layers and external heat sinks

• Component-Specific Pads: Customized landing patterns for power semiconductors, inductors, and capacitors optimizing thermal and electrical performance

• Quality Control: Comprehensive testing including thermal imaging, impedance verification, and high-voltage isolation testing

Manufacturing processes include controlled drilling for thermal vias, precision etching for high-current traces, and specialized surface finishes ensuring reliable power semiconductor attachment and long-term reliability.

Assembly Solutions for Power Conversion Equipment

Frequency converter PCB assembly requires precision techniques for high-power mixed-signal designs integrating power semiconductors, magnetic components, and control circuits. Assembly processes must ensure optimal performance while maintaining safety and reliability standards.

Critical Assembly Requirements:

SMT assembly processes accommodate power modules, gate drive circuits, and precision sensing components with specialized reflow profiles protecting temperature-sensitive power devices while ensuring reliable solder joints.

Component Integration:

• Power Semiconductors: IGBTs, MOSFETs, and diode modules rated for high voltage and current with optimized thermal interface materials

• Magnetic Components: Custom inductors and transformers designed for specific frequency converter requirements with minimal EMI generation

• Control Systems: Microcontrollers, DSPs, and gate driver circuits providing precise switching control and system protection functions

• Protection Circuits: Overcurrent detection, thermal monitoring, and fault isolation systems ensuring safe operation under all conditions

Thermal Management Integration:

High-power applications require advanced thermal management including heat sink attachment, thermal interface material application, and temperature monitoring systems. Specialized assembly processes ensure optimal thermal conductivity while maintaining electrical isolation requirements.

Assembly validation includes functional testing under rated power conditions, thermal performance verification, and electromagnetic compatibility testing ensuring compliance with industrial standards.

Applications in Industrial Power Systems

Frequency converter PCBs serve diverse applications from motor drives to renewable energy systems, each requiring specific performance optimization and safety considerations.

Variable Frequency Drives:

Motor control applications demand precise speed regulation with high efficiency across wide operating ranges. Backplane PCB designs enable modular VFD systems with hot-swappable power modules ensuring continuous industrial operation.

Servo drive systems require ultra-precise control with fast dynamic response. HDI PCB construction enables compact control circuits while maintaining signal integrity for high-resolution feedback systems.

Renewable Energy Systems:

Solar inverter applications require high efficiency and grid compliance with advanced MPPT algorithms. Wind turbine converters handle variable input power with sophisticated grid synchronization and power quality control.

Industrial Automation:

Manufacturing equipment relies on frequency converters for precision process control including pumps, fans, conveyors, and specialized machinery. Data center applications prioritize efficiency and power density for cooling system optimization.

Professional Manufacturing Services

HILPCB provides comprehensive frequency converter PCB services from design consultation through high-volume production. Our engineering expertise ensures optimal performance while maintaining safety standards and regulatory compliance.

Complete Service Portfolio:

• Design Optimization: Power electronics engineering using advanced thermal simulation and electromagnetic analysis tools for performance validation

• Rapid Prototyping: Quick-turn prototypes with comprehensive power testing and thermal validation for accelerated development cycles

• Volume Manufacturing: Scalable production from prototypes to hundreds of thousands of units with consistent quality and delivery performance

• Testing and Certification: Power performance verification, EMC compliance testing, and safety certification support for global market access

Quality and Compliance:

Turnkey assembly services include component sourcing, assembly, power testing, and packaging with full supply chain management and component traceability.

ISO 9001:2015 and IPC-A-610 Class 3 certifications ensure consistent processes while safety compliance including UL, CE, and IEC standards supports global industrial applications. Pre-compliance testing minimizes certification risks and accelerates time-to-market.

Our partnerships with power component suppliers and testing laboratories provide comprehensive support for motor drive certification, grid compliance, and industrial safety requirements ensuring reliable field deployment.

Frequently Asked Questions About Frequency Converter PCB

Q: What makes frequency converter PCB design different from standard power PCBs?

A: Frequency converter PCBs require specialized power factor correction circuits, high di/dt switching management, thermal via arrays for power dissipation, and electromagnetic compatibility optimization. Critical considerations include current loop minimization, gate drive isolation, and thermal management for high-power semiconductors.

Q: Which materials are best for high-power frequency converter applications?

A: Heavy copper substrates (4-10 oz) provide excellent current carrying capacity while high-TG materials ensure thermal stability. Rogers materials may be used for high-frequency switching circuits while polyimide substrates offer enhanced thermal performance for extreme applications.

Q: How do you ensure electromagnetic compatibility in frequency converters?

A: We implement comprehensive EMC design including dedicated ground planes, strategic component placement, input filtering circuits, and shielding techniques. Pre-compliance testing and design optimization minimize electromagnetic interference while meeting industrial EMC standards.

**Q: What assembly capabilities do you provide for power electronics? **

A: Our services include precision power semiconductor mounting, thermal interface material application, magnetic component integration, and comprehensive power testing. We support both prototype and high-volume production with industrial-grade quality standards and safety compliance.

Q: Can you support both low-power and industrial high-power frequency converters?

A: Yes, we provide complete manufacturing services for frequency converters from fractional horsepower drives to industrial megawatt systems with appropriate optimization for power levels, thermal management, and safety requirements for each application category.