HILPCB delivers professional WiFi PCB manufacturing and assembly solutions for wireless communication devices. Our specialized WiFi PCB services support consumer electronics, enterprise networking equipment, and IoT devices requiring reliable wireless connectivity and exceptional RF performance.

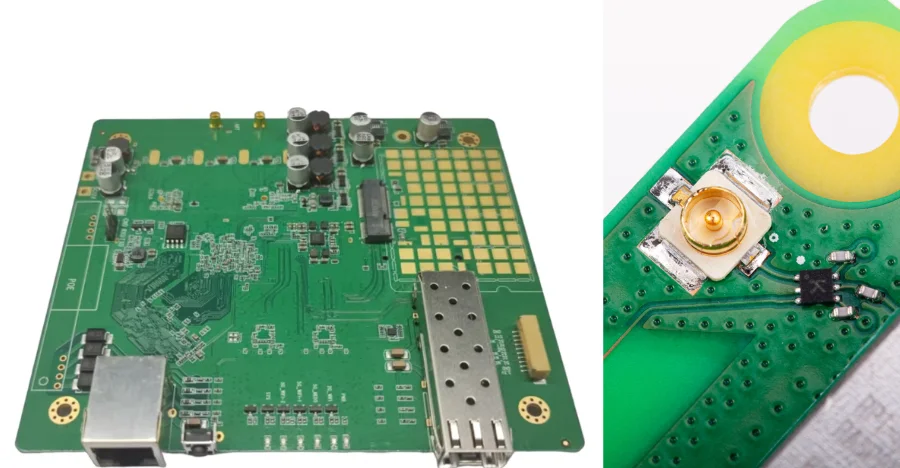

Modern WiFi devices demand sophisticated PCB designs integrating RF transceivers, antenna systems, and power management within compact form factors. Our expertise covers WiFi router PCB manufacturing, wireless module assembly, and complete turnkey solutions for 802.11 applications.

WiFi PCB Design Requirements and RF Considerations

WiFi PCB manufacturing requires careful attention to RF design principles and signal integrity across 2.4 GHz and 5 GHz frequency bands. The primary challenges include maintaining controlled impedance, minimizing interference, and optimizing antenna performance within space-constrained devices.

Essential WiFi PCB Design Elements:

• RF Circuit Layout: Optimized placement of WiFi chipsets, power amplifiers, and antenna matching networks to minimize signal loss and electromagnetic interference

• Impedance Control: Precision 50Ω transmission lines for antenna feeds and RF interconnections with tolerance within ±10% for optimal signal transfer

• Ground Plane Design: Continuous ground planes providing low-impedance return paths and effective electromagnetic shielding for sensitive RF circuits

• Component Integration: Strategic placement of WiFi modules, power management, and digital processing components to prevent interference and optimize thermal performance

WiFi PCB designs must accommodate dual-band operation with separate RF paths for 2.4 GHz and 5 GHz frequencies. High-frequency PCB substrates ensure stable electrical properties across operating frequencies while maintaining low insertion loss critical for wireless performance.

MIMO and Antenna Implementation:

Modern WiFi devices increasingly utilize MIMO technology requiring multiple antenna elements with precise isolation characteristics. Antenna diversity implementations demand careful PCB layout to achieve >20 dB isolation between antenna ports while maintaining compact form factors.

WiFi router PCB designs often integrate patch antennas directly onto the circuit board, requiring accurate dimensional control and proper ground plane clearances. External antenna connections utilize precision RF connectors with consistent 50Ω impedance matching.

WiFi PCB Manufacturing Processes and Materials

Professional WiFi PCB manufacturing employs advanced fabrication techniques and specialized materials optimized for wireless communication applications. Material selection directly impacts RF performance, signal integrity, and long-term reliability of WiFi devices.

Substrate Material Selection:

Rogers PCB materials including RO4003C and RO4350B provide excellent dielectric stability and low loss characteristics essential for high-performance WiFi applications. These materials maintain consistent electrical properties across temperature variations while minimizing signal attenuation.

For cost-effective WiFi implementations, enhanced FR4 PCB substrates offer adequate performance for consumer applications. However, enterprise-grade WiFi equipment benefits from premium RF materials ensuring optimal wireless range and data throughput.

Manufacturing Excellence:

• Precision Drilling: Controlled aspect ratio drilling ensures reliable via formation and consistent impedance characteristics throughout the WiFi PCB stackup

• Copper Quality: Low-profile copper treatments minimize conductor losses at WiFi frequencies while providing excellent solderability for component assembly

• Layer Registration: Advanced alignment techniques maintain interlayer registration within ±25 μm ensuring proper differential pair matching and controlled impedance

• Surface Finish: ENIG (Electroless Nickel Immersion Gold) provides superior contact resistance and long-term reliability for RF connections and fine-pitch components

Quality Control and Testing:

Comprehensive WiFi PCB testing includes impedance measurements, signal integrity analysis, and RF performance verification. Automated optical inspection (AOI) validates assembly quality while electrical testing ensures proper functionality across all circuit paths.

Environmental testing validates WiFi PCB performance across operating temperature ranges from -40°C to +85°C for industrial applications. Thermal cycling and humidity exposure testing ensure reliable operation in demanding environments.

WiFi PCB Assembly and Component Integration

Professional WiFi PCB assembly requires precision placement and soldering techniques for RF components, ensuring optimal electrical performance and long-term reliability. Component selection and assembly processes directly impact wireless communication quality and regulatory compliance.

Critical Assembly Considerations:

WiFi chipsets and RF components demand precise temperature control during reflow soldering to prevent thermal damage while ensuring reliable solder joint formation. SMT assembly processes utilize specialized reflow profiles optimized for WiFi components with strict temperature ramp rates and peak temperature control.

Fine-pitch component placement requires exceptional accuracy with tolerances within ±25 μm for critical RF devices. Advanced pick-and-place equipment ensures proper component orientation and placement consistency essential for WiFi performance optimization.

Component Technologies:

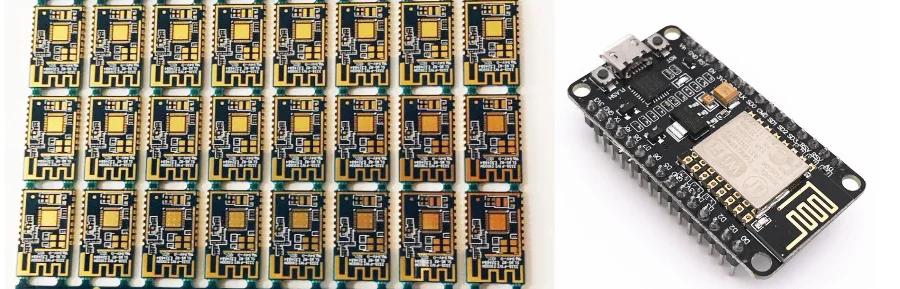

• WiFi Modules: System-on-chip solutions integrating RF transceivers, baseband processing, and antenna interfaces within compact BGA or LGA packages

• Power Amplifiers: Linear amplifiers providing sufficient transmit power while maintaining spectral purity and efficiency requirements for regulatory compliance

• RF Switches: Low-loss switching elements enabling antenna diversity and band selection with minimal insertion loss and excellent isolation characteristics

• Crystal Oscillators: High-stability frequency references ensuring accurate channel spacing and timing synchronization essential for WiFi protocol compliance

Advanced Assembly Techniques:

HDI PCB construction enables ultra-compact WiFi module designs with multiple via-in-pad structures supporting high-density component integration. Sequential lamination processes accommodate complex routing requirements while maintaining signal integrity.

Specialized handling procedures for moisture-sensitive WiFi components include proper storage, baking, and assembly within controlled timeframes preventing component degradation and ensuring long-term reliability.

WiFi Device Applications and Manufacturing Solutions

WiFi PCB manufacturing serves diverse applications from consumer electronics to enterprise networking equipment, each requiring specific design considerations and manufacturing approaches. Understanding application requirements enables optimal PCB design and assembly strategies.

Consumer WiFi Devices:

Smartphone and tablet WiFi implementations prioritize miniaturization and power efficiency. Compact WiFi module PCB designs integrate antenna elements within limited space constraints while maintaining adequate wireless performance for typical usage scenarios.

Smart home devices including WiFi-enabled appliances, security cameras, and IoT sensors require cost-effective WiFi PCB solutions with reliable connectivity and low power consumption. Single-layer and double-layer PCB designs often provide sufficient functionality for basic WiFi connectivity requirements.

Enterprise and Industrial Applications:

WiFi router PCB manufacturing for enterprise applications demands exceptional RF performance, thermal management, and reliability. Multi-layer PCB constructions with dedicated power and ground planes ensure stable operation under high-traffic conditions.

Industrial WiFi devices operating in harsh environments require robust PCB designs with enhanced thermal capability and environmental protection. High thermal PCB substrates facilitate heat dissipation while maintaining electrical performance across extended temperature ranges.

Automotive WiFi Integration:

Vehicle WiFi systems require automotive-qualified PCB manufacturing processes meeting stringent reliability and safety standards. WiFi PCB designs must accommodate extreme temperature variations, vibration resistance, and electromagnetic compatibility requirements specific to automotive environments.

Advanced driver assistance systems (ADAS) and infotainment platforms integrate WiFi connectivity for cloud services, software updates, and passenger connectivity requiring high-performance WiFi PCB implementations with exceptional reliability.

Professional WiFi PCB Services and Support

HILPCB provides comprehensive WiFi PCB manufacturing and assembly services from prototype development through high-volume production. Our engineering expertise ensures optimal WiFi performance while maintaining cost-effectiveness and regulatory compliance for global markets.

Complete Manufacturing Services:

• Design Support: RF engineering consultation optimizing WiFi PCB layouts for maximum performance and manufacturability using advanced simulation tools

• Prototype Development: Rapid prototyping services enabling design verification and performance validation before committing to production volumes

• Volume Manufacturing: Scalable production capabilities supporting quantities from hundreds to millions of WiFi PCBs with consistent quality and delivery performance

• Testing and Validation: Comprehensive testing including RF performance verification, protocol compliance, and environmental qualification ensuring reliable wireless operation

Assembly and Integration:

Complete turnkey assembly services include component sourcing, precision assembly, testing, and packaging. Our supply chain management ensures component availability and cost optimization for WiFi PCB projects.

Quality systems including ISO 9001:2015 certification ensure consistent manufacturing processes and full traceability throughout production. Automotive applications benefit from additional quality standards ensuring exceptional reliability for vehicle integration.

Technical Expertise:

Our engineering team provides design for manufacturing (DFM) analysis identifying potential issues early in the development process. Impedance calculator tools and simulation capabilities optimize WiFi PCB designs for maximum performance and yield.

Environmental compliance including RoHS and REACH certification ensures global market access while supporting sustainability initiatives. Comprehensive documentation and test reports facilitate regulatory approval processes for WiFi-enabled products.

Frequently Asked Questions About WiFi PCB Manufacturing

**Q: What are the key considerations for WiFi PCB manufacturing? **

A: WiFi PCB manufacturing requires controlled impedance routing, appropriate substrate materials for RF performance, proper ground plane design, and precise component placement to ensure optimal wireless connectivity and regulatory compliance.

Q: Which materials are best for WiFi PCB applications?

A: Rogers materials provide excellent RF performance for high-end applications, while quality FR4 substrates work well for cost-sensitive WiFi devices. Material selection depends on frequency requirements, performance specifications, and cost targets.

Q: How do you ensure WiFi PCB quality and performance?

A: We implement comprehensive testing including impedance verification, RF performance measurements, assembly inspection, and functional testing. Environmental qualification ensures reliable operation across specified temperature and humidity ranges.

Q: Can you support both prototype and production WiFi PCB requirements?

A: Yes, we provide complete WiFi PCB services from initial prototyping through high-volume manufacturing with scalable production capabilities and consistent quality standards throughout all project phases.

Q: What assembly services do you provide for WiFi PCBs?

A: Our services include precision SMT assembly, component sourcing, testing, and complete turnkey solutions. We handle all aspects of WiFi PCB assembly from fine-pitch components to final system integration and testing.