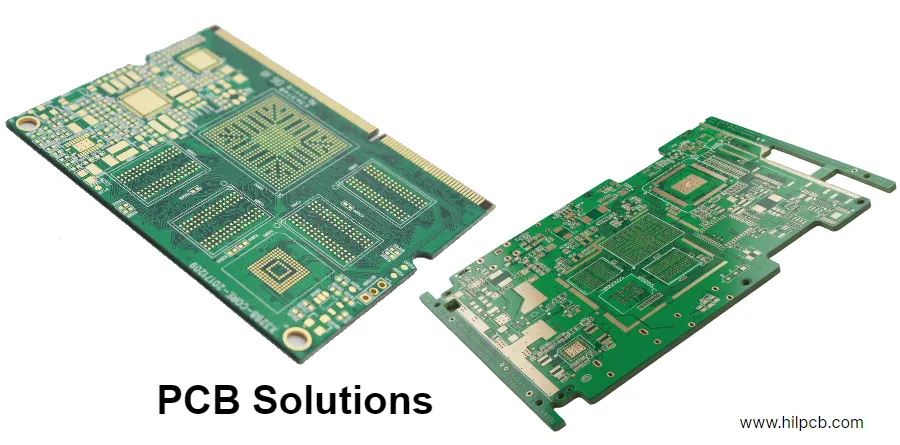

Standard manufacturing approaches work for conventional electronics. But challenging applications—extreme environments, regulatory requirements, unique performance demands, novel technologies—require customized PCB solutions beyond catalog capabilities. Off-the-shelf processes cannot address thermal extremes in aerospace, contamination resistance for medical devices, signal integrity at multi-gigabit speeds, or mechanical constraints in wearables.

PCB solutions differ from basic PCB Manufacturing by emphasizing problem-solving over order-taking. Instead of executing specifications, solution providers engage engineering resources understanding application context, identifying optimal approaches, developing customized processes addressing specific challenges. This methodology treats each project as unique problem requiring tailored solutions.

HILPCB specializes in engineered PCB solutions for applications where standard approaches prove insufficient. Our solutions methodology emphasizes understanding requirements, collaborative engineering, process development delivering boards meeting demanding performance, reliability, and environmental specifications.

Application-Specific PCB Solutions by Industry

Different applications impose distinct requirements on PCB Design and manufacturing. Solution providers must understand these contexts to propose appropriate approaches.

Automotive PCB Solutions:

- ADAS systems: Automotive radar (77-81 GHz), camera modules, lidar interface boards

- Powertrain electronics: Engine control, transmission control, high-temperature (125°C+) operation

- EV power management: Heavy copper (6-12oz), thermal management, high-voltage isolation

- Infotainment: High-speed interfaces (HDMI, USB, Ethernet), display drivers

- Requirements: IATF 16949 certification, AEC-Q qualification, PPAP documentation, extended temperature (-40 to +125°C)

Medical Device PCB Solutions:

- Diagnostic equipment: Precision analog, noise reduction, safety isolation

- Wearable health monitors: Flex/rigid-flex, biocompatible materials, low power

- Implantable devices: Miniature constructions, hermetic sealing, sterilization-compatible

- Patient monitoring: Medical-grade isolation, EMI compliance, high reliability

- Requirements: ISO 13485 certification, IPC Class 3 workmanship, biocompatible coatings, sterilization testing

Aerospace & Defense PCB Solutions:

- Avionics: Rigid-flex for space/weight constraints, extended temperature, vibration resistance

- Radar systems: High-frequency Rogers/Taconic materials, tight impedance control

- Satellite communications: PTFE substrates, controlled outgassing, radiation hardening

- Military electronics: Conformal coating, moisture resistance, MIL-STD compliance

- Requirements: AS9100 certification, detailed documentation, material traceability, ITAR compliance

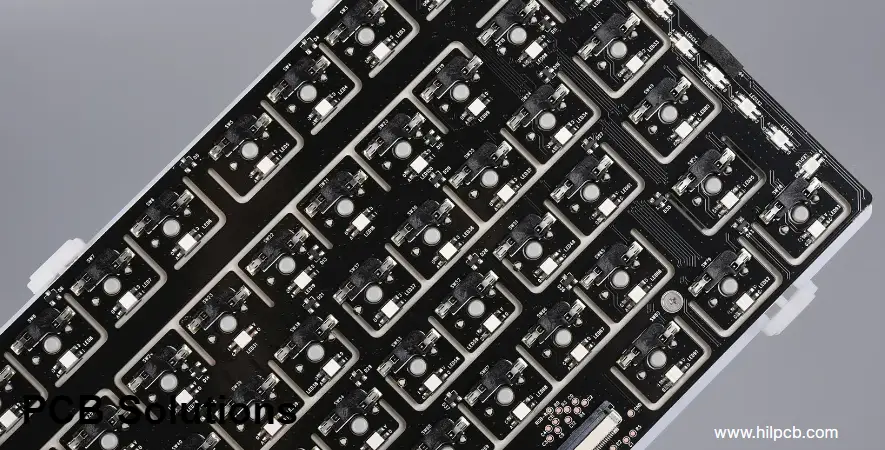

LED & Lighting PCB Solutions:

- High-power LED: Aluminum core (1-3 W/mK) or copper core (200-400 W/mK)

- LED strips: Thin aluminum substrates, cost-effective volume production

- Automotive lighting: Copper core with high reliability, thermal cycling resistance

- Smart lighting: Integrated wireless (WiFi/Bluetooth), driver circuits, dimming control

- Requirements: Thermal interface materials, heat sink attachment, color consistency

Industrial IoT PCB Solutions:

- Sensor modules: Precision analog, calibration, environmental protection (IP67/68)

- Wireless gateways: Multi-protocol support (WiFi, Bluetooth, LoRa, NB-IoT), antenna integration

- Industrial controls: Extended temperature, noise immunity, rugged conformal coating

- Edge computing: High-speed processing, thermal management, compact form factors

- Requirements: Wide temperature range, EMI/EMC compliance, long product lifecycles

Specialty Material PCB Solutions

Standard FR4 cannot meet all performance requirements. Material selection dramatically affects electrical, thermal, and environmental performance through specialized PCB Fabrication processes.

High-Frequency PCB Solutions:

- Rogers materials: RO4003C/4350B (1-10 GHz cost-effective), RT/duroid 5880/6002 (10-77 GHz ultra-low loss)

- Taconic solutions: TLY-5, RF-35 for military/aerospace RF systems

- Arlon options: 25N, DiClad for high-reliability applications

- Isola high-speed: IS680, Astra MT77 for 25+ Gbps digital (PCIe Gen4/5, 100G Ethernet)

- Nelco materials: N4000-13 for controlled Dk impedance-critical designs

- Process requirements: Lower lamination temps, specialized drilling, ±3Ω impedance tolerance

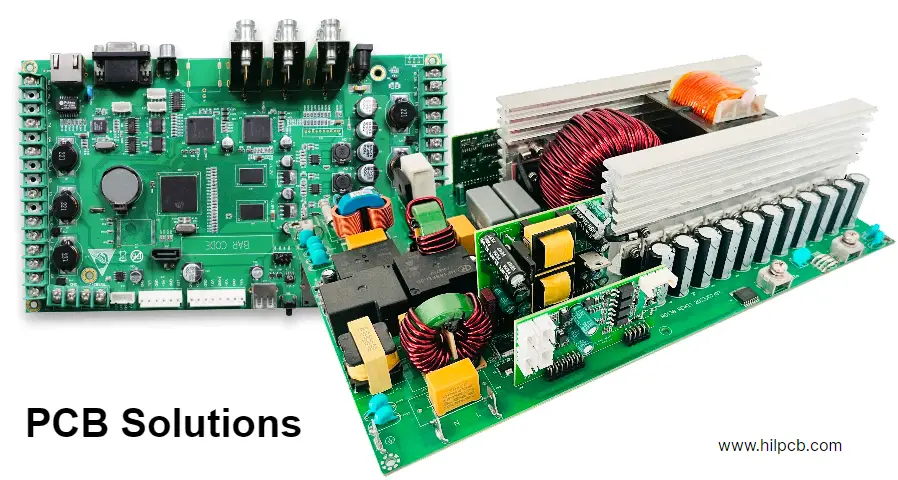

Thermal Management Solutions:

- Metal core PCB: Aluminum (cost-effective, 1-10 W/mK) or copper (maximum performance, 200-400 W/mK)

- Thick copper boards: 3-20oz copper for high-current distribution and heat spreading

- Ceramic substrates: Alumina (Al₂O₃) or Aluminum Nitride (AlN 170-200 W/mK)

- Thermal via arrays: Optimized via placement for heat conduction

- Hybrid constructions: Metal core with FR4 layers for complex designs

- Applications: Power electronics, LED lighting, motor drives, EV charging, RF power amplifiers

High-Temperature Solutions:

- Polyimide rigid boards: Glass transition >260°C for extreme environments

- High-Tg FR4: Tg 170-180°C for lead-free assembly and elevated operation

- PTFE materials: Temperature-stable for aerospace applications

- Process modifications: Extended cure cycles, specialized moisture control

- Applications: Automotive under-hood, downhole drilling, aerospace, industrial processes

Flex & Rigid-Flex Solutions:

- Polyimide flex: Kapton-based for static or dynamic flexing

- Rigid-flex constructions: Combines rigid sections (components) with flex interconnects (3D packaging)

- Adhesiveless systems: Better electrical performance, thermal stability

- Dynamic flex testing: Validates reliability under repeated bending

- Applications: Wearables, medical implants, aerospace, smartphones, compact IoT

Our specialty material expertise extends beyond traditional PCB Services, providing engineered solutions optimized for each application's unique demands.

Environmental Protection & Reliability Solutions

Harsh environments demand protection beyond standard PCB Production processes. Specialized treatments ensure long-term reliability.

Conformal Coating Solutions:

- Acrylic: Good moisture protection, easy rework, moderate temperature (-65 to +125°C)

- Silicone: Extreme temperature range (-65 to +200°C), flexible, moisture resistant

- Urethane: Excellent chemical and abrasion resistance, difficult to rework

- Parylene: Ultra-thin vapor-deposited coating, pinhole-free, biocompatible

- Epoxy: Maximum environmental protection, permanent (no rework possible)

- Application methods: Automated spray (selective), dip coating (full coverage), brush (manual/prototypes)

Potting & Encapsulation:

- Epoxy potting: Maximum mechanical/environmental protection, excellent thermal conductivity

- Polyurethane: Good protection with flexibility, easier rework than epoxy

- Silicone: Extreme temperature, excellent vibration damping

- Vacuum potting: Removes air bubbles ensuring void-free encapsulation

- Applications: Outdoor electronics, underwater equipment, high-vibration, tamper-resistant units

Environmental Testing:

- Temperature cycling: -40 to +125°C validates performance across operating range

- Thermal shock: Rapid temperature changes test material compatibility

- Humidity exposure: 85°C/85% RH accelerated aging

- Salt spray: Corrosion resistance for marine/coastal environments

- Vibration testing: Simulates transportation and operational conditions

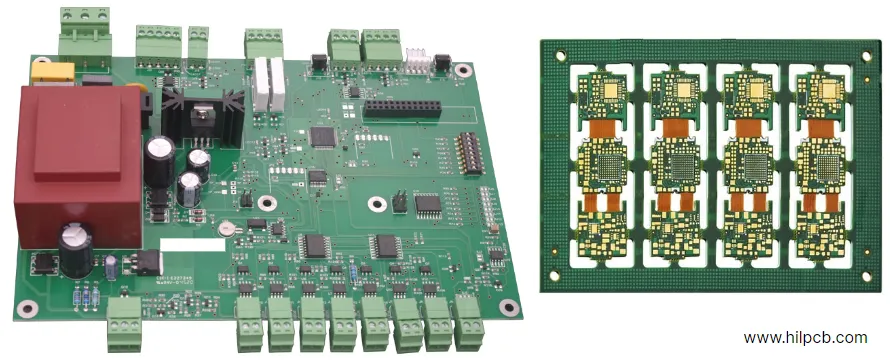

Design & Engineering Solutions

Complex applications require engineering collaboration with experienced PCB Manufacturer teams beyond basic manufacturing services.

Custom Design Services:

- Application analysis: Deep dive into operating conditions, performance requirements, constraints

- Technology selection: Recommends optimal materials and processes for specific needs

- Stackup optimization: Layer arrangement for signal integrity, impedance, thermal

- Risk assessment: Identifies technical challenges and reliability concerns

Advanced Simulation & Analysis:

- Signal integrity: Pre-layout SI simulation, post-layout verification, eye diagram analysis

- Power integrity: PDN analysis, decoupling optimization, voltage drop calculation

- Thermal modeling: Component temperature prediction, heat spreading design

- EMI/EMC analysis: Identifies potential emissions or susceptibility issues

Prototype Validation:

- Design iteration support: Rapid PCB Prototyping for multiple design variants

- Performance testing: Electrical characterization, thermal imaging, RF measurement

- Reliability testing: Temperature cycling, vibration, accelerated life testing

- Failure analysis: Root cause investigation, corrective recommendations

Production Optimization:

- DFM refinement: Manufacturability improvements for yield and cost

- Process development: Custom parameters for unique constructions

- Test program creation: Electrical and functional test development

- Documentation: Manufacturing instructions, quality criteria, traceability

HILPCB Solutions Approach

Application Expertise:

- Automotive: IATF 16949 certified, AEC-Q qualification, PPAP documentation

- Medical: ISO 13485 certified, biocompatible materials, sterilization-compatible

- Aerospace: AS9100 certified, material traceability, MIL-STD compliance

- LED/Lighting: Metal core expertise, thermal management, driver integration

- Industrial IoT: Wide temperature, EMI hardened, ruggedized construction

Material Capabilities:

- High-frequency: Rogers (complete series), Taconic, Arlon, Isola, Nelco

- Thermal management: Aluminum/copper core, thick copper (3-20oz), ceramics

- High-temperature: Polyimide, high-Tg FR4, PTFE materials

- Flex/rigid-flex: Polyimide-based constructions, adhesiveless systems

- Specialty: Transparent glass/PET, BT resin, ceramic-filled, custom hybrids

Engineering Services:

- Custom design: Application-specific layout and optimization

- Simulation: SI/PI/thermal/EMI analysis and validation

- Process development: Novel constructions and material combinations

- Testing support: Custom fixtures, environmental validation, certification assistance

Quality & Compliance:

- ISO 9001, AS9100, ISO 13485, IATF 16949 certified

- IPC Class 3 workmanship available

- Comprehensive testing (electrical, impedance, environmental)

- Full documentation and traceability

From challenging requirements to engineered solutions, HILPCB delivers custom PCB Assembly and complete manufacturing addressing unique demands of advanced applications with proven expertise in specialty materials, complex constructions, and regulatory compliance. Our integrated approach as a comprehensive PCB Company ensures seamless coordination from design through production.