Highleap PCB Factory (HILPCB) delivers comprehensive PCB First Article Inspection services that bridge prototype development and volume manufacturing through advanced quality validation protocols. Our systematic FAI methodology utilizes flying probe testing, automated optical inspection (AOI), and automated X-ray inspection (AXI) to ensure manufacturing process capability and product conformance before mass production initiation.

Our multi-dimensional inspection approach encompasses materials verification, manufacturing process validation, assembly quality assessment, and statistical capability analysis, providing quantitative evidence that production systems can consistently deliver specification-compliant products while identifying potential issues early in the manufacturing cycle.

Advanced FAI Testing Technologies and Methodologies

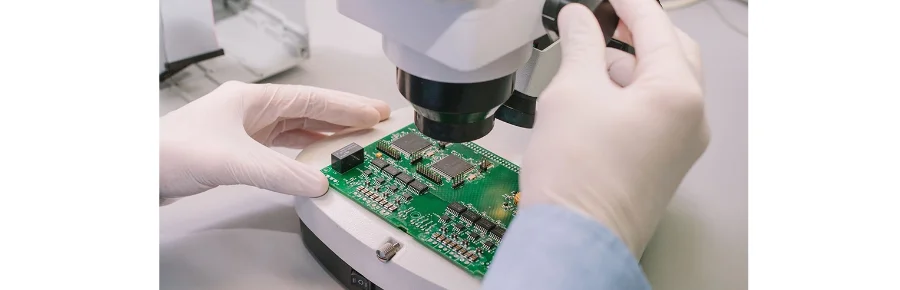

PCB First Article Inspection at HILPCB employs integrated multi-modal inspection technologies that validate critical manufacturing and assembly parameters through precision measurement systems and automated analysis protocols. Our comprehensive approach ensures thorough quality verification across all product characteristics.

Core Inspection Technologies:

• Flying Probe Testing: Automated electrical verification performs continuity analysis, impedance measurement, and parametric testing without custom fixtures, enabling rapid validation of complex HDI PCB and high-frequency PCB designs with micrometer-level probe positioning accuracy • Automated Optical Inspection (AOI): High-resolution imaging systems with machine vision algorithms detect component placement errors, polarity issues, and assembly defects while performing statistical analysis of placement accuracy and solder paste distribution • Automated X-ray Inspection (AXI): Non-destructive analysis evaluates hidden solder joints, BGA connections, and internal assembly quality in multilayer PCB configurations with void detection and joint quality assessment • Precision Measurement Systems: Coordinate measuring machines verify mechanical dimensions, hole positioning, and trace geometries against engineering specifications with statistical process capability analysis

Materials and Process Validation:

Comprehensive material verification includes substrate authentication, surface finish analysis, and component validation through documentation review and analytical testing. For specialized applications requiring rogers PCB or ceramic PCB substrates, validation encompasses dielectric constant measurement and thermal performance characterization.

Manufacturing process validation covers SMT procedure verification, stencil printing analysis, component placement accuracy, and reflow soldering profile confirmation with statistical control parameter establishment for volume production monitoring.

Statistical Process Control and Quality Analysis

Professional PCB First Article Inspection incorporates comprehensive statistical analysis methodologies that establish manufacturing process capability and provide quantitative evidence of quality system effectiveness through industry-standard analytical techniques and measurement system validation.

Process Capability Assessment:

Statistical evaluation establishes process capability indices (Cp, Cpk) for critical characteristics including dimensional tolerances, electrical parameters, and assembly quality metrics. Measurement system analysis (MSA) validates inspection equipment accuracy and repeatability while gauge R&R studies quantify measurement variation and establish confidence intervals.

Control chart implementation utilizes first article data to establish baseline parameters for ongoing production quality monitoring with control limits, specification boundaries, and trending analysis providing early warning indicators for process drift or capability degradation.

Electrical Performance Validation:

Comprehensive electrical testing validates circuit functionality, signal integrity, and parametric performance across all network connections through flying probe analysis. For high-speed PCB applications, validation includes signal integrity analysis, crosstalk measurement, and timing verification with frequency response characterization.

Assembly quality assessment utilizes optical and X-ray inspection for solder joint evaluation, component placement verification, and mechanical connection integrity testing with statistical analysis establishing acceptance criteria and process control parameters.

Digital Documentation and Customer Approval Process

Modern PCB First Article Inspection requires comprehensive digital documentation systems that capture inspection results, statistical analysis, and process validation data in standardized formats compatible with quality management systems and regulatory compliance requirements.

Comprehensive Inspection Reports:

FAI documentation includes detailed measurement results, statistical summaries, photographic evidence, and process capability assessments organized in industry-standard formats. Digital systems provide searchable databases, automated report generation, and complete traceability linking inspection results with production parameters and material certifications.

Flexible Approval Options:

HILPCB provides customized first article approval processes tailored to customer requirements and project complexity:

Option 1: Digital approval utilizing high-resolution photography, detailed inspection reports, and measurement data transmitted through secure electronic systems for basic validation requirements.

Option 2: Physical sample shipment enabling customer facility testing and independent verification for applications requiring enhanced validation protocols or specialized testing procedures.

Customer-specific validation requirements are accommodated during quotation processes to optimize approval efficiency and ensure compliance with project timelines and quality specifications.

Advanced Quality Infrastructure at Highleap PCB Factory

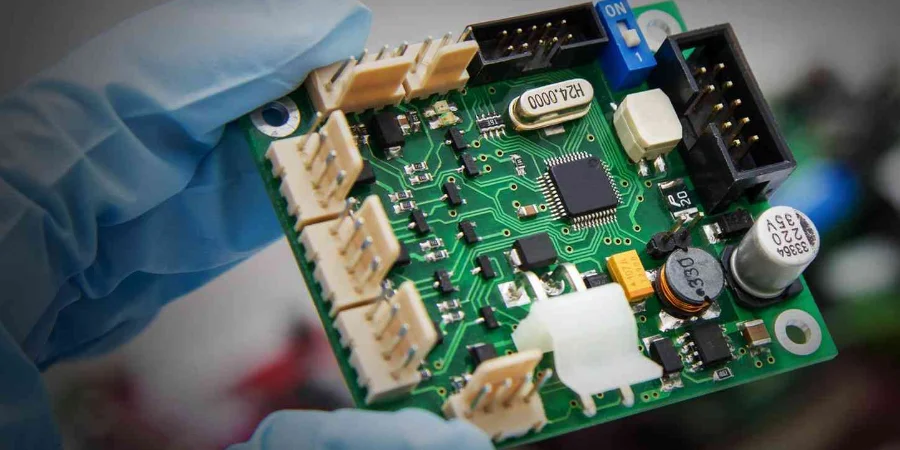

Highleap PCB Factory (HILPCB) delivers industry-leading PCB First Article Inspection services through state-of-the-art inspection equipment, certified quality professionals, and integrated quality management systems supporting diverse PCB technologies from single-double layer PCB to complex rigid-flex PCB assemblies.

Professional Inspection Infrastructure:

Our facility features coordinate measuring machines, automated optical inspection systems, X-ray analysis platforms, and specialized electrical test equipment with comprehensive validation capabilities across diverse applications. ISO 9001 and AS9100 certified quality systems ensure consistent procedures and accurate documentation while experienced quality engineers provide expert analysis and process optimization recommendations.

Manufacturing execution system integration maintains statistical process control and quality traceability throughout production lifecycles with expedited FAI services minimizing inspection cycle times for time-critical projects while maintaining comprehensive validation standards.

Integrated Manufacturing Solutions:

HILPCB seamlessly integrates FAI services with complete PCB manufacturing and assembly capabilities including turnkey assembly and SMT assembly programs. Our flexible approval processes accommodate diverse customer requirements enabling rapid production startup following first article approval with continuous quality monitoring and improvement throughout volume manufacturing operations.