HILPCB is a specialized PCB manufacturer with advanced capabilities in high-precision, multilayer, and high-frequency circuit board production. Our manufacturing and assembly solutions support sophisticated gyroscope applications—including MEMS gyroscope PCBs, inertial measurement units (IMUs), and angular velocity detection systems used in aerospace, automotive, robotics, and navigation industries.

Beyond fabrication, we provide comprehensive PCB assembly services, including ultra-precision SMT for MEMS sensors, fine-pitch BGA placement, controlled impedance routing, and advanced testing protocols—ensuring optimal sensor performance, signal integrity, and long-term stability in critical motion sensing applications.

Our expertise extends across various motion sensing technologies, with specialized processes for gyroscope PCB assembly, inertial navigation electronics, and other precision sensor designs requiring low-noise signal processing, mechanical stability, and exceptional thermal management. From concept to production, HILPCB delivers high-performance gyroscope PCBs with consistent quality and rigorous process control.

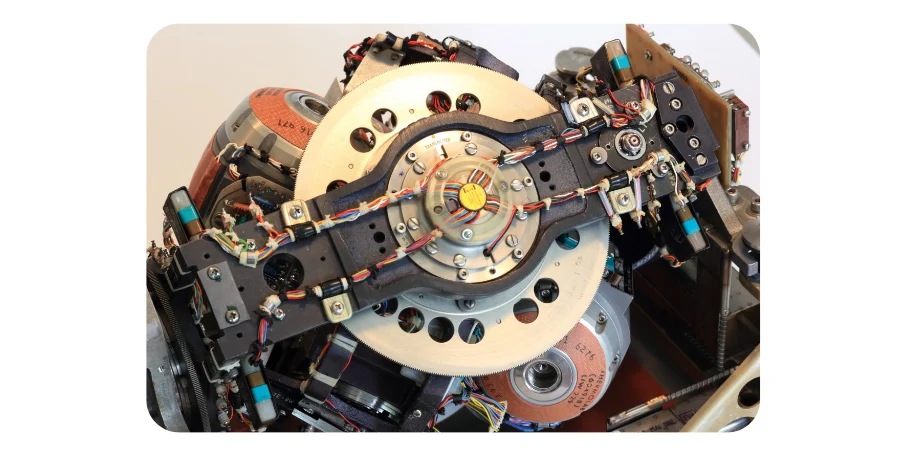

High-Precision Gyroscope PCB Architecture and Design

Developing advanced gyroscope circuit boards demands exceptional expertise in analog signal processing, mechanical isolation, and precision manufacturing. Our comprehensive solutions support:

MEMS Gyroscope Integration and Signal Processing Optimized for ultra-sensitive angular velocity detection, we design PCBs with dedicated analog front-ends, low-noise power distribution, and sophisticated grounding schemes to preserve sensor accuracy and minimize drift in critical navigation applications.

Advanced Multilayer Stackup Design Our multilayer PCB configurations feature controlled impedance routing, dedicated ground planes, and strategic layer assignments that isolate sensitive analog signals from digital processing circuits while maintaining compact form factors.

High-Frequency Signal Integrity Management Utilizing high-frequency PCB design principles, we ensure proper signal routing for carrier frequency demodulation, clock distribution, and high-speed digital interfaces essential for modern gyroscope systems.

Precision Thermal Management Solutions Our high thermal PCB technologies incorporate thermal vias, copper balancing, and temperature-stable materials to minimize thermal drift and maintain calibration accuracy across operational temperature ranges.

We specialize in complex inertial measurement unit (IMU) designs where multiple gyroscopes, accelerometers, and magnetometers are integrated into single-board solutions requiring exceptional mechanical stability and electromagnetic compatibility.

Critical Design Considerations for Gyroscope PCB Systems

Our engineering approach addresses the unique challenges of gyroscope PCB design, where mechanical precision meets advanced electronics for optimal sensor performance:

Ultra-Low Noise Analog Circuit Design Gyroscope signals often exist in the millivolt range, requiring sophisticated noise management techniques including guard rings, split ground planes, and careful component placement to maintain signal-to-noise ratios critical for accurate angular velocity measurements.

Mechanical Stress Isolation and Stability We implement HDI PCB technologies with fine-pitch via structures and stress-relief designs that minimize mechanical coupling between the MEMS sensor and PCB substrate, preventing calibration drift due to thermal expansion or mechanical shock.

Power Distribution Network Optimization Multiple voltage rails with stringent noise specifications require dedicated power planes, local regulation circuits, and comprehensive decoupling strategies. Our designs incorporate low-dropout regulators and precision references essential for stable sensor operation.

Electromagnetic Compatibility and Shielding Advanced grounding strategies, strategic component placement, and EMI shielding techniques ensure gyroscope PCBs maintain performance in electrically noisy environments typical of automotive and industrial applications.

Signal Processing Chain Integration From sensor interface through analog-to-digital conversion to digital signal processing, our designs optimize the entire signal chain for minimal latency, maximum accuracy, and robust performance under varying operational conditions.

Advanced Manufacturing and Quality Control for Gyroscope PCBs

Our specialized manufacturing processes are optimized for the stringent requirements of high-precision gyroscope assemblies:

- Precision Material Selection and Control We utilize high-Tg PCB materials with exceptional dimensional stability and low dielectric loss characteristics, essential for maintaining mechanical tolerances and electrical performance over extended operational periods.

- Ultra-High Precision SMT Assembly Our SMT assembly capabilities include placement accuracy within ±10 micrometers, critical for proper MEMS sensor alignment and maintaining the mechanical relationships required for gyroscope calibration.

- Comprehensive Testing and Validation Every gyroscope PCB undergoes rigorous electrical testing including impedance verification, noise measurements, and functional validation of sensor interfaces. Mechanical testing validates vibration resistance and thermal cycling performance.

- Advanced Inspection and Quality Assurance X-ray inspection verifies internal solder joint quality, while automated optical inspection ensures component placement accuracy. Functional testing validates gyroscope sensitivity, bias stability, and cross-axis coupling characteristics.

- Environmental Stress Screening Temperature cycling from -40°C to +85°C, vibration testing per MIL-STD-810, and humidity exposure validation ensure reliable performance in demanding aerospace and automotive applications.

Gyroscope PCB Applications Across Industries

We manufacture precision gyroscope PCBs for motion sensing and navigation applications across diverse sectors:

Aerospace and Aviation Systems Inertial navigation units, flight control gyroscopes, autopilot systems, attitude reference systems, satellite stabilization platforms, missile guidance systems.

Automotive and Transportation Electronic stability control, rollover detection systems, autonomous vehicle navigation, advanced driver assistance systems (ADAS), vehicle dynamics control, anti-lock braking systems.

Robotics and Industrial Automation Robotic arm stabilization, autonomous navigation systems, industrial platform leveling, precision positioning control, drone flight controllers, automated guided vehicle systems.

Consumer Electronics and Mobile Devices Smartphone orientation sensors, gaming controllers, virtual reality headsets, image stabilization systems, fitness trackers, smartwatch motion detection.

Marine and Offshore Applications Ship navigation systems, offshore platform stabilization, underwater vehicle guidance, marine autopilot systems, vessel motion compensation, dynamic positioning systems.

Defense and Military Systems Tactical navigation units, weapon system stabilization, soldier-worn navigation devices, armored vehicle guidance, unmanned ground vehicle control systems.

Scientific and Research Instruments Seismology equipment, precision measurement instruments, laboratory automation systems, telescope tracking mounts, centrifuge control systems.

Medical and Healthcare Devices Surgical robot stabilization, patient monitoring systems, rehabilitation equipment, prosthetic control systems, medical imaging stabilization.

Energy and Utilities Wind turbine control systems, solar panel tracking mechanisms, pipeline monitoring equipment, power line inspection drones, offshore drilling platform control.

Sports and Recreation Golf swing analyzers, athletic performance monitors, camera stabilization systems, recreational drone controllers, sporting equipment sensors.

We provide customized gyroscope PCB solutions for specialized applications, balancing performance requirements with size, power, and cost constraints across mission-critical and commercial deployments.

Certifications and Compliance for Precision Gyroscope PCBs

HILPCB ensures every gyroscope and motion sensing PCB meets rigorous international standards and compliance requirements. Whether deployed in aerospace navigation systems or automotive safety applications, our boards are manufactured under certified quality systems ensuring reliability, performance, and regulatory approval.

Our comprehensive certification portfolio includes AS9100 aerospace quality management, ISO/TS 16949 automotive standards, IPC Class 3 workmanship for high-reliability applications, and MIL-STD-883 for defense-grade electronics. This multi-standard approach ensures our gyroscope PCBs meet the stringent requirements of safety-critical applications across all industries.

For global market deployment, we maintain full CE, FCC, and RoHS compliance for commercial gyroscope systems, plus specialized certifications for automotive functional safety (ISO 26262) and aviation electronics (DO-160). Our quality documentation includes comprehensive test reports, certificates of conformance, and traceability records supporting both commercial and defense procurement requirements.

We also support ITAR-restricted and export-controlled programs with secure manufacturing processes, controlled material sourcing, and detailed documentation management—ensuring sensitive navigation and guidance system PCBs meet all security and compliance requirements.

Why Choose HILPCB for Your Gyroscope PCB Manufacturing

We deliver comprehensive support beyond standard PCB production, offering complete solutions for your precision motion sensing electronics:

Specialized Expertise in Sensor Electronics Deep knowledge of MEMS sensor interfaces, analog signal processing, and precision manufacturing techniques optimized for gyroscope and inertial navigation applications.

Advanced Manufacturing Capabilities State-of-the-art equipment for ultra-high precision assembly, controlled impedance routing, and environmental testing ensuring consistent performance across production volumes.

Rapid Prototyping to Volume Production Flexible manufacturing approach supporting everything from initial concept validation to high-volume automotive and aerospace production with consistent quality and delivery performance.

Complete Engineering Support Signal integrity analysis, thermal simulation, EMC consulting, and design optimization services for gyroscope PCB performance enhancement and cost reduction.

Full Lifecycle Manufacturing Services Our turnkey assembly approach includes component sourcing, assembly, testing, design revision support, and long-term obsolescence management for sustained product success.

For applications demanding ultimate thermal performance and stability, our ceramic PCB solutions provide superior thermal conductivity and dimensional stability essential for high-precision gyroscope systems.

Gyroscope PCB FAQ

What is a gyroscope PCB? A gyroscope PCB is a specialized circuit board designed to interface with MEMS gyroscope sensors, processing angular velocity signals through low-noise amplification, precise analog-to-digital conversion, and digital signal processing to deliver accurate motion sensing data for navigation and control applications.

Can HILPCB support aerospace-grade gyroscope electronics? Yes. We meet AS9100 aerospace quality standards, IPC Class 3 workmanship requirements, and can support ITAR-compliant manufacturing for defense and aerospace contractors worldwide.

What makes gyroscope PCBs different from standard sensor boards? Gyroscope PCBs require exceptional mechanical stability, ultra-low noise analog circuits, and precise thermal management. We use specialized materials, controlled impedance routing, and stress-isolation techniques to maintain sensor calibration accuracy over extended operational periods.

Do you manufacture complete IMU modules with integrated gyroscopes? Yes. We design and assemble complete inertial measurement units combining gyroscopes, accelerometers, and magnetometers with integrated signal processing, calibration circuits, and communication interfaces suitable for navigation and motion control applications.

Can I order both prototype and production quantities for gyroscope PCBs? Absolutely. We support the complete development lifecycle—from initial prototyping and design validation through high-volume production manufacturing, maintaining consistent quality standards and delivery schedules throughout the product lifecycle.