Your facility runs equipment from 2005. Original manufacturer stopped supporting it in 2018. Replacement equipment costs $850,000. But the old system works perfectly - if you can keep it running.

The problem? Critical circuit boards. When they fail, you're stuck. No spares. No supplier. Just expensive downtime while scrambling for solutions.

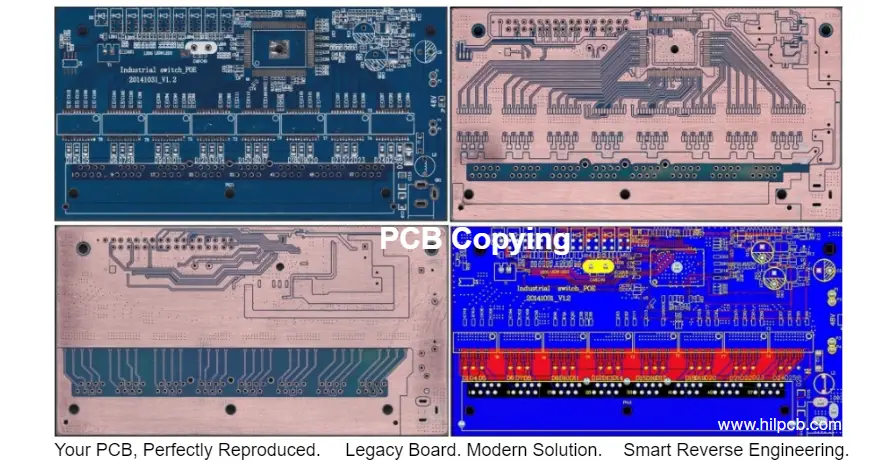

Smart maintenance teams solve this before crisis hits. PCB copy creates spare board inventory from working samples - strategic insurance against future failures at fraction of replacement cost.

Who Needs PCB Copying? (Strategic Maintenance Planning)

PCB copy serves maintenance teams managing legacy equipment strategically, not crisis managers fighting fires. Key differences from emergency services:

Maintenance Manager Perspective: You're planning 6-12 months ahead. Budget approved. Maintenance window scheduled. Equipment still running fine. But you know certain boards are aging, components getting harder to find, and eventually something will fail. You want spares on shelf before that happens.

Industries Benefiting Most:

Manufacturing Facilities: CNC machines, injection molding equipment, automated assembly lines from 1990s-2000s remain productive. OEM support ended, but machines run profitably. Copying creates spare boards for controllers, drives, HMIs preventing production disruptions. Our PCB inspection services help identify which boards to copy first.

Medical Institutions: Hospital imaging equipment (CT, MRI, X-ray from 2000-2010) still provides diagnostic value. New equipment costs $500,000-$2,000,000. Copying power supplies, interface boards, control electronics extends equipment life 5-10 years. Regulatory compliance maintained through exact duplication.

Telecommunications: Cell tower equipment, microwave links, switching systems deployed 15-20 years ago. Infrastructure investment amortized, equipment reliable, but electronics fail occasionally. Copying builds spare inventory supporting geographically distributed infrastructure.

Process Industries: Chemical plants, refineries, water treatment use PLCs and control systems proven reliable over decades. Complete system modernization costs millions and risks introducing new problems. Copying maintains existing investment through our PCB engineering approach.

The Preventive Copying Process (Not Emergency Response)

Unlike emergency PCB cloning, copying follows deliberate, cost-optimized process:

Phase 1: Sample Selection and Documentation (Week 1) Maintenance team identifies critical boards and ships working samples for analysis. We perform non-destructive evaluation - comprehensive photography, component cataloging, electrical characterization, X-ray imaging for multilayer boards. Your sample board returns to you undamaged for continued operation.

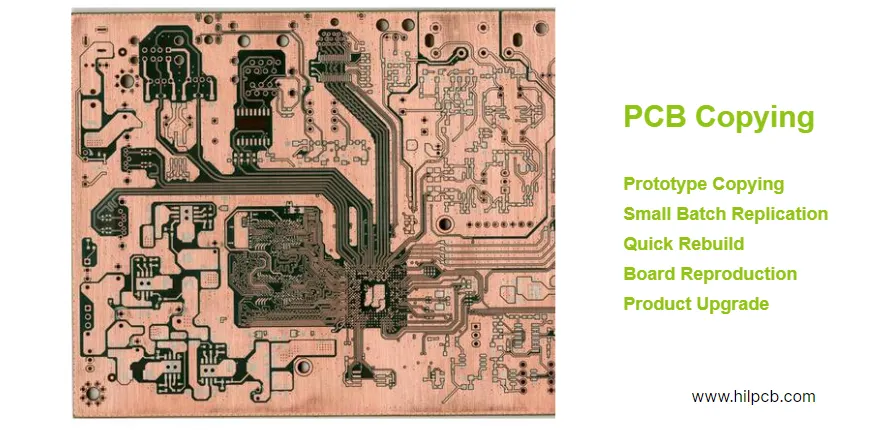

Phase 2: Engineering and Component Sourcing (Week 2-3) Layout recreation from physical board measurements. Component research identifies availability and alternatives for obsolete parts. Unlike emergency rush, we have time to find cost-effective sources, qualify alternatives properly, and optimize for reliability rather than speed.

Phase 3: Prototyping and Validation (Week 3-4) First article production of 2-5 boards. Side-by-side functional testing against your original confirms proper operation through our PCB testing protocols. Any discrepancies corrected before volume production. You receive prototype for in-system validation before committing to full order.

Phase 4: Production Quantities (Week 4-6) After validation, production quantities manufactured. Typical orders: 10-50 boards depending on equipment criticality and failure history. Quality documentation package includes: component traceability, test records, handling/storage guidelines, reorder procedures.

Total Timeline: 4-6 Weeks Not emergency fast, but strategically paced for cost optimization and quality assurance.

Solving Component Obsolescence Strategically

Unlike emergency situations requiring any solution fast, strategic copying allows proper component management:

Component Lifecycle Analysis: We research every component's lifecycle status. Identify which parts remain in production, which face obsolescence, which already discontinued. This informs long-term planning decisions through our PCB development expertise.

Three Approaches to Obsolete Components:

1. New Old Stock (NOS) Procurement: Find remaining inventory from authorized distributors or reputable brokers. Purchase sufficient quantity for planned spare inventory plus safety margin. Lock in supply now before completely gone.

2. Alternative Component Qualification: Identify modern replacements with equivalent specifications. Critical difference: we have time for thorough qualification:

- Electrical parameter verification across operating range

- Thermal characteristic confirmation

- Long-term reliability assessment

- In-system functional testing

- Documentation for regulatory compliance

3. Design Optimization: When obsolescence severe, consider minor board redesign using modern components. Maintains mechanical fit and interface compatibility while substituting available parts. More investment upfront, but ensures 10+ year spare availability.

Component Counterfeit Prevention: Preventive copying allows proper sourcing through authorized channels. Unlike emergency situations potentially forcing questionable sources, strategic copying uses verified authentic components only.

Building Complete Spare Programs

Smart maintenance teams integrate PCB copying into comprehensive spare parts strategy:

Critical Board Prioritization: Not all boards equally important. Prioritize copying based on:

- Failure history: Boards failing every 2-3 years need spare inventory

- Lead time: Boards taking 16+ weeks from OEM need preventive copying

- Cost impact: Boards where failure causes $100,000+ downtime losses

- Equipment criticality: Single points of failure in production lines

Inventory Management: Maintain appropriate spare levels:

- Critical single-point failures: 3-5 spares minimum

- Redundant systems: 2-3 spares adequate

- Failure rate consideration: Replace consumed spares proactively

Documentation and Traceability: Each copied board comes with:

- Component source documentation

- Test data and validation records

- Storage and handling guidelines

- Installation procedures

- Troubleshooting guides

- Reorder information with locked-in pricing

Ongoing Support: Design files archived for future reorders. Component substitution alternatives documented. Manufacturing process captured. Typical reorder lead time: 2-3 weeks versus 4-6 weeks initial order.

Quality Standards for Maintenance Spares

Spare boards sitting on shelf 5-10 years before use require rigorous quality:

Manufacturing Quality: IPC-A-610 Class 2 minimum (Class 3 for medical/aerospace). Conformal coating for environmental protection. Proper ESD handling and storage packaging. Shelf life considerations for electrolytic capacitors and batteries.

Functional Validation: Every board undergoes comprehensive testing:

- Power supply regulation and ripple

- Signal integrity across frequency range

- Interface communication protocols

- Load testing under realistic conditions

- Environmental screening (thermal, humidity, vibration)

Long-Term Storage: Guidance provided for proper storage: ESD protection, humidity control (40-60%), temperature stability (15-25°C), periodic testing schedule (annually recommended), rotation strategy for aging components.

Warranty and Support: Standard warranty: 2 years from delivery against manufacturing defects. Extended support available: we maintain design files and component alternates for minimum 10 years, enabling future reorders as spare inventory consumed.

Copying vs Alternative Strategies

PCB copying isn't always optimal approach. Compare alternatives:

When Copying Best Choice:

- Equipment still productive and profitable

- OEM support ended or became prohibitively expensive

- Replacement equipment not justified economically

- Multiple units requiring spare support

- Time available for proper engineering (not emergency)

When Reverse Engineering Better: Need complete design documentation for modifications? PCB reverse engineering creates schematics and editable design files. Enables future improvements, variants, and design understanding. More expensive ($8,000-$25,000), longer timeline (6-12 weeks), but provides flexibility beyond simple copying.

When Equipment Modernization Justified: Extensive component obsolescence making copying impractical, opportunity to improve performance/efficiency significantly, long-term (15+ years) continued operation planned, budget available for capital investment.

Why Choose HILPCB for Strategic Copying

Maintenance-Focused Approach: We understand maintenance team priorities: cost control, planning predictability, minimal disruption, regulatory compliance. Not emergency response mentality - deliberate strategic planning.

Component Sourcing Expertise: Global procurement network. Relationships with 100+ authorized distributors and vetted obsolete parts specialists. Counterfeit prevention protocols. Component lifecycle monitoring and alternative recommendations.

Quality and Compliance: ISO9001, ISO13485 certified manufacturing. FDA-compliant documentation for medical devices. AS9100 compliance for aerospace. Traceability supporting regulatory requirements.

Complete Service Integration:

- PCB repair for failed boards while building spare inventory

- PCB rework for implementing engineering changes

- PCB replication for scaling to production quantities

- Inventory management programs

- Preventive maintenance consulting

Long-Term Partnership: We archive your designs permanently. Component alternates documented for future. Manufacturing processes optimized and repeatable. Reorder pricing locked for 24 months. Ongoing support as your spare inventory needs evolve.

Smart maintenance teams don't wait for failures. They plan ahead, build spare inventory proactively, and sleep better knowing critical boards sit ready on the shelf.

Start building your spare inventory today. Our maintenance engineers will analyze your critical boards, recommend copying priorities, and provide comprehensive cost-benefit analysis for your specific equipment.